Why Moss Removal is Needed in HYDROELECTRIC POWER PLANT

Moss Removal Screens in the context of hydroelectric power plants.

🌊 Why Moss Removal is Needed in HYDROELECTRIC POWER PLANT

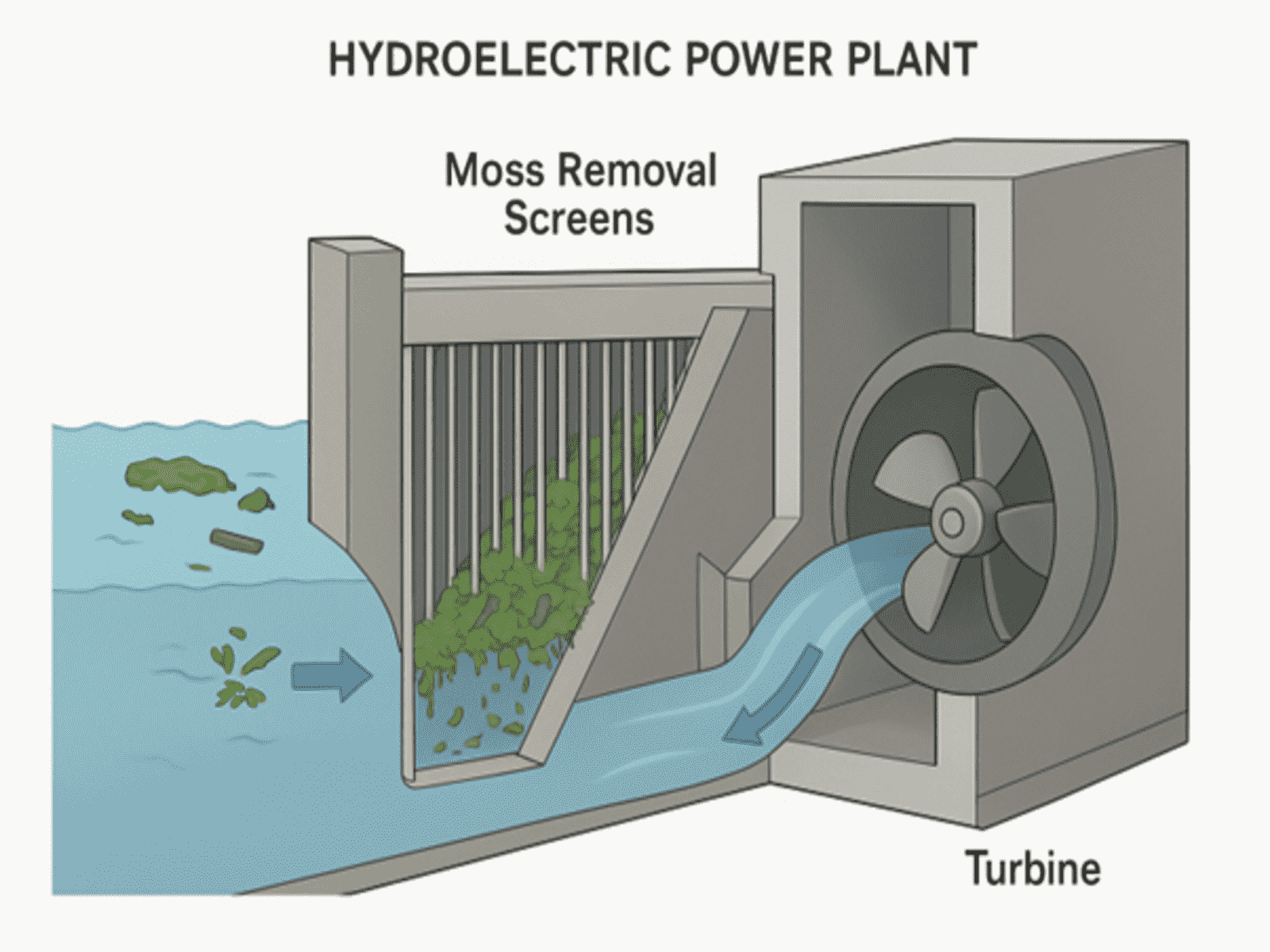

In hydroelectric power plants, raw water is drawn from reservoirs, rivers, or dams and directed towards intake structures → penstocks → turbines.

But, these waters often contain:

- Moss, algae, and aquatic plants (especially in stagnant or slow-moving reservoirs).

- Floating debris (wood, leaves, plastics).

- Silt and sand (depending on catchment geology).

If moss and algae are not controlled:

- They clog intake screens, reducing flow.

- They accumulate in penstocks, causing frictional head losses.

- They damage turbine blades (abrasion, imbalance).

- They increase O&M costs due to frequent shutdowns for cleaning.

⚙️ Moss Removal Screens: Design & Function

Moss removal screens are mechanical or hydraulic barriers installed at the intake structures of hydroelectric plants.

They filter out floating and suspended biomass before water enters the turbine system.

1. Fixed Trash Racks / Screens

- Constructed of vertical or inclined steel bars (spacing: 10–100 mm).

- Positioned at the water intake.

- Primary role: block large moss mats and debris.

- Require manual or mechanical raking.

2. Automatic / Mechanical Raking Screens

- Equipped with traveling rakes, combs, or chain-driven scrapers.

- Continuously or intermittently remove moss and deposit it into disposal conveyors.

- Reduces manpower and downtime.

3. Rotary Drum Screens

- Cylindrical drum with fine mesh rotates as water passes.

- Moss and algae accumulate on the surface → brushed/sprayed off.

- Suitable for high biomass loads.

4. Self-Cleaning Intake Screens (Coanda Screens, Wedge Wire Screens)

- Fine wedge-wire slots angled to shed moss.

- Use the shear of water flow to self-clean.

- Effective in reducing maintenance, often used in small hydro plants.

🔄 Supporting Systems

- Backwashing Systems: High-pressure water jets wash moss from screens.

- Trash Conveyor Belts: Transport removed biomass away from intake.

- Automated Control: SCADA-linked raking frequency based on head loss or flow velocity

🌱 Disposal of Removed Moss

Collected moss and aquatic vegetation can be:

- Composted or used as fertilizer/soil conditioner.

- Dried and used in biogas/biomass energy

- Safely disposed to prevent re-entry into water bodies.

📊 Benefits of Moss Removal Screens

- Ensures continuous flow to turbines.

- Prevents turbine damage from biomass ingestion.

- Reduces downtime for maintenance/cleaning.

- Increases plant efficiency & lifespan.

- Environmental compliance: prevents downstream clogging or fish habitat damage.

✅ In short:

Moss removal screens are an essential first line of defense in hydroelectric plants, ensuring smooth water flow, protecting turbines, and maintaining operational efficiency by mechanically or hydraulically removing moss, algae, and floating debris.