Best Practices for Sludge Dewatering Equipment Maintenance and Troubleshooting

Sludge dewatering is a crucial process in wastewater treatment plants that involves removing moisture from sludge, making it easier to transport and dispose of. However, the process can be challenging and requires efficient maintenance to avoid downtime and costly repairs. In this article, we will explore the best practices for sludge dewatering equipment maintenance and troubleshooting.

Understanding the Basics of Sludge Dewatering Equipment

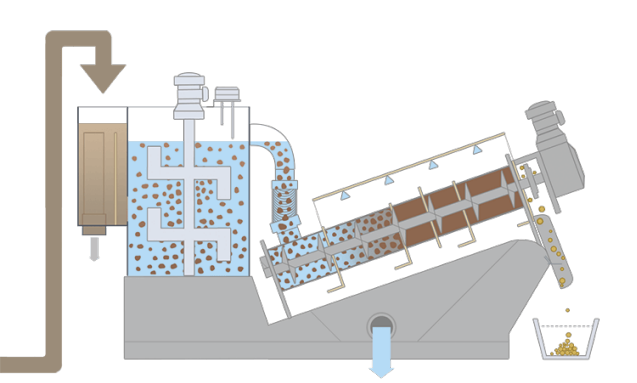

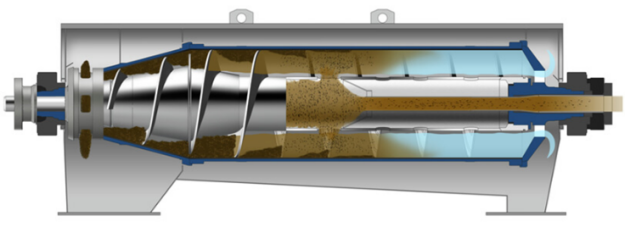

Before delving into the maintenance practices, it is crucial to understand the basic components of sludge dewatering equipment. Sludge dewatering equipment is designed to reduce the moisture content of sludge, making it easier to handle and dispose of. The most common types of equipment used in sludge dewatering are belt presses, centrifuges, and filter presses. These machines rely on different principles to dewater the sludge, and each requires specific maintenance practices.

Types of Sludge Dewatering Equipment

- Belt Presses

- Centrifuges

- Filter Presses

Best Practices for Sludge Dewatering Equipment Maintenance

Regular maintenance of sludge dewatering equipment is essential for maximizing uptime and prolonging the lifespan of the machines. Here are some best practices to follow:

Schedule Routine Maintenance Checks

Routine maintenance checks are essential to ensure the equipment operates at maximum efficiency. Schedule regular maintenance checks for all sludge dewatering equipment, and inspect all critical components, including the filter belts, bearings, motors, and pumps.

Keep Equipment Clean

Regular cleaning of equipment is necessary to prevent the buildup of sludge and other contaminants that can cause premature wear and tear. Use high-pressure water or steam to clean all components of the equipment thoroughly.

Lubricate All Moving Parts

Sludge dewatering equipment has several moving parts that require lubrication to prevent friction and wear. Use a high-quality lubricant to lubricate all moving parts, including bearings and gearboxes.

Monitor System Performance

Monitoring system performance is essential to detect potential issues early and prevent costly downtime. Install sensors to monitor the temperature, pressure, and other critical parameters of the system.

Train Staff

Train staff on proper equipment operation and maintenance to ensure the equipment is used correctly and that issues are detected early. Provide training on the different types of sludge dewatering equipment, how they work, and what to look out for when inspecting them.

Keep a Record of Maintenance and Repairs

Keeping a record of all maintenance and repairs is essential for tracking the performance of the equipment and identifying potential issues. Use a maintenance log to record all maintenance activities and repairs, including parts replaced and repairs made.

Troubleshooting Sludge Dewatering Equipment

Even with regular maintenance, sludge dewatering equipment may experience issues that require troubleshooting. Here are some common issues and how to troubleshoot them:

Belt Press Issues

Sludge leaks through the belt: Check the tension of the belt, and adjust as necessary. Ensure the belt is free of contaminants that can affect its performance.

Low cake solids: Check the polymer dosing rate, and adjust as necessary. Ensure the sludge feed rate is optimal.

Centrifuge Issues

Vibration or shaking: Check the balance of the centrifuge bowl, and adjust as necessary.

Low cake solids: Check the polymer dosing rate, and adjust as necessary. Ensure the sludge feed rate is optimal.

Filter Press Issues

Leaking plates: Check the condition of the filter plates, and replace as necessary. Ensure the filter cake is evenly distributed.

Low cake solids: Check the polymer dosing rate, and adjust as necessary. Ensure the sludge feed rate is optimal.