Uses of Heat Exchangers

Heat exchangers are unsung heroes in many industries, quietly supporting operations that keep the world turning. Despite this, they are frequently disregarded. In order to transfer thermal energy from one medium to another without allowing the media to mix, these devices are essential. We go over the various applications and sectors that heat exchangers are used in.

The Power of Heat Exchangers

Heat exchangers are clever devices that facilitate the effective transfer of heat between two substances or fluids. They work in commercial buildings, home applications, and industries to carry out a variety of essential tasks. Heat exchangers work on the basic idea of heating or cooling one fluid while heating or cooling another, depending on the application. Efficiency

is increased, expenses are reduced, and energy is conserved as a result of this heat exchange.

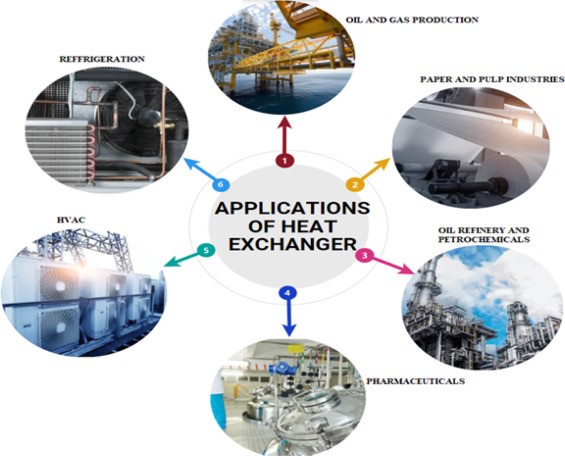

Applications in Industries

-

Heating, Ventilation, and Air Conditioning (HVAC)

Heat exchangers are essential to HVAC systems in order to keep interior spaces comfortable.

By using these systems, heat from exhaust air is recovered and transferred to incoming fresh

air. They greatly lower their energy use and heating expenses by doing this. -

Power Generation

A vital component of power plants are heat exchangers. They create steam to produce

electricity by transferring heat from hot combustion gases to water or other fluids. Nuclear

reactors, gas turbines, and steam turbines all operate on this principle. -

Chemical Processing

Heat exchangers are used in the chemical industry for a variety of purposes, including

condensing vapours, heating and cooling reactive compounds, and regulating temperature

during different chemical operations. -

Oil and Gas

Heat exchangers are essential to the oil and gas sector because they facilitate the production

and transportation of liquefied natural gas (LNG) as well as the heating and cooling of

refinery activities. -

Food and Beverage

Heat exchangers are essential to the food processing industry since they are used to

pasteurise, sterilise, and cool food and drink items. This increases shelf life and guarantees

food safety. -

Pharmaceuticals

Heat exchangers are utilised in the production of pharmaceuticals for procedures like

evaporation, crystallisation, and sterilising. They are essential to preserving the purity and

quality of pharmaceuticals. -

Automotive

Heat exchangers are a component of the engine cooling system in the automotive industry,

which maintains engines running at ideal temperatures. They are involved in air conditioning

systems as well. -

Aerospace

Heat exchangers are used in aerospace applications, such as aircraft and spacecraft, for a

variety of thermal management duties, such as cooling avionics and preserving passenger

comfort. -

Renewable Energy

Heat exchangers are used in renewable energy systems, such solar thermal and geothermal

power plants, to transport heat from renewable sources to produce hot water or electricity. -

Wastewater Treatment

Wastewater treatment facilities employ heat exchangers to recover heat from sewage water,

which is then used to either supply district heating or pre-heat incoming wastewater.

Domestic and Commercial Uses

Applications for heat exchangers are not just found in industry. They improve comfort and

convenience and are present in common appliances:

-

Water Heaters

Heat exchangers use hot exhaust gases from combustion to heat cold water in household and

commercial water heaters, hence increasing energy efficiency. -

Refrigeration and Air Conditioning

Heat exchangers are essential parts of air conditioning and freezers. They make it easier for

the refrigerant’s heat to be removed, which permits cooling. -

Swimming Pools

By effectively heating swimming pool water, heat exchangers increase the swimming season

and save energy expenses.

Specialized Heat Exchanger Types

The variety of uses for heat exchangers has prompted the creation of variants that are suited

to particular requirements. These specialty heat exchangers include, for example:

-

Plate Heat Exchangers

Plate heat exchangers, which have a small design and great heat transfer efficiency, find

application in the food processing, refrigeration, and HVAC industries. -

Shell and Tube Heat Exchangers

These durable heat exchangers are used in chemical processing, oil refineries, and power

plants, among other places. -

Finned Tube Heat Exchangers

Finned tube heat exchangers are frequently used in air-cooling applications, including the

automotive and aerospace sectors, because of their improved heat transfer capabilities. -

Regenerative Heat Exchangers

In order to effectively capture and transport heat in high-temperature applications such as

industrial operations, these specialised heat exchangers are utilised.

Summary

Heat exchangers are a vital and adaptable piece of technology that has a huge, silent impact

on our lives. Their uses are numerous and essential, ranging from preserving energy and

sustaining pleasant interior temperatures to supplying electricity to various industries. They

are essential components of contemporary engineering and sustainability because of their

effectiveness, affordability, and positive effects on the environment. Heat exchangers will

become more and more important as technology develops in our attempts to control heat

transfer processes while reducing energy use and environmental effect.

A broad variety of heat exchangers are designed, supplied, and installed by Waterman

Engineers Australia for a range of industries, including petrochemical plants, fertiliser

production, specialty chemicals, compressors, oil and gas, FPSOs (Floating Production

Storage and Offloading), fertiliser production, and fertiliser production. From compact units

under 5 m² to large-scale units up to 7500 m², they provide solutions for heat exchangers.

With tube lengths reaching up to 13.5 metres, these heat exchangers accommodate a broad

range of shell diameters, from 6″ pipes to around 2.5 metres.

Our heat exchangers are used for falling film, hairpin, double pipe, continuous fin, heating,

cooling, re-boiling, condensing, and electric heating, among other functions. Waterman

Engineers Australia is a dependable partner for streamlining heat transfer procedures in a

variety of industries thanks to their extensive array of solutions.