Usefulness of IoT and Artificial Intelligence in Managing and Controlling TAN (Total Acid Number) in Crude Oil Exploration

Usefulness of IoT and Artificial Intelligence in Managing and Controlling TAN (Total Acid Number) in Crude Oil Exploration

🔍 1. Understanding Total Acid Number (TAN) in Crude Oil

Total Acid Number (TAN) is a measurement of the acidity in crude oil. It represents the amount of acidic constituents, mainly naphthenic acids, expressed in milligrams of potassium hydroxide (KOH) required to neutralize one gram of crude oil.

✅ Why TAN Is Critical in Exploration and Production:

- High TAN Crudes (TAN > 0.5 mg KOH/g) are considered corrosive.

- Accelerates internal corrosion in well tubing, pipelines, heat exchangers, and storage tanks.

- Increases scaling, leading to pressure drops and inefficient flow.

- Affects emulsion stability, impacting separation efficiency.

- Leads to processing problems and higher maintenance costs in refineries.

TAN is a moving target—changing with reservoir fluid composition, temperature, production stage, and formation water intrusion.

🏭 2. Challenges in Monitoring and Controlling TAN in Crude Oil Operations

| Challenge | Impact |

| Manual sampling is slow and infrequent | Delayed response to rising TAN levels |

| Remote and unmanned sites | Difficult to deploy regular lab-based TAN measurement |

| Real-time risk of corrosion | Assets can be damaged before the issue is discovered |

| Variability in crude oil composition | Dynamic changes need dynamic control |

| Chemical overdosing | Increases cost, leads to environmental impact |

📡 3. IoT Solutions for Real-Time TAN Monitoring

IoT provides the infrastructure to digitally monitor TAN-related parameters in real time.

💡 3.1. Smart Field Instrumentation

| IoT Device | Function |

| Online TAN Analyzers | Measures TAN continuously using colorimetric titration or FTIR spectroscopy |

| Corrosion Probes (ER & LPR sensors) | Monitor corrosion rates in pipelines or tubing to infer TAN severity |

| Fluid Composition Analyzers | Identify naphthenic acid concentrations using spectroscopy |

| pH and Conductivity Sensors | Detect changes in water phase acidity |

| Multi-parameter Flow Meters | Provide context for TAN values with temperature, pressure, and flowrate |

These sensors are installed at:

- Wellhead and flowlines

- Separator inlets/outlets

- Pigging stations

- Storage tanks and crude gathering manifolds

🌐 3.2. Connectivity and Data Infrastructure

- Data Loggers and Gateways collect sensor data and transmit it via:

- Cellular (4G/5G)

- LPWAN (LoRaWAN, Sigfox)

- Satellite (for offshore or deep-remote sites)

- Data is pushed to cloud or edge AI platforms for analysis.

🔋 Power and Deployment

- Solar-powered sensor nodes enable deployment in unmanned and remote fields.

- Systems designed to operate in harsh conditions (IP68, explosion-proof, wide temperature range).

🧠 4. Role of Artificial Intelligence in TAN Management

IoT provides the raw data, but AI is the intelligence layer that makes sense of it and enables predictive and autonomous decision-making.

⚙️ 4.1. Virtual TAN Modeling

AI algorithms learn from historical lab-tested TAN data and correlate it with real-time sensor inputs such as:

- Flow rate

- API gravity

- Temperature

- Pressure

- Water cut

- Chlorides and H₂S levels

This model enables virtual estimation of TAN even when direct measurement is not feasible.

📈 4.2. Predictive Analytics

- Machine Learning (ML) models (e.g., regression trees, neural networks) predict future TAN trends based on production data.

- Early alerts are triggered before TAN levels reach critical thresholds.

🛑 4.3. Anomaly Detection

- AI detects sudden spikes or unusual TAN patterns that may indicate:

- Formation water breakthrough

- Equipment malfunction

- Sudden crude quality change due to intermixing reservoirs

🧪 4.4. Automated Inhibitor Dosing Control

- AI integrates with automated chemical injection systems.

- Dynamically adjusts corrosion inhibitor or neutralizing agent dosage based on:

- Current and predicted TAN values

- Flow conditions

- Corrosion rate feedback

This ensures:

- Optimal chemical usage

- Reduced cost

- Minimized environmental impact

- Protection against corrosion

🧾 4.5. Reporting and Compliance

- AI compiles compliance reports automatically for environmental and regulatory bodies.

- Dashboards and mobile apps provide insights for field engineers and control room operators.

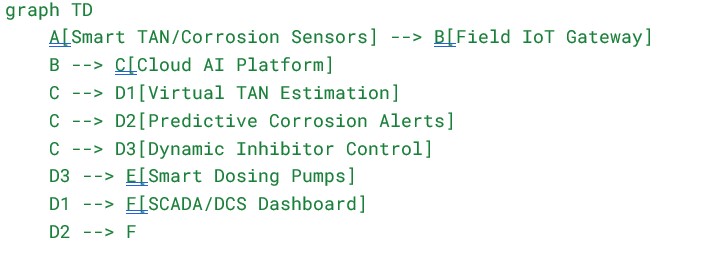

🧰 5. Example System Architecture

mermaid

CopyEdit

🏗️ 6. Field Application Examples

🛢️ Unmanned Onshore Oilfield

- Smart TAN sensors and corrosion probes connected to satellite-based IoT gateway

- AI model estimates TAN every 10 minutes and adjusts chemical dosing

- System detected a sudden rise in acid levels due to unexpected water influx and preemptively increased inhibitor injection

⚓ Offshore Platform

- Online TAN analyzer in test separator loop

- AI system mapped production zones and correlated high TAN episodes with certain well intervals

- Enabled targeted zone shut-in and blending to reduce TAN-related damage

✅ 7. Benefits of IoT + AI for TAN Control

| Benefit | Description |

| 🎯 Real-time Detection | Prevents corrosion before damage occurs |

| 🧠 Smart Decision-Making | AI learns patterns and optimizes responses |

| 💰 Reduced Chemical Use | Accurate dosing saves cost and prevents overdosing |

| 🔒 Operational Safety | Lower risk of pipeline leaks and equipment failure |

| 📊 Regulatory Compliance | Maintains accurate records and automated reports |

| 🛰️ Remote Autonomy | Ideal for unmanned and offshore platforms |

| 🛠️ Proactive Maintenance | Reduces emergency shutdowns and unscheduled repairs |

🔮 8. Future Developments

- AI + Digital Twin Integration: Simulate field chemistry, corrosion behavior, and inhibitor effects.

- Edge AI for Real-Time Control: Allow AI to make decisions locally without cloud dependence.

- Smart Blending Algorithms: Blend high TAN crudes with low TAN in real time using AI.

- AI-Driven Tank Farm Management: Control TAN during storage and export phases.

🏁 Conclusion

Managing TAN in crude oil exploration is no longer dependent on infrequent manual lab testing. By deploying IoT sensors and leveraging AI-based analytics, operators can:

- Track acidity levels continuously

- Predict corrosion risks early

- Automate chemical dosing

- Optimize production and asset longevity

This digital transformation is critical for safe, cost-effective, and environmentally compliant crude oil exploration—especially in unmanned or difficult-to-access locations.

“In the intelligent oilfield of the future, IoT will sense TAN, and AI will respond—instantly, autonomously, and accurately.”