Use of IoT and Artificial Intelligence (AI) in the mining industry for two critical areas

Use of IoT and Artificial Intelligence (AI) in the mining industry for two critical areas:

- Fleet Management & Optimization

- Video Surveillance & Security Monitoring

These technologies help mining companies increase operational efficiency, reduce costs, and enhance safety across their vehicle fleet and remote sites.

🚚 1. IoT & AI in Fleet Management & Optimization in Mining Industry

✅ Overview

Mining fleets consist of haul trucks, loaders, bulldozers, graders, water carts, light vehicles, and drills, which must be monitored, scheduled, and maintained effectively. IoT and AI provide real-time operational intelligence and predictive optimization of these mobile assets.

📡 A. IoT Contributions in Fleet Management

1. Vehicle Telemetry & Tracking

- GNSS (GPS + GLONASS) modules track real-time vehicle position, speed, heading, and route.

- Onboard telematics units collect data from engine control modules (via CAN bus):

- Fuel level

- Engine temperature

- Idling time

- Load per trip

- Brake status

2. Sensor Integration

- Load sensors measure the payload for each haul.

- Tire Pressure Monitoring Systems (TPMS) detect leaks or inflation issues.

- Fuel flow meters track actual consumption to identify theft or inefficiency.

3. Communication Networks

- Data transmitted via private LTE, satellite, or mesh networks in remote mines.

- Gateways or mobile edge devices pre-process telemetry data before sending to the cloud.

🤖 B. AI Contributions in Fleet Optimization

1. Route Optimization

- AI algorithms (Dijkstra, A*, genetic algorithms) find the shortest and most fuel-efficient haulage routes.

- Live road conditions, inclines, and congestion are factored in for real-time rerouting.

2. Cycle Time Optimization

- Machine learning models analyze loading → hauling → dumping → return

- AI identifies bottlenecks, underutilized trucks, or idle shovels to optimize match capacity.

3. Fuel Usage Prediction

- AI forecasts fuel usage per shift based on:

- Load size

- Route topography

- Operator behavior

- Helps identify excessive fuel usage due to aggressive driving or idling.

4. Predictive Maintenance of Fleet

- AI models trained on sensor and maintenance data forecast:

- Engine failures

- Transmission wear

- Brake system faults

- Automates work order generation in the CMMS.

🧠 C. Benefits of IoT + AI in Fleet Management

| Benefit Area | Improvement |

| Fuel Efficiency | 10–15% cost reduction |

| Fleet Utilization | +20% increase in productivity |

| Downtime | Reduced by 25–40% via predictive maintenance |

| Safety | Improved by route compliance & fatigue detection |

| Manual Intervention | Drastically reduced with automation |

📊 Fleet Management Architecture Diagram

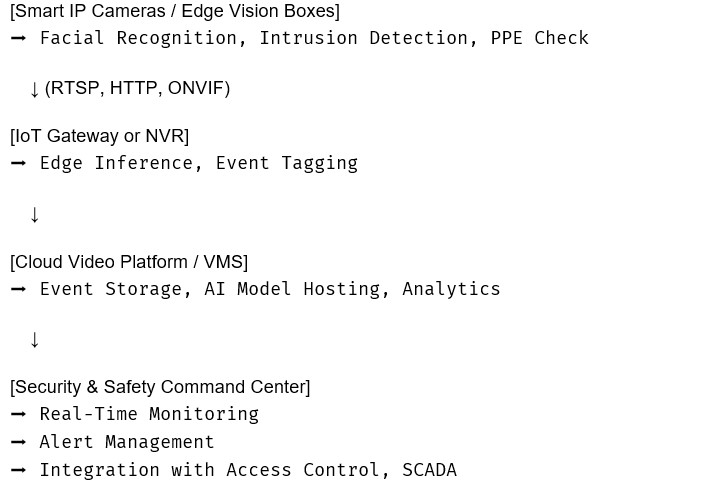

🎥 2. IoT & AI in Video Surveillance in Mining

✅ Overview

Mining sites require extensive 24/7 surveillance for worker safety, equipment security, environmental monitoring, and compliance. Traditional CCTV is passive. IoT-enabled smart video surveillance systems with AI computer vision are proactive and intelligent.

📡 A. IoT Contributions in Video Surveillance

1. Smart Cameras

- IP cameras with thermal, infrared, night vision, and pan-tilt-zoom (PTZ) capabilities.

- Connected via PoE, 4G/5G, or fiber optics to local NVRs or cloud storage.

2. Edge Video Processing

- Onboard processing in cameras or edge boxes runs basic analytics (motion detection, object counting).

- Reduces latency and bandwidth usage by processing footage locally before transmitting.

3. Environmental Integration

- Video feeds combined with IoT environmental data (e.g., gas leaks, temperature spikes, unauthorized access) to provide situational awareness.

🤖 B. AI Contributions in Video Surveillance

1. Intrusion Detection & Perimeter Security

- AI computer vision models (YOLOv7, OpenCV, DeepStream) detect:

- Unauthorized personnel in restricted zones

- Vehicle intrusions at odd hours

- Fence breaches or perimeter violations

2. PPE & Safety Compliance Monitoring

- CV models identify:

- Helmet use

- Reflective vests

- Safety boots

- Real-time alerts sent to supervisors if safety gear is missing.

3. Operator Behavior Monitoring

- Fatigue detection using facial landmarks (eye blinking, yawning).

- Detection of unsafe behaviors (phone use, smoking near flammable storage).

4. Fire, Smoke, and Spill Detection

- Thermal imaging + AI models identify:

- Spontaneous combustion

- Leaking tanks or chemical spills

- Automated escalation: sirens, SMS alerts, camera zoom on the hazard.

🧠 C. Benefits of Smart Surveillance

| Use Case | Benefit |

| Intrusion Detection | 24/7 real-time alerts, reduced security personnel |

| Safety Compliance | Continuous PPE monitoring, better incident control |

| Theft Prevention | Visual logs + automated response |

| Emergency Response | Faster detection of fire/gas leaks with location tagging |

| Data Storage | Reduced by filtering only relevant events |

📊 Smart Surveillance System Architecture

✅ Combined Applications: Fleet & Surveillance Synergy

- Cameras on trucks monitor loading activity, operator fatigue, and unsafe behavior.

- Video analytics cross-referenced with fuel consumption, trip logs, and geolocation to detect:

- Ghost trips

- Misuse of vehicles

- Material theft

🔄 Summary of Key Benefits

| Domain | IoT & AI Value |

| Fleet Efficiency | Optimized cycle times, fuel savings |

| Safety | PPE enforcement, route compliance |

| Asset Protection | Theft alerts, camera-based evidence |

| Environmental Monitoring | Visual confirmation of spills or damage |

| Labor Productivity | Reduced supervision effort |

| Cost Control | Less idling, lower maintenance, fewer incidents |