Water and Effluent Treatment Plants Requirements for Greenfield Projects

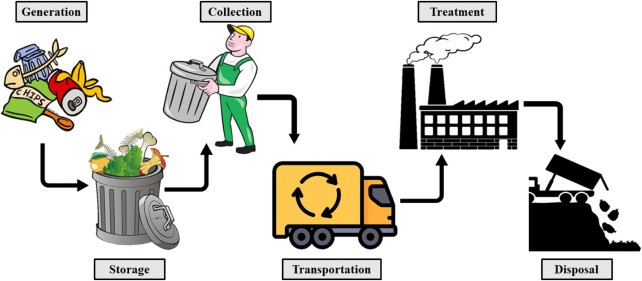

Wastewater treatment plants (WWTPs) are facilities designed to treat and process wastewater before it is discharged back into the environment or reused for various purposes. The primary objective of wastewater treatment plants is to remove pollutants, pathogens, and contaminants from wastewater to protect public health and the environment. Here is an overview of the main processes involved in wastewater treatment plants:

- Preliminary Treatment:

- Primary Treatment:

- Secondary Treatment:

- Advanced Treatment:

- Sludge Treatment:

- Disinfection:

- Effluent Discharge or Reuse:

- Monitoring and Compliance:

Wastewater Treatment Greenfield Projects

In the context of wastewater treatment, greenfield projects refer to the development of new wastewater treatment facilities or infrastructure from scratch, without any existing structures or installations.

Greenfield projects involve building entirely new wastewater treatment plants or upgrading existing facilities to address the growing demand for effective wastewater management. The term “greenfield” emphasizes the development of new facilities as opposed to brownfield projects, which involve refurbishing or expanding existing infrastructure.

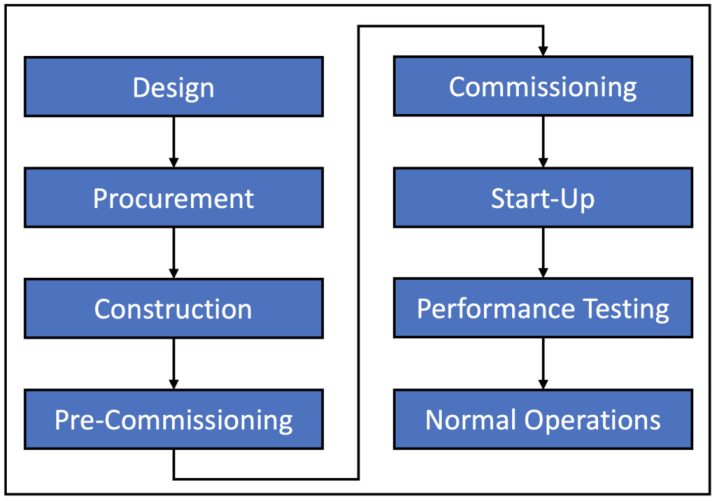

Greenfield projects in wastewater treatment typically encompass the entire process of planning, designing, constructing, and commissioning a new treatment plant. They involve selecting suitable sites, conducting feasibility studies, designing treatment processes, procuring equipment, and establishing the necessary infrastructure for wastewater collection, treatment, and disposal.

The term “greenfield” also emphasizes the opportunity to incorporate innovative and sustainable practices in the design and operation of wastewater treatment plants. Greenfield projects often prioritize energy efficiency, advanced treatment technologies, resource recovery, and environmentally friendly practices. This approach aims to minimize environmental impacts, optimize operational efficiency, and ensure the long-term sustainability of wastewater treatment systems.

Waterman Engineers Australia is a multidisciplinary engineering consultancy that offers various services in the field of water and wastewater treatment. Here is a general overview of how greenfield projects can be applied in water and wastewater treatment plants, which may align with the services offered by Waterman Engineers Australia. Here are some potential applications:

- Design and Engineering: Waterman Engineers Australia may provide design and engineering services for greenfield water and wastewater treatment plants. This includes conducting feasibility studies, site selection, process design, hydraulic and structural design, and the preparation of detailed engineering drawings and specifications.

- Site Selection and Planning: Greenfield projects begin with site selection and comprehensive planning. The project team assesses factors such as water sources, topography, environmental considerations, and population growth projections to identify suitable locations for the treatment plant. Planning involves determining the treatment capacity required, selecting appropriate treatment technologies, and considering the long-term needs of the community or industry being served.

- Treatment Process Selection: Waterman Engineers Australia can assist in selecting appropriate treatment processes for water and wastewater treatment plants. This involves evaluating the specific water quality parameters, regulatory requirements, and desired treatment outcomes to determine the most suitable treatment technologies and processes to be implemented in the greenfield project.

- Infrastructure Development: Waterman Engineers Australia may offer services related to the development of treatment plant infrastructure. This includes the design of treatment units, pumping stations, pipelines, storage tanks, and other necessary components to ensure efficient water and wastewater conveyance, treatment, and distribution.

- Energy Efficiency and Sustainability: Waterman Engineers Australia can focus on incorporating energy-efficient and sustainable practices in greenfield projects. This may involve optimizing treatment processes to minimize energy consumption, integrating renewable energy sources, implementing energy recovery systems, and incorporating green building principles to reduce the environmental impact of the treatment plant.

- Automation and Control Systems: Waterman Engineers Australia may provide expertise in the design and implementation of automation and control systems for water and wastewater treatment plants. This includes the integration of supervisory control and data acquisition (SCADA) systems, remote monitoring and control technologies, and advanced process control strategies to optimize plant performance and ensure efficient operation.

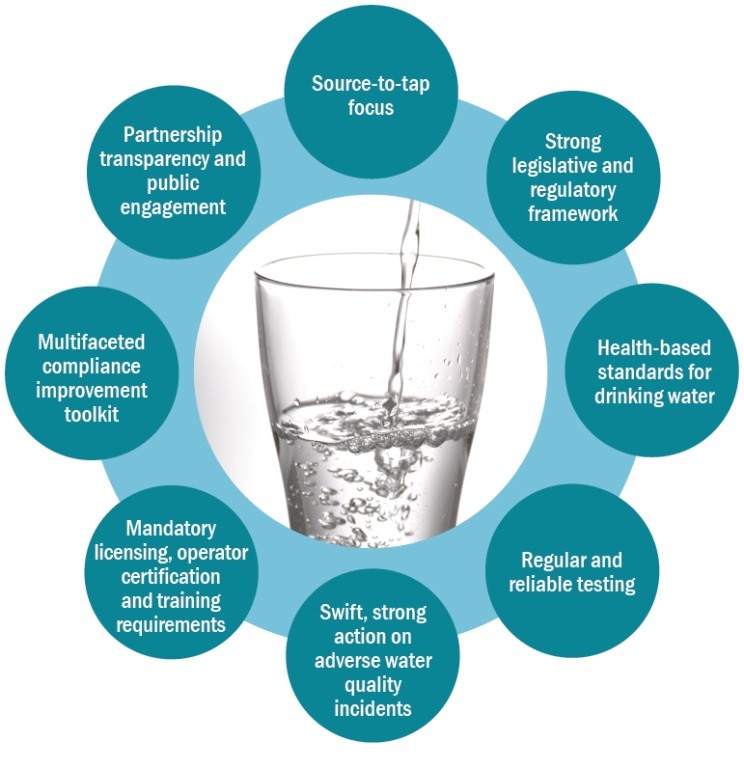

- Water Quality Monitoring: Greenfield projects implement water quality monitoring systems to ensure compliance with regulatory standards. Online monitoring equipment and laboratory analysis are used to measure parameters such as pH, turbidity, dissolved oxygen, and specific contaminants. Continuous monitoring provides real-time data to detect deviations and make necessary adjustments to maintain water quality.

- Regulatory Compliance: Waterman Engineers Australia can help ensure that greenfield projects comply with relevant regulations and standards. They may provide assistance in obtaining necessary permits, conducting environmental impact assessments, and ensuring that the treatment plant meets all applicable water quality and discharge regulations.

- Community Engagement: Greenfield projects prioritize community engagement to address concerns, provide information, and foster public support. Public meetings, communication campaigns, and educational programs can be conducted to raise awareness about the project, its benefits, and the importance of water and wastewater treatment.

- Project Management and Construction Supervision: Waterman Engineers Australia may offer project management and construction supervision services for greenfield projects. This involves overseeing the construction phase, coordinating with contractors, conducting quality control inspections, and ensuring that the project is completed within the specified budget and timeline.

It’s important to note that the specific services offered by Waterman Engineers Australia may vary, and it’s best to consult their official website or contact them directly for detailed information about their expertise and services in greenfield water and wastewater treatment projects.

Effluent Recycling

Effluent recycling refers to the process of treating and reusing wastewater effluent instead of discharging it into the environment. It involves treating the effluent to remove contaminants and impurities, transforming it into high-quality recycled water suitable for various non-potable applications. Effluent recycling offers several benefits, including water conservation, reduced freshwater demand, and environmental sustainability.

The process of effluent recycling typically involves the following steps:

- Wastewater Collection: Wastewater effluent generated from various sources, such as residential, commercial, or industrial activities, is collected through a network of sewer lines or other appropriate collection systems.

- Pre-treatment: The collected wastewater undergoes pre-treatment processes to remove large solids, debris, and any grit or sand that may cause damage to the subsequent treatment equipment. This may involve processes like screening, grit removal, and sedimentation.

- Biological Treatment: After pre-treatment, the effluent is typically subjected to biological treatment processes, such as activated sludge, extended aeration, or sequencing batch reactors. These processes use microorganisms to break down organic matter and reduce the concentrations of nutrients like nitrogen and phosphorus.

- Advanced Treatment: Following biological treatment, advanced treatment technologies are employed to further purify the effluent and achieve the desired water quality for reuse. These technologies may include filtration (such as sand filtration, membrane filtration, or granular media filtration), disinfection (such as chlorination, UV disinfection, or ozonation), and advanced oxidation processes (such as ozone or hydrogen peroxide).

- Recycled Water Storage and Distribution: The treated effluent, now transformed into high-quality recycled water, is stored in reservoirs or tanks dedicated to recycled water storage. From there, it can be distributed through a separate distribution system to end-users for various non-potable applications.

- Non-Potable Reuse Applications: The recycled water can be used for a wide range of non-potable applications, including landscape irrigation, agricultural irrigation, industrial processes, cooling water for power plants or manufacturing facilities, toilet flushing, and other non-potable water demands. The specific reuse applications depend on the quality of the recycled water and the local regulations and requirements.

Application of greenfield projects in effluent recycling

Greenfield projects can be effectively applied in the implementation of effluent recycling systems, which involve treating wastewater effluent to a high-quality standard for reuse purposes. Here are some key applications of greenfield projects in effluent recycling:

- System Design and Engineering: Greenfield projects allow for the design and engineering of effluent recycling systems from scratch. The project team can optimize the design based on the specific requirements of the wastewater source and the desired reuse applications. This includes selecting appropriate treatment processes, designing treatment units, and determining the necessary infrastructure for effluent collection, treatment, storage, and distribution.

- Advanced Treatment Technologies: Effluent recycling projects can incorporate advanced treatment technologies to achieve the desired water quality for reuse. Greenfield projects offer the opportunity to integrate processes like membrane filtration (microfiltration, ultrafiltration, nanofiltration, or reverse osmosis), advanced oxidation processes, activated carbon filtration, or ion exchange. These technologies effectively remove contaminants and produce high-quality recycled water suitable for various applications.

- Reuse Applications: Greenfield projects in effluent recycling can identify and establish suitable reuse applications for the recycled water. This may include irrigation of agricultural lands, landscaping, industrial processes, cooling water, toilet flushing, or groundwater recharge. The design and planning phase of the project can consider the local water demand and the specific needs of the surrounding community or industries to determine the optimal reuse applications.

- Infrastructure Development: Greenfield projects involve the construction of the necessary infrastructure to support effluent recycling systems. This includes the construction of treatment plants, storage tanks or reservoirs for recycled water, and distribution systems for delivering recycled water to end-users. The infrastructure can be designed to meet the anticipated future demand, allowing for scalability and expansion as needed.

- Energy Efficiency and Sustainability: Greenfield projects in effluent recycling emphasize energy efficiency and sustainability. The project team can incorporate energy-efficient equipment and technologies, such as high-efficiency pumps and motors, variable frequency drives, and energy recovery systems. Renewable energy sources, such as solar or wind, can be integrated into the project design to further enhance sustainability and reduce operational costs.

- Water Quality Monitoring and Control: Greenfield projects can implement robust monitoring and control systems to ensure the quality of the recycled water. This involves continuous monitoring of water quality parameters, such as turbidity, pH, disinfectant residuals, and microbial indicators. Automated control systems and data analytics can be utilized to optimize treatment processes and ensure compliance with water quality standards.

- Regulatory Compliance: Greenfield projects in effluent recycling must comply with local, regional, and national regulations related to water quality, health, and environmental protection. This includes obtaining permits and approvals, adhering to water quality standards for recycled water, and meeting discharge limits for any residual effluent. Compliance ensures the safe and environmentally responsible operation of the effluent recycling system.

Greenfield projects provide an excellent opportunity to design and implement efficient and sustainable effluent recycling systems. By integrating advanced treatment technologies, optimizing water reuse applications, and ensuring regulatory compliance, these projects contribute to water conservation, reduce freshwater demand, and promote sustainable water management practices.

Zero Liquid Discharge Systems

Zero liquid discharge (ZLD) systems in wastewater treatment refer to a process that aims to eliminate the discharge of liquid waste streams from industrial or municipal facilities. The goal is to recover and reuse as much water as possible from the wastewater while minimizing the volume of residual liquid waste for disposal. ZLD systems are designed to achieve high levels of water recovery and treat the remaining concentrated waste to meet environmental regulations.

The key components and processes involved in a typical ZLD system include:

- Wastewater Pre-treatment: The incoming wastewater undergoes pre-treatment processes to remove large particles, oil, grease, and other contaminants that could potentially hinder the subsequent treatment steps. This may involve physical processes like screening, sedimentation, and filtration.

- Primary Treatment: After pre-treatment, the wastewater enters the primary treatment stage, where solids and suspended particles are further separated and removed. Processes like clarification, sedimentation, and flotation are commonly used to facilitate the settling and removal of these solids.

- Advanced Treatment: In the advanced treatment stage, the pre-treated wastewater is subjected to additional processes to further purify the water. Advanced treatment technologies such as membrane filtration (microfiltration, ultrafiltration, nanofiltration, or reverse osmosis) are employed to effectively remove dissolved contaminants, salts, and other impurities.

- Concentration and Evaporation: After the advanced treatment stage, the remaining liquid waste, known as concentrate or brine, contains the majority of the impurities and dissolved solids. This concentrate is sent to an evaporation system, which utilizes heat sources (such as thermal energy from waste heat or mechanical vapor compression) to evaporate the water, leaving behind a highly concentrated solution.

- Crystallization: The concentrated solution from the evaporation process is then subjected to crystallization. This step involves controlled cooling or chemical addition to induce the formation of solid crystals, thereby separating and recovering valuable salts or minerals present in the concentrated solution.

- Solids Dewatering and Disposal: The solid waste generated from the crystallization process is dewatered to reduce its moisture content. This can be accomplished through various methods, including mechanical dewatering techniques like filter presses or centrifuges. The dewatered solids are then disposed of in an environmentally responsible manner, such as through landfilling or beneficial reuse.

- Water Condensate Recovery: During the evaporation process, water vapor is generated and can be captured and condensed. This condensate can be collected and treated to meet the required quality standards for reuse within the facility or for other non-potable applications.

Application of Greenfield Projects in Zero Liquid Discharge Systems

Greenfield projects can be applied effectively in the implementation of zero liquid discharge (ZLD) systems. ZLD systems aim to minimize or completely eliminate the discharge of liquid waste streams by recovering and reusing the treated water and concentrating the remaining solids for proper disposal. Here’s how greenfield projects can be applied in ZLD systems:

- Site Selection and Planning: Greenfield projects in ZLD systems begin with careful site selection. The site should have suitable characteristics, such as access to water sources, proximity to industrial or municipal facilities generating wastewater, and availability of space for constructing the treatment plant and associated infrastructure. During the planning phase, the project team assesses the feasibility of implementing ZLD, identifies potential water sources for recycling, and evaluates the required treatment processes.

- Design and Engineering: Greenfield projects allow for the design and engineering of a ZLD system from the ground up. The design phase includes the selection and sizing of treatment units, such as pre-treatment processes (e.g., screening, sedimentation), advanced filtration (e.g., membrane filtration, reverse osmosis), evaporators, crystallizers, and dewatering systems. The design should consider the specific characteristics of the wastewater streams, the desired water quality for recycling, and the concentration and disposal methods for residual solids.

- Water Treatment Processes: Greenfield projects offer the opportunity to incorporate advanced treatment processes in ZLD systems. Technologies like membrane filtration (ultrafiltration, nanofiltration, reverse osmosis) play a crucial role in achieving high-quality water recovery and separation of solids. These processes remove contaminants, including dissolved solids, suspended solids, and organic compounds, allowing for the production of treated water suitable for reuse.

- Evaporation and Crystallization: ZLD systems involve the concentration of wastewater through evaporation and crystallization processes. Greenfield projects enable the design and installation of efficient and optimized evaporation systems. Multiple-effect evaporators or mechanical vapor recompression (MVR) evaporators can be used to remove water from the concentrated wastewater stream, resulting in a concentrated brine solution. Crystallization processes can be employed to further separate and recover valuable salts or minerals from the concentrated brine.

- Solids Handling and Disposal: The remaining solids from the ZLD system, such as salts or minerals, need proper handling and disposal. Greenfield projects allow for the design and implementation of suitable dewatering and disposal methods for the concentrated solids. This may involve technologies like filter presses, centrifuges, or drying beds to remove water from the solids and render them suitable for disposal or beneficial reuse, such as in construction materials or land applications.

- Energy Efficiency and Sustainability: Greenfield projects in ZLD systems prioritize energy efficiency and sustainability. Through careful design and selection of equipment, energy-efficient components (e.g., high-efficiency pumps, motors, and compressors) can be incorporated. Integration of renewable energy sources, such as solar panels or waste heat recovery systems, can further enhance the sustainability of the ZLD system, reducing operational costs and environmental impact.

- Regulatory Compliance: Greenfield projects in ZLD systems must adhere to local, regional, and national regulations regarding water quality, discharge limits, and waste management. Compliance with these regulations ensures the proper treatment and disposal of wastewater, as well as the protection of the environment and public health.

Greenfield projects provide an excellent opportunity to design and implement efficient and sustainable ZLD systems. By integrating advanced treatment technologies, optimizing water recovery, and implementing effective solids handling and disposal methods, these projects contribute to minimizing water waste, conserving resources, and reducing the environmental impact of industrial or municipal wastewater streams.

FAQs: Greenfield projects, Water and Wastewater treatment plants

Q: What is a greenfield project?

A: A greenfield project refers to the construction and development of a new project on undeveloped land, typically with no existing infrastructure or facilities.

Q: What is a water treatment plant?

A: A water treatment plant is a facility that processes raw water from natural sources such as rivers, lakes, or groundwater, to make it suitable for human consumption or industrial use.

Q: What is a wastewater treatment plant?

A: A wastewater treatment plant is a facility that treats and processes wastewater from residential, commercial, and industrial sources to remove contaminants before it is discharged into the environment.

Q: Why are greenfield projects important for water and wastewater treatment plants?

A: Greenfield projects allow for the construction of new, modern treatment plants that can meet the increasing demand for clean water and effective wastewater management. They provide an opportunity to incorporate advanced technologies and design features for improved efficiency and environmental sustainability.

Q: What are the key considerations in the design of a greenfield water treatment plant?

A: A5: Some key considerations include the source of raw water, treatment processes required, treatment capacity, energy efficiency, compliance with regulations, and long-term operational costs.

Q: What are the key considerations in the design of a greenfield wastewater treatment plant?

A: Important considerations include the type and volume of wastewater, appropriate treatment processes (e.g., physical, biological, chemical), compliance with discharge standards, odor control, sludge management, and overall environmental impact.

Q: How long does it take to construct a greenfield water or wastewater treatment plant?

A: The construction timeline can vary depending on the scale and complexity of the project. It typically takes several months to a few years, considering factors like design, procurement, site preparation, and construction.

Q: What are some common challenges in greenfield water and wastewater treatment projects?

A: Common challenges include securing funding, acquiring suitable land, obtaining permits and regulatory approvals, managing community concerns, integrating new technologies, ensuring proper project management, and achieving long-term sustainability.

Q: How can greenfield projects contribute to environmental sustainability?

A: Greenfield projects offer an opportunity to incorporate environmentally friendly design principles, such as energy-efficient equipment, renewable energy sources, water conservation measures, and advanced treatment technologies, reducing the overall environmental impact.

Q: Are greenfield projects more cost-effective than upgrading existing treatment plants?

A: The cost-effectiveness of greenfield projects versus upgrades depends on various factors, including the condition and capacity of existing infrastructure, regulatory requirements, projected future demand, and available funding. A thorough cost-benefit analysis is necessary to determine the most economical option.

Q: How can community engagement be ensured during the development of greenfield projects?

A: Engaging with the local community is crucial for the success of greenfield projects. It involves holding public consultations, addressing concerns, providing transparent information, and involving stakeholders in the decision-making process. This helps build trust, gather valuable feedback, and ensure project acceptance.

Q: How can greenfield projects be funded?

A: Greenfield projects can be funded through a combination of public and private financing. Public funding sources may include government grants, loans, or subsidies, while private financing can involve investors, project developers, or public-private partnerships.

Q: How are greenfield projects regulated in terms of environmental compliance?

A: Greenfield projects must adhere to local, regional, and national environmental regulations. This typically involves obtaining permits and approvals related to water abstraction, discharge standards, environmental impact assessment, and other relevant regulations governing water and wastewater treatment.

Q: What are the potential long-term benefits of greenfield water and wastewater treatment plants?

A: Greenfield projects can provide long-term benefits such as improved water quality, enhanced public health, increased water availability, reduced pollution, economic growth through job creation, and the ability to meet future water demand.

Q: How can the success of a greenfield project be measured?

A: The success of a greenfield project can be measured through various metrics, including the project’s compliance with design specifications, meeting water quality standards, achieving environmental targets, operating within budget, and receiving positive feedback from the community and stakeholders. Regular monitoring and evaluation are essential to track performance and make necessary adjustments.