Silt Density Index in Waste Water Treatment

Silt Density Index Overview

The silt density index (SDI) is a measurement of the amount of suspended particles and colloidal particles in water. SDI is measured using the method ASTM D19.08 Standard Test for finding Silt Density Index (SDI) of Water, by consuming a 0.45 micron surface. SDI is extensively used for the selection and design of water treatment equipment, particularly membrane filtration systems, because it offers information regarding the fouling potential of the equipment. SDI is a simple and useful method that is widely used as a standard test to check the fouling potential for NF and RO membranes in pilot and large-scale treatment plants.

The fouling ability of suspended particles is measured by the SDI. Because the size and shape of the matter varies, it is not possible to measure the quantity of that matter. The quantity of suspended particles is measured by turbidity. They are not always the same and do not have a direct relationship. In practice, however, whenever the feed water seems to have a turbidity of less than 1 NTU, these membranes exhibit very little fouling. At a feeding SDI of less than 5, the membranes shows extremely little fouling.

The SDI test is being used to forecast particle fouling just on membrane surface and therefore avoid it. The Fouling Index (FI) and The Kolloid Index (KI) are two more names for it.

The SDI can help you figure out how much particle matter is in your water. The SDI is helpful in measuring the efficacy of various procedures for removing particulate matter, like as filtration or clarification. Because the SDI varies depending on the temperature of the water, results obtained at various temperatures may not even be comparable. The necessary SDI varies depending on the membrane filter manufacturer. As a result, SDI obtained values with filters created by various membrane manufacturers really aren’t comparable.

Recent improvements have also shown that measurement equipment, such as filtration assistance, can contribute to some variation in the ultimate SDI value. Nonetheless, from a practical standpoint, the SDI measurement is valuable. On a daily basis, water professionals use SDI measurements to guarantee that the pre-treatment filter solution is delivering high-quality, suitable liquid towards the reverse osmosis system. Discover regarding pre-treatment methods that have been proven to lower SDI levels in saltwater of varying quality.

History of Silt Density Index Testing

Early on in the construction of semi-permeable membrane processes for water processing, it was discovered that estimating the raw water’s membrane fouling capability was necessary to determine the requirement for pre-treatment. Membranes could cleanse tens of thousands of gallons of water before needing to be cleaned on certain water, whereas filtration of just few thousands of gallons clogged the membranes on others. Studies to link water’s fouling susceptibility to turbidity were only marginally successful. A test known as the silt density index testing (SDI test) has been designed to help correlate the amount of “silt” or solids in water with the likelihood of membrane fouling.

Principle of Silt Density Index Testing

The SDI test involves passing water through a 0.45-micron absolute filter membrane with a small diameter of 47 mm at a pressure of 30 psi. The time it takes to transit 500 mls at the ending of 5, 10, and 15 minutes is recorded and then used to estimate the SDI value without units.

Effects of Silt On Effluent Treatment

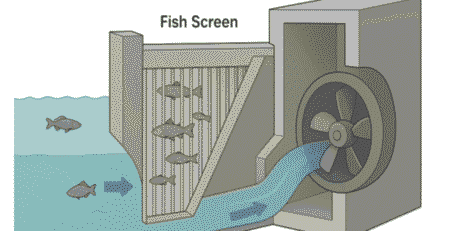

The existence of suspended solids inside the feed solution is one of the most difficult problems in reverse osmosis systems. While most systems have some form of disinfection, tiny particulates are to blame for clogging Reverse Osmosis Membranes. The silt density index is an indicator of water fouling potential in reverse osmosis systems.

Membrane fouling is indeed the primary factor of permeate flux degradation and quality of products degradation for reverse osmosis (RO) plants, hence fouling control is a major consideration in RO systems is presented. Scales, silt (specific), bacteria (bio fouling, bacterial proliferation), and organic fouling are the four main sources of fouling.

Fouling prevention entails pre-treating the supply water to reduce fouling and cleaning on a regular basis to remove any remaining fouling. The very first modules inside the plant are usually the most affected by fouling by particles (silt), microorganisms, and organics. Even though more concentrated feeding solutions induce more scaling, the final modules in the plant are the ones most affected, as they are subjected to some of the most saturated feed water.

In What Way SDI Is Diminished In Water?

Whenever the SDI is excessive, the water quality is poor. Media filtration is the most common method for decrease the quantity of silt in water. To entirely remove the undesired SDI from surface water with high silt content, pre-screening and much more complex water filtration methods are required.

For the filtering of organic compounds, sand medium filters are commonly used, with the particle size impacting the optimum degree of filtration. To reduce the requirement for continual backwashing, low media mass flow rate is used with sources of water containing and over 100 ppm of the suspended silts. Rinsing media filters is required when the pressure drops significantly and even when the central controller suggests it.

Ultrafiltration systems operate well in establishing a quite minimal SDI water solution before any more advanced wastewater treatment methods including such reverse osmosis pretreatment are used to remove it completely. Ultrafiltration uses integrated technology to cleanse low-quality feed water and effectively remove pollutants such as TDS, salts, hard substances, sand, and other contaminants. The life of the nano filtration and reverse osmosis membranes could be extended by using an ultrafiltration framework as a pre-treatment prior to actually nano filtration or reverse osmosis systems.

Process for Determination of SDI

The process of finding silt density index in waste water is following:

- The feed water must be provided at a pressure of 2 bars that will be controlled via a pressure regulator as well as a pressure gauge reading.

- The flow is turned on and off with its ball valve.

- The 0.45 m filter, which has a diameter of 47mm and is more capable of filling with colloidal material than that from hard particles including sand or scales, is housed in the filter flask.

- You can use this equipment to calculate the time it takes for 500 ml of feed solution to pass through the filter.

- Water continues to flow thru the filter at a pressure of 2 bars.

- You can check the time it takes for 500 ml to cross the filter after 5, 10, and 15 minutes. The 15-minute index is the smallest of the three that should be used to determine filter sizing.

- ASTM defines the 15-min SDI (SDI 15) as the required time for accurate and consistent testing. Although most people recommend measuring all three parameters, the 5- and 10 min SDI values are simply estimations of the 15-minute value.

Point of Consideration

Point of Consideration

These following points should be considered while silt density index testing:

- Performing the SDI testing at pressures else than 30 psi has no correction factor or correlation. The SDI value of 20 psi, on the other hand, should be acceptable. Plugging component at 30 psi is referred to as percent P30. It is calculated by multiplying the SDI by the test period [standard 15 minutes].

- The SDI can change depending on the temperature of the water; therefore readings obtained at various temperatures may not always be comparable! Throughout the test, the water temperature should stay consistent (1°C). This is required since the flow rate varies by around 3% per oC.

- The SDI will be different depending on the membrane filter vendor. SDI obtained results with filters from various membrane manufacturers cannot be compared because of this.

Calculation of Silt Density Index

SDI for water treatment is calculated by the following formula:

Here;

Here;

T = total test time (in minutes); it is usually 12=5, but it can be low in high SDI waters

Ti = initial time (in seconds) that will be required to collect 500 ml of sample

Tf = time (in seconds that is required to collect 500 ml of sample after 15 mins or less elapsed flow

Compatibility Values for SDI

The following suggest what the value of SDI means:

| SDI > 5 | water that requires additional purification |

| 3 | water needs to be completely examined |

| 1 | water of high grade |

| SDI < 1 | outstanding quality of water (UF/MF permeate) |

If silt density index is more than 5; this clearly means that the water needs more treatment and then we can further use it. If the value is 3 it means that the water needs to be completely examined. If the value is 1 it means that the water is of high grade and much better. If silt density index is less than 1 then the water is of outstanding quality.

Instruments for SDI Calculation

The silt density index (SDI) is calculated using the following instruments:

- Quick SDI – Automatic Instrument

The automatic instrument is made up of the following component:

- a (optional) feeding pump

- a container containing the entire measuring kit as well as an LCD monitor that displays the data

Simply place the filter disc in the device, attach it to a sample outlet, and push the power button. The instrument conducts all measurement cycles automatically and displays the SDI final outcome of the test.

- Easy SDI – Semi-Automatic Instrument

The semi-automatic device is made up of the following components:

- a feeding pump (if desired);

- a pressure regulator with a gauge;

- a housing for the filter

- polypropylene connector tubing

- The sample will be measured in a 0.5 liter container.

Simply place the filter disc in the instrument, attach it to a sample outlet, and push the start button. The client then must identify the two times with such a 15′ interval and use the above-mentioned formula to determine the SDI value.

Advantages

Producers in a wide range of industries, notably water filtering, reverse osmosis pre-treatment, and treatment of wastewater, benefit greatly from the existence of profit-making high heat filtered water and housing systems. These filters are designed to work better with larger filtration areas, lowering the cost of replacing filters, reducing environmental effect, and gradually making them the preferred filtration option.

Zero Liquid Discharge and Silt Density Index

A ZLD system’s main component may contain cross membrane operations (to retrieve water and concentrate the saline water), associated with thermal treatment. Ultrafiltration (UF)/RO twofold membrane procedures are designed to treat ZLD feed, with UF being used to reduce clarity and SDI. With the addition of an innovative feature, slightly elevated RO (HERO), a standard UF/RO twofold-membrane system may recover 60 to 75 percent of the effluent from the pre-treatment system, resulting in a total water recovery of > 90 to 95 percent. SDI plays important role in ZLD system and it used to measure sludge, heavy metals in waste water. SDI also used to calculate the units of turbidity and total suspended solids in zero liquid discharge waste water treatment

Effect of Chlorine on SDI and Ro Treatment

Because of the dispersed organic and biological particles that are the primary causes of pollution, chlorine treatment infusion has a distinct influence on the SDI value of water supply in the RO unit. The clarifier inside the pre-treatment system eliminated mineral contained colloidal particles in the unit under test with a municipal water source. The total abolition of water turbidity often does not imply the complete removal of the causes of high SDI levels. The addition of chlorine to units that use surface water has an influence on the biological causes of SDI, lowering the SDI value from the input to the RO. The correlations found for utilisation of RO production technologies with almost the same pre-processing systems and superficial feed water supply will help desalination units run more efficiently. Favourable SDI values of incoming water can be achieved by modifying the turbulence and ORP values in particular ranges. This is a major assistance in achieving ZLD

Waste Water Treatment Frequently Asked Questions

1) How is silt density index calculated?

To get the silt density index, divide the duration between tests by the result after multiplying the result by 100 and subtracting the value of the starting time over the final time from 1.

2) What does SDI stand for in water treatment?

The silt density index (SDI) calculates the concentration of colloids and suspended particles in water. A 0.45 micron membrane is used to measure SDI in accordance with ASTM D19.08, Standard Test Method for Silt Density Index (SDI) of Water.

3) How do you reduce SDI in water?

Media filtration is the main technique used to lessen the amount of silt in the water. Pre-screening and more sophisticated water filtration technologies are required for surface water that has a high silt concentration in order to entirely remove the undesirable SDI.

4) How do you measure SDI in water?

Measure the amount of time needed to collect 100 ml and 500 ml* from the moment the ball valve is fully opened. While keeping the valve open and allowing the flow to continue, note these times. 5. Repeat the time measurement needed to collect the 100 ml and 500 ml samples after 5 minutes have passed.

5) What does a density index indicate?

The density index can be used as a direct measurement for the melt water content because it shows how much lighter the sample that hardened in a vacuum is than the one that hardened under atmospheric pressure.

6) What is the formula of density index?

Explained: The density index is calculated by dividing the difference between the soil’s natural void ratio (e) and the soil’s maximum void ratio (emax) by the difference between the soil’s densest and loosest states. ID = “frac” (e max – e) (e max – e min).