Use of Artificial Intelligence for Desalination Plants

Introduction

Water scarcity is a critical global challenge, with increasing populations, industrial demands, and climate change exacerbating the issue. Desalination—the process of removing salts and other impurities from seawater or brackish water—has emerged as a vital solution to address this scarcity, particularly in arid and semi-arid regions. However, desalination is an energy-intensive and complex process that requires careful management to ensure efficiency, sustainability, and economic viability.

Artificial Intelligence (AI) is transforming various industries by offering advanced data analytics, predictive capabilities, optimization, and intelligent automation. The integration of AI into desalination plants presents significant opportunities to improve operational efficiency, reduce energy consumption, extend equipment life, and ensure water quality. This paper explores in detail the applications, benefits, challenges, and future prospects of using AI in desalination plants.

1. Overview of Desalination Technologies

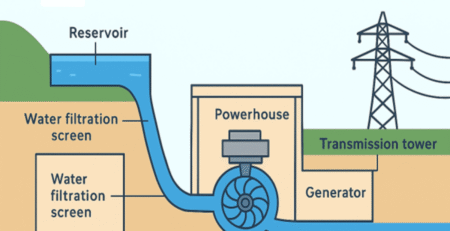

Desalination technologies can be broadly categorized into two main types:

1.1 Thermal Desalination

● Multi-Stage Flash (MSF)

● Multi-Effect Distillation (MED)

● Vapor Compression (VC)

These processes use heat to evaporate water and then condense it, leaving salts behind.

1.2 Membrane Desalination

● Reverse Osmosis (RO)

● Electrodialysis (ED)

● Nanofiltration (NF)

Reverse osmosis is the most widely used technique today due to its lower energy requirements compared to thermal methods. However, RO systems involve complex processes including high-pressure pumping, pre-treatment, and membrane maintenance.

2. Challenges in Desalination Operations

Desalination plants face numerous operational and environmental challenges:

2.1 High Energy Consumption

Desalination, particularly RO, is energy-intensive, contributing to high operational costs and carbon emissions.

2.2 Membrane Fouling and Scaling

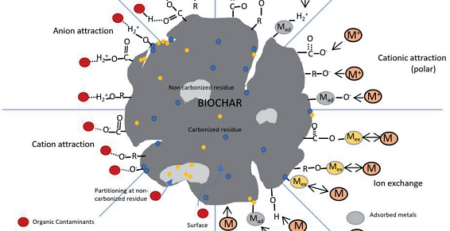

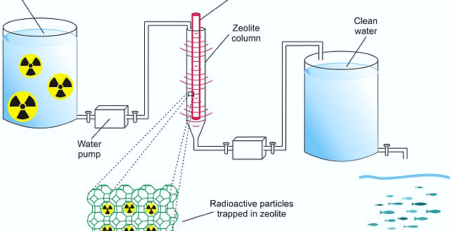

Membrane systems are susceptible to fouling by biological organisms, scaling due to salt precipitation, and clogging from particulates.

2.3 Process Optimization

Ensuring optimal settings for temperature, pressure, flow rates, and chemical dosing is complex and requires continuous monitoring.

2.4 Equipment Maintenance

Unexpected equipment failures can result in costly downtimes and water shortages.

2.5 Brine Disposal

Brine, a concentrated salt byproduct, must be managed responsibly to avoid environmental harm.

AI technologies can address these challenges through automation, predictive maintenance, real-time optimization, and intelligent decision support.

By integrating AI, WWTPs can analyze massive datasets from sensors, SCADA systems, and historical logs to identify patterns, predict failures, and automate decisions.

3. Role of AI in Desalination Plants

AI encompasses machine learning (ML), deep learning (DL), neural networks, natural language processing (NLP), and computer vision. These technologies can be applied across the entire lifecycle of desalination processes.

3.1 Process Modeling and Simulation

AI models can learn from historical operational data to simulate plant behavior under various scenarios. Unlike traditional mechanistic models, AI models can handle nonlinear, high-dimensional data without explicit physical equations.

● Artificial Neural Networks (ANNs): Useful for predicting product water quality, membrane fouling potential, and energy consumption.

● Support Vector Machines (SVMs): Can classify operational states and detect anomalies.

3.2 Predictive Maintenance

Using sensor data from pumps, valves, membranes, and other equipment, AI algorithms can predict failures before they occur. This reduces downtime, extends asset life, and minimizes repair costs.

● Example: Vibration analysis using ML to detect bearing wear in high-pressure pumps.

● Benefit: Enables condition-based maintenance instead of time-based maintenance.

3.3 Energy Optimization

AI can help in reducing specific energy consumption (kWh/m³) through optimal control of pumps, valves, and other energy-intensive components.

● Reinforcement Learning (RL): Can dynamically adjust operating parameters for minimal energy usage.

● Genetic Algorithms: Used for global optimization of operational setpoints.

3.4 Membrane Fouling Detection and Control

Fouling is a major cause of efficiency losses. AI can predict fouling trends and recommend pre-treatment adjustments or membrane cleaning schedules.

● Time-series analysis: Detects fouling from pressure drop or flow rate patterns.

● Computer vision: Monitors biofouling through image recognition.

3.5 Real-Time Monitoring and Quality Assurance

AI can integrate data from various sensors (pH, TDS, conductivity, turbidity) to monitor water quality continuously. Anomalies are flagged in real time.

● Digital twins: Virtual replicas of physical plants that simulate performance and recommend actions.

● NLP: Can analyze operator logs for trend recognition and process insights.

3.6 Chemical Dosing Optimization

Overdosing of anti-scalants, coagulants, or disinfectants leads to unnecessary costs and potential water quality issues. AI can optimize dosing based on actual water chemistry and flow conditions.

4. AI Techniques and Tools in Desalination

Various AI techniques are being applied or tested in desalination systems:

| Technique | Applications | Advantages |

|---|---|---|

| ANN (Artificial Neural Network) | Forecasting permeate flow, predicting fouling | Handles nonlinearities |

| SVM (Support Vector Machine) | Classification of failure modes | High accuracy in pattern recognition |

| Random Forest | Feature importance, fault detection | Robust to overfitting |

| K-Means Clustering | Anomaly detection, operational states | Unsupervised learning |

| Fuzzy Logic | Control systems, decision support | Handles uncertainty well |

| Reinforcement Learning | Adaptive process control | Self-learning optimization |

| Deep Learning (CNN, RNN) | Image analysis, time-series prediction | High accuracy, scalability |

6. Benefits of AI in Desalination

6.1 Operational Efficiency

AI enables plants to run closer to their design capacities without compromising safety or water quality.

6.2 Energy Savings

AI-driven optimization reduces energy input, which is the biggest cost in desalination.

6.3 Water Quality Assurance

Continuous monitoring and AI analysis ensure consistent water quality that meets regulatory standards.

6.4 Cost Reduction

From maintenance to chemical dosing, AI leads to substantial savings.

6.5 Sustainability

Lower energy use and better brine management support environmental goals.

7. Integration with IoT and Digital Twins

AI is most effective when integrated with the Internet of Things (IoT) and digital twin technology:

● IoT Devices: Provide real-time data from sensors across the plant.

● Edge Computing: Enables faster AI processing at the source.

● Digital Twins: Allow virtual experimentation and risk-free optimization.

Example: A digital twin of a desalination plant in Abu Dhabi simulates membrane fouling and optimizes cleaning cycles using real-time AI inputs.

8. Challenges and Limitations

8.1 Data Availability and Quality

AI requires large volumes of high-quality data. Sensor errors, missing data, and lack of historical records can hinder model performance.

8.2 Cybersecurity Risks

Integration with digital infrastructure increases vulnerability to cyber-attacks.

8.3 Lack of Skilled Workforce

Desalination engineers may lack training in AI, while data scientists may lack domain knowledge.

8.4 Model Interpretability

Black-box AI models can be difficult to interpret, leading to skepticism among operators.

8.5 Regulatory and Ethical Issues

Automated decisions may raise regulatory or ethical questions, especially around water safety.

9. Future Prospects

9.1 AI-Driven Autonomous Plants

Next-generation desalination plants may operate with minimal human intervention, using AI for all decision-making.

9.2 Federated Learning

Plants in different regions can collaboratively train AI models without sharing sensitive data.

9.3 Explainable AI (XAI)

Efforts to make AI decisions transparent and understandable will increase trust and adoption.

9.4 Integration with Renewable Energy

AI can help match desalination loads with intermittent renewable energy sources like solar and wind.

9.5 AI-Powered Brine Management

Innovative AI models can optimize brine disposal or reuse strategies, reducing environmental harm.

10. Recommendations for Implementation

1. Pilot Projects: Begin with pilot AI systems to validate benefits and address integration challenges.

2. Data Strategy: Invest in data infrastructure and establish data governance policies.

3. Training and Capacity Building: Equip plant staff with AI literacy and cross-disciplinary skills.

4. Collaborations: Partner with AI vendors, universities, and government agencies.

5. Security Protocols: Implement robust cybersecurity measures to protect digital assets.

6. Continuous Improvement: Regularly update models and incorporate feedback for improved performance.

Conclusion

Artificial Intelligence holds tremendous promise for enhancing the performance, sustainability, and cost-effectiveness of desalination plants. From optimizing energy consumption to ensuring water quality and predicting equipment failures, AI transforms traditional plant operations into intelligent, adaptive systems.

While challenges exist—ranging from data quality to cybersecurity and workforce readiness—the long-term benefits of AI adoption are significant. By strategically investing in AI capabilities, desalination operators can not only address current inefficiencies but also future-proof their operations in an era of increasing water scarcity.

Desalination is no longer just a matter of technology and energy; it is a data-driven science. With AI at the helm, the future of desalination is smarter, cleaner, and more sustainable.

Please contact us for AI hardware and total AI solutions for Desalination plants efficiency improvement with AI( ARTIFICIAL INTELLIGENCE)