What is Water Desalination?

Water desalination is a process that removes salts and mineral components from saline water. This is done by using the reverse osmosis and multi effect distillation techniques. It is important to note that water desalination is not a panacea, as some types of saline water will contain dissolved minerals. Despite this, there are many benefits to using water desalination, including a decrease in the need for bottled water, which saves money.

Why Reverse osmosis is Used for Water Desalination?

Reverse osmosis is a water desalination method where pressure is applied to a concentrated solution to achieve its desired concentration. A process of this type can be used for seawater desalination and wastewater reuse.

The process of reverse osmosis uses a high pressure pump to force water through a semi-permeable membrane. The permeability of the membrane decreases with the increasing pressure, which leads to a reduced concentration of salts in the water.

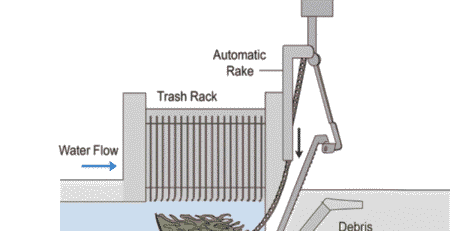

This decreases the efficiency of the reverse osmosis process. To counter this, a fouling control agent is introduced into the aqueous medium before contact with the RO membrane. It can prevent or control fouling by inorganic and organic foulants.

A fouling control agent is a synthetic substance formulated with a polysaccharide and an acidic polysaccharide. These two agents were found effective in controlling fouling of the reverse osmosis membrane.

In the present invention, a fouling control agent is provided that can be used to control fouling of the reverse osmosis and Na-softener membrane. Fouling on the membrane can result in plugging of the membrane and complete rejection of water.

The practice of the present invention can be implemented in a wide range of industrial applications. It can also be applied in hybrid systems to account for night-to-day and season-to-season fluctuations in demand.

This practice allows the consumer to gain affordable access to clean water. Using this technique, the concentrate produced by the reverse osmosis unit can be restored and reused in the regeneration of the Na-softener.

This technique is used to improve the value of salts in the concentrate. Alginic acid can be introduced into the aqueous medium to inhibit silica fouling on the reverse osmosis membrane.

What is Thermal Water Desalination?

Thermal water desalination is one of the most important processes for solving water scarcity in many parts of the world. It can be a good solution, but it can also be an expensive one. In order to produce more desalinated water, it will take more energy to evaporate the seawater. This can be accomplished with a number of techniques. For instance, the multi-effect distillation (MED) process is a thermal desalination process that uses thermal energy and reduces the boiling temperature of the brine.

Unlike other thermal methods, the multi-effect distillation process is a good option for reducing the environmental impact of the plant. However, it will require a large investment and generate more energy than the conventional process. Fortunately, a number of countries have taken up this method. Among them are the United States, Japan, Spain, and Gulf states. These countries have installed a total of 28 Mm3 of capacity at this time.

Another type of thermal desalination process is the multi-stage flash. This is the method used by the majority of global water desalination facilities. This technology is a good option for large-scale facilities, but can be costly to implement. Currently, the largest multi-stage flash plant in the world is located in the Gulf region, with a production capacity of 28.5 Mm3 per day. Despite the fact that the MSF process is a popular choice, its growth has been slow so far.

Pressure in Desalination Process

The desalination process involves the separation of salt from water by applying pressure. Desalination is used for the treatment of brackish and seawater.

It is a relatively new technology. Today’s typical brackish installations separate 98% of salt from feedwater. Typical brackish installations use pressures of 13.6 to 17 atm.

Water is pre-treated to remove suspended solids and increase the pH. Brine is then produced, which is a concentrated solution of salt. To dilute the brine, the treated effluent is added.

In the first stage, the feed is pumped through a reverse osmosis system. The pressure differential encourages the liquid flow through the membrane. For high-concentration waters, more pumping is required.

This stage is followed by aeration. The product water is then discharged to a storage cistern. Often, pH is adjusted and the resulting distilled water is sent back into the loop for the next cycle.

The return flow ratio is the percentage of previously used water discharged upstream as wastewater. High values indicate a higher dependence on treatment plants.

A novel biporous anisotropic membrane was developed that can desalinate water at ambient temperature. Unlike the standard membrane, this membrane is capable of operating at pressure.

To validate this model, a laboratory-made membrane was constructed for the study. Different feed inlet temperatures were used to test the performance of the membrane.

Based on the results of these significant studies, specific energy was calculated for a range of permeate fluxes. The lower the permeate flux, the lower the specific energy consumption.

Theoretical models were also developed to calculate the driving force. These models were then validated using a laboratory-made anisotropic super-hydrophobic membrane.

The model was also able to predict the evolution of the pressure over time. Results showed that the specific energy consumption of the desalination process was dependent on the pressure.

Multi-effect Distillation for Water Desalination

Multi-effect distillation (MED) for water desalination is a thermal process that utilizes a series of vessels to vaporize salt water. Each effect uses a lower temperature and pressure than the next effect. This allows for better control of scaling.

Multiple effect distillation is a very energy efficient distillation process. It is used for salt production and also for drinking water. The process has multiple effects that include up to twelve evaporation effects. Currently, the new MED designs have less volume, are cheaper to operate, and are more flexible.

The basic MED system is supplemented with a steam jet ejector, which allows the plant to take advantage of kinetic energy from the motive steam. Additionally, the design is more flexible and allows for a higher level of heat transfer.

These vapor compressors are powered by electrical or diesel engines, and improve the thermal performance of the MED unit. They also reclaim the unused energy that would otherwise be lost during the pumping and condensation processes.

A new solar polygeneration plant has been developed, which includes multi-effect distillation units and balance-of-plant devices. In addition, the plant uses a biomass auxiliary heater and a battery-powered absorption chiller.

Most industrial MED systems have a capacity range of 600 to 30,000 m3/day. These systems can be fueled by steam extracted from cogeneration boilers.

Medicinal applications have also been successfully carried out using the MED process. Researchers have shown that the use of hydrogels and gel-polymer materials can help to enhance the efficiency of a MED system. Hydrogels are hydrophilic and semi-conducting. Using hydrogels for treatment can reduce the cost of producing safe drinking water.

In Conclusion

Water desalination has been around for many years but new technologies have made the process more energy efficient. It is an important societal function, as 1.7 billion people around the world are without access to clean drinking water. With the population growing, there will be a continued need for fresh water, and thus the applications and installation of desalination plan is going to increase gradually to fulfil the need of drinkable water.