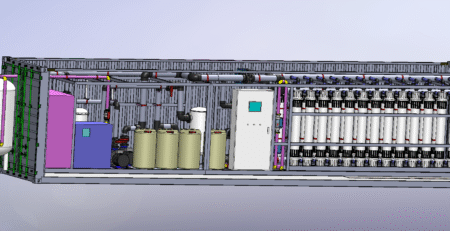

PFAS treatment plant for PFAS contaminated mining wastewater

Introduction:

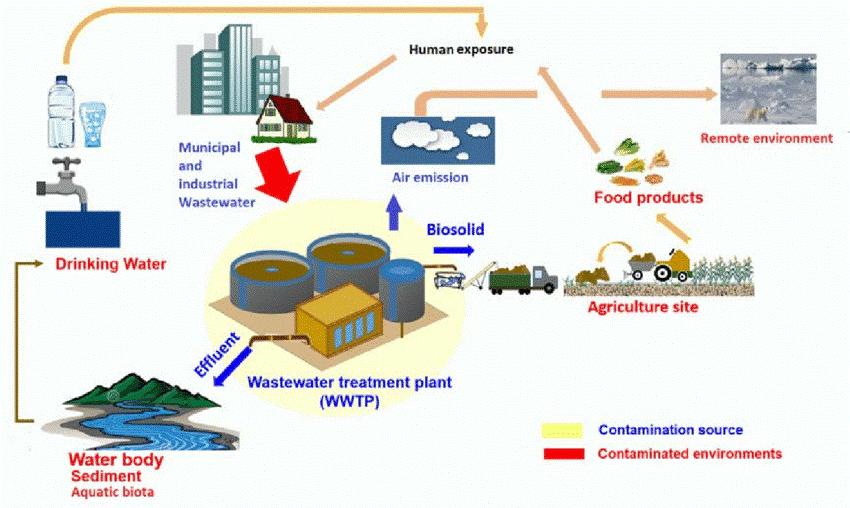

Due to the complicated structure of mining effluents and the persistence of per- and poly-fluoroalkyl substances (PFAS) in the environment, treating wastewater contaminated with these compounds from mining operations poses special problems. PFAS can enter mining wastewater from a number of different places, including processing chemicals, firefighting foams, and the leaching of minerals that contain PFAS. In order to reduce negative effects on the environment and preserve water supplies and local ecosystems, it is essential to build efficient PFAS treatment facilities for mining effluent.

PFAS in Mining Wastewater

Multiple paths can be utilized by mining operations to contribute to PFAS pollution in water:

- In order to put out fires and respond to emergencies, mining operations frequently employ firefighting foams that contain PFAS. The presence of PFAS in water sources can be caused by unintentional discharges or runoff from firefighting operations.

- Mineral processing may involve the use of chemicals containing PFAS at different stages. The process of mineral extraction and concentration can release these compounds into wastewater, which can contaminate it with PFAS.

- Pipes, hoses, and geotextiles are just a few examples of the mining equipment and materials that could contain PFAS. There is a risk that PFAS will end up in wastewater due to leaching from these products.

Challenges in PFAS Treatment for Mining Wastewater

- Complexity of Mining Effluents

Heavy metals, suspended particles, and a wide variety of chemicals utilized in mineral processing and extraction add to the complexity of mining wastewater, which already contains PFAS. It is necessary to take into account these co-existing contaminants when designing treatment plants for mining wastewater. - Variability in PFAS Composition

There is a great deal of variation in the PFAS composition of mining wastewater due to the fact that it is dependent on the particular operations, chemicals, and geological features of the mining site. The difficulty in creating treatment techniques that work for all PFAS chemicals stems from their inherent diversity. - Volume and Flow Rate

Wastewater from mining activities can be quite substantial and has a wide range of discharge rates. In order to consistently and efficiently remove PFAS, treatment plants need to be built to withstand these variations. - Site-Specific Challenges

The effectiveness of treatment systems can be impacted by the vastly different geographical and environmental circumstances found at different mining locations. How well PFAS removal procedures work could depend on things like temperature, pH, and whether or not other pollutants are present.

Treatment Technologies for PFAS-Contaminated Mining Wastewater

In order to treat mining effluent for PFAS, a number of different technologies are used. How the wastewater is treated, and its unique properties dictate which technology is best suited for the job. In order to effectively remove PFAS, it is common practice to use a mix of different procedures.

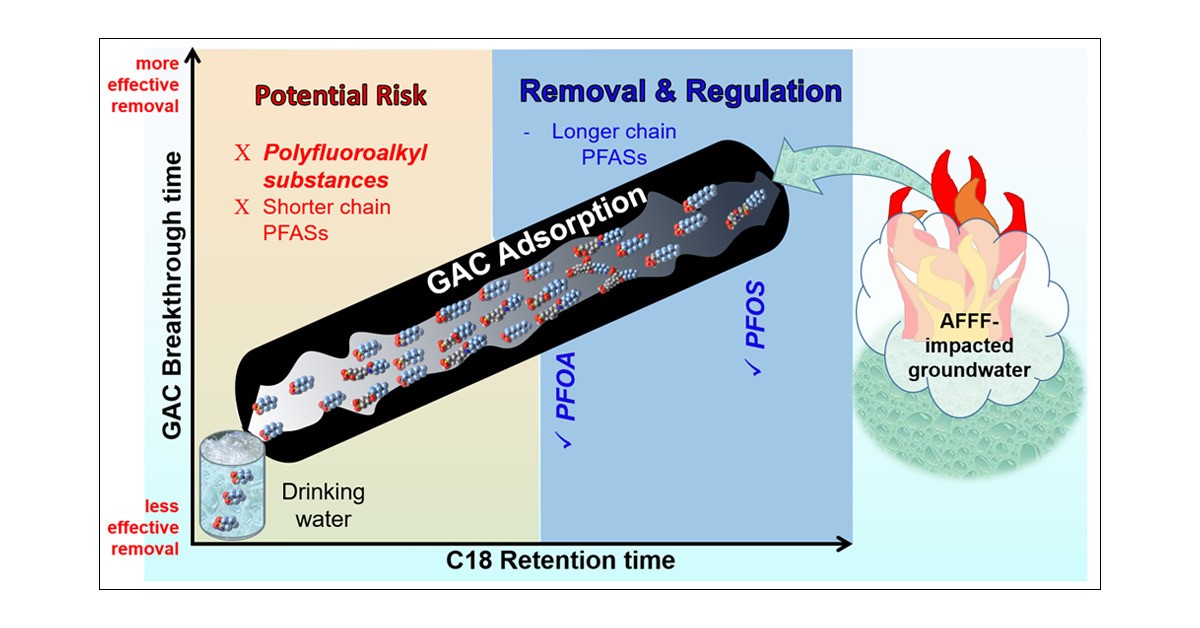

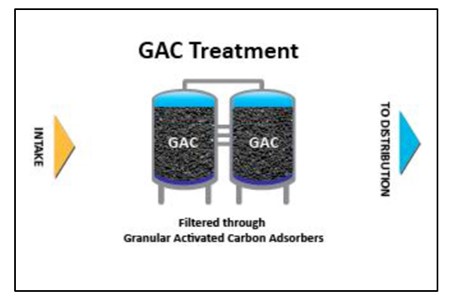

- Activated Carbon Filtration

One tried-and-true technique for removing PFAS from wastewater, particularly mining effluents, is activated carbon filtration. Activated carbon is able to efficiently absorb PFAS due to its high affinity for these compounds.Application

Granular activated carbon (GAC) and powdered activated carbon (PAC) are two options for PFAS treatment plants that deal with mining wastewater. While PAC can be added directly to the wastewater, GAC is more often found in fixed-bed filters.

Effectiveness

One of the most well-known methods for eliminating PFAS is activated carbon filtration. It works well with wastewater from mines that contain different amounts of PFAS and other pollutants. Nevertheless, because of its high concentration of PFAS, the discarded activated carbon requires cautious management.

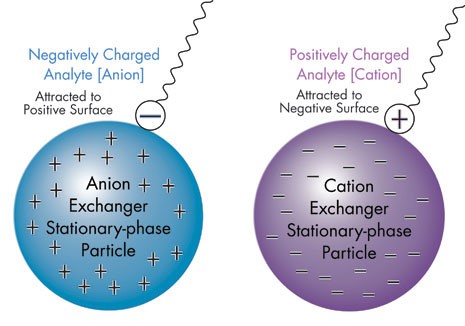

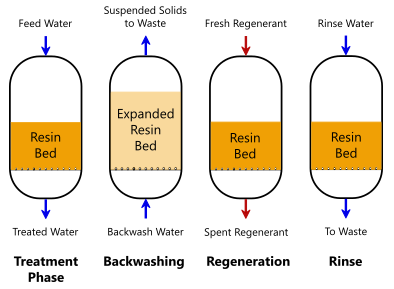

- Ion Exchange

One method for removing PFAS ions from wastewater is by ion exchange, which makes use of resins. When very specific removal of PFAS is needed, ion exchange can be a useful tool in the treatment of mining wastewater.

Application

The positively charged spots in ion exchange resins draw in and trap the negatively charged PFAS ions. Injecting a solution that dispenses and eliminates the trapped PFAS ions allows the resins to be renewed.

Effectiveness

One method that has proven to be quite effective in removing PFAS is ion exchange. Mining effluent with different compositions and amounts of PFAS can be treated with this method. Specific environmental factors should be considered while deciding the ion exchange resins and regeneration techniques to use.

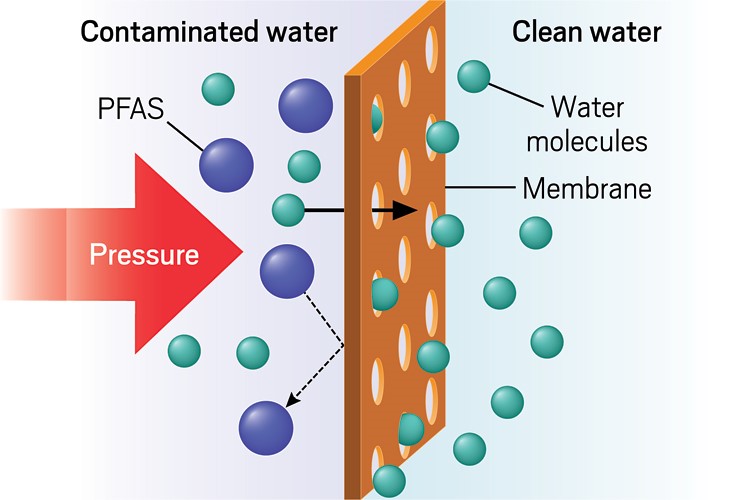

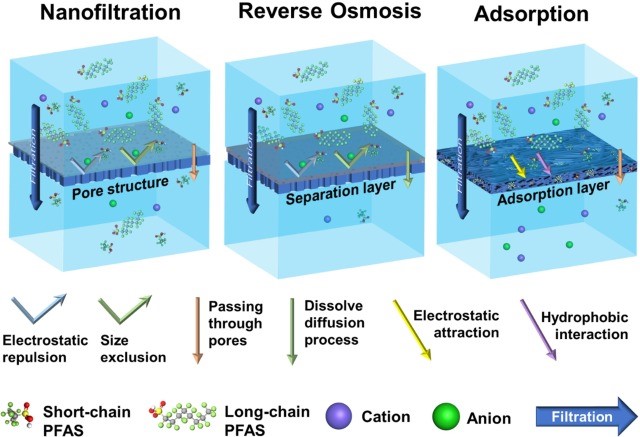

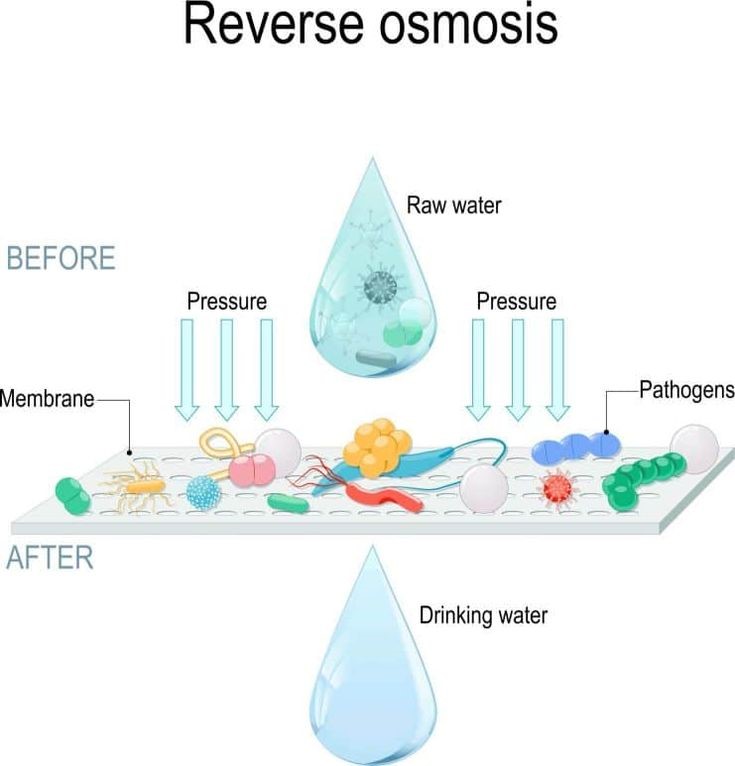

- Membrane Filtration (Reverse Osmosis and Nanofiltration)

Reverse osmosis (RO) and nanofiltration (NF) are two membrane filtration technologies that physically extract PFAS from water using semi-permeable membranes. Mining effluent can be effectively treated using these technologies.

Application

In order to selectively remove PFAS according to size and charge, RO and NF membranes can be used in mining wastewater treatment plants. Because of their adaptability, these procedures work well with high pressure and fluctuating flow rates.

Effectiveness

The remarkable efficacy of membrane filtration in removing PFAS is well-known. Specifically, RO has the ability to significantly lower PFAS concentrations. However, when considering these solutions for the long run, it is important to address factors like membrane fouling and operational costs.

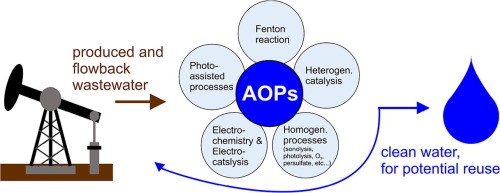

- 4. Advanced Oxidation Processes (AOPs)

Producing extremely reactive hydroxyl radicals is the key to Advanced Oxidation Processes (AOPs), which oxidise and decompose organic contaminants, such as PFAS, in wastewater. Potential AOPs for PFAS treatment include ozonation and UV/H2O2.

Application

By adding AOPs to mining effluent, chemical reactions can be set in motion that eventually degrade PFAS. When working with complicated PFAS combinations, these procedures shine.

Effectiveness

The breakdown of PFAS molecules into their component parts can be facilitated by AOPs. Their efficacy is conditional on variables like pH, reaction time, and the particular PFAS chemicals that are present. Treatment byproducts’ effects on the environment must be carefully considered, because AOPs might not mineralize PFAS entirely.

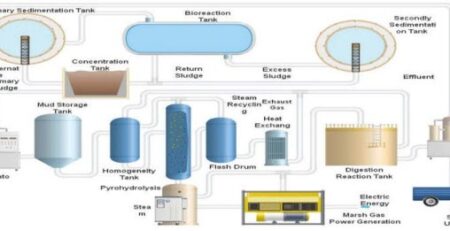

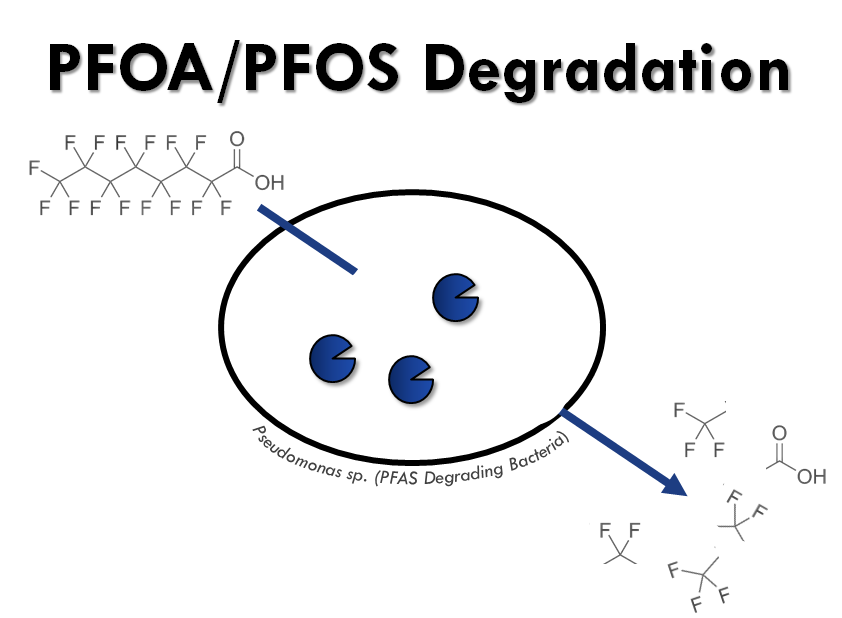

- Biological Treatment

In biological treatment, microorganisms are used to break down or change PFAS in wastewater. The development of biological therapy as a sustainable option for PFAS removal is still in its early stages, although it shows promise.Application

When it comes to removing PFAS, biological therapy is still in its infancy and has not seen extensive industrial use just yet. But as an environmentally friendly and long-term solution, it shows potential.

Effectiveness

Ongoing research is being conducted to determine the efficacy of biological therapy in PFAS elimination. Biochemical therapy efficacy is conditional on a number of variables, including the makeup of the microbial community, the surrounding environment, and the particular PFAS chemicals.

Considerations for PFAS Treatment Plants in Mining

- Site-Specific Assessment

The installation of PFAS treatment plants to treat mining wastewater must be preceded by an exhaustive site-specific evaluation. Finding possible causes of PFAS pollution requires analyzing the wastewater’s composition, learning about the surrounding geology and ecosystem, and so on. - Integration with Existing Infrastructure

The current mining wastewater treatment infrastructure should be easily integrated with PFAS treatment plants. Both the amount and velocity of the wastewater need to be thought of, in addition to any possible interactions with other treatment procedures. - Monitoring and Regular Testing

It is essential to regularly test the influent and effluent PFAS concentrations and monitor them continuously in order to evaluate the efficiency of treatment plants. The effectiveness of removal methods can be better understood with the use of real-time monitoring technology. - Management of Spent Materials

Active carbon, ion exchange resins, membrane filters, and other wasted materials need appropriate disposal management. Because of the high concentrations of PFAS in these products, their handling must adhere to regulations in order to avoid any negative effects on the environment. - Regulatory Compliance

It is critical to treat wastewater in accordance with regulatory guidelines for PFAS concentrations. It is imperative that treatment facilities adhere to the regulations and standards put out by the relevant authorities in both their design and operation. - Long-Term Sustainability

When thinking about sustainability in the long run, it’s important to weigh the pros and drawbacks of treatment technologies in terms of their operational costs and the effects on the environment. You should also make sure that the methods you choose can be used continuously and efficiently.

Case Studies

- Mining Site A

A PFAS treatment plant was set up at Mining Site A, a facility that focuses on mineral processing and extraction, to deal with the pollution of wastewater caused by firefighting foam and chemicals used in mineral processing. Complete elimination of PFAS is achieved by the treatment facility through the use of ion exchange and activated carbon filtration. In contrast to ion exchange resins, which selectively trap particular PFAS chemicals, activated carbon filters catch a wide variety of PFAS. Careful management of wasted materials and frequent monitoring of treatment efficiency ensure compliance with regulations.

- Mining Site B

Firefighting foam applications and mining materials leak into the wastewater at open-pit mining site B, contaminating it with PFAS. Here, biological therapy and membrane filtration (RO) work hand in hand. The biological treatment phase makes use of microbes that can degrade PFAS, and RO membranes efficiently remove PFAS according to size and charge. When these technologies are combined, they help to treat wastewater in a sustainable way while also addressing the issue of PFAS composition fluctuation.To address the environmental and health problems linked to PFAS pollution in mining operations, it is important to develop PFAS treatment plants for mining wastewater. Effective treatment solutions are difficult to design due to mining effluents’ complexity, PFAS composition variability, and the requirement to account for co-existing pollutants.

There is a wide range of technologies available for PFAS removal, including activated carbon filtration, ion exchange, membrane filtration, advanced oxidation processes, and new biological treatment methods. This diversity offers the opportunity to choose the technology that is most suited to the specific characteristics of mining wastewater. Implementing and operating PFAS treatment facilities at mining sites successfully requires case-specific assessments, integration with existing infrastructure, ongoing monitoring, and regulatory compliance.Research, industry involvement, and regulatory body collaboration are essential as our understanding of PFAS behavior in mining effluent changes and new technologies come out. Protecting water resources, ecosystems, and communities around mining operations is our top priority, therefore we’re working to find long-term, affordable, and ecologically friendly ways to handle PFAS.

Waterman Engineers Australia PFAS Treatment Plant Services

Being an engineering firm, Waterman is likely to provide services connected to PFAS treatment plants. This is particularly relevant given the growing worry over contamination of water sources with per- and poly-fluoroalkyl compounds (PFAS). Waterman Engineers of Australia may provide the following services for PFAS treatment plants:

- Site Assessment and Feasibility Studies

- Finding out how widespread PFAS contamination is requires comprehensive site surveys.

- Assessing the potential of PFAS treatment facilities according to site-specific feasibility assessments.

- Design and Engineering

- Client requirements and polluted water characteristics inform the design of PFAS treatment plants.

- Making use of technical knowledge to develop PFAS removal technologies that are both efficient and economical.

- Treatment Technologies

Activated carbon filtration, ion exchange, membrane filtration, advanced oxidation processes (AOPs), and maybe new biological treatment approaches are all part of a treatment plan that is designed to remove PFAS. - Regulatory Compliance

It is the responsibility of the Australian government to ensure that all PFAS treatment plants meet all applicable environmental standards and laws. - Monitoring and Testing

- Setting up systems to check the influent and effluent PFAS concentrations on a regular basis.

- Testing the water quality on a regular basis to make sure the treatment objectives are being fulfilled.

- Operational Support

- Supporting the day-to-day operations of PFAS treatment facilities to ensure their continued upkeep and effective operation.

- Making ensuring the treatment facilities are managed properly by providing training for plant operators.

- Spent Material Management

Thinking of ways to recycle or dispose of used materials like ion exchange resins and activated carbon in a reliable and legal way. - Collaboration and Stakeholder Engagement

- Working in tandem with pertinent parties, such as governing organisations, regulatory authorities, and communities at large.

- Having open and honest conversations to resolve issues and make sure PFAS management is thorough.

- Research and Innovation

Incorporating cutting-edge solutions into their offerings and remaining current on PFAS treatment technology developments. - Environmental Impact Assessment

Evaluate the possible effects on the environment of PFAS treatment methods and work to reduce their overall impact.

The Australian firm Waterman Engineers probably offers full-service design, construction, and management of PFAS treatment systems, as do many other environmental engineering companies. With a strong background in water and environmental engineering, they are able to provide clients with individualized solutions to protect water resources and ecosystems from PFAS contamination, assist them in meeting regulatory requirements, and handle contamination in general.

Visit their website or call their offices to get the latest and greatest information on Waterman’s PFAS treatment plant services. In reaction to new environmental concerns and technological developments, businesses in this sector frequently modify and broaden the range of services they offer.