Moving Bed Biofilm Reactor Technology for Waste Water Treatment

Overview

Moving bed biofilm bioreactor is a biological application that we use for the treatment of industrial waste water. In this mechanism we generally use biological method for the treatment and control of waste water. MBBR is a very productive biological remediation application that combines traditional sludge with biofilm substrate. The aeration tank and anoxic environment use in biochips. In Moving bed biofilm reactor, we uses floating Large Capacity Microorganism. The microorganisms in MBBR application utilize organic material. The media in MBBR also offer large area for biological process and let microorganisms to cultivate in tanks. The extensive surface area also reduces the impression of waste treatment tanks that require for industrial waste water treatment. The MBBR method can be aerobic or anaerobic, and it operates at a massive density.

What is MBBR?

What is MBBR?

Moving Bed Biofilm Reactor generally known as MBBR is a biological process that use operative biological technology to treat waste water that release from different waste streams. We generally use MBBR technology for treatment of water that released from community and industrial sector. In this process BOD, total nitrogen, and phosphorus are all removed from wastewater. MBBR technology is an effective system and cost effective so large number of people use this technology for waste water treatment system.

Role of Bacteria in MBBR

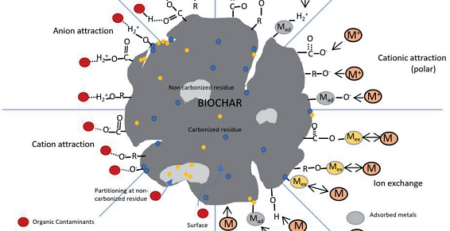

Biofilm culture present in Moving Bed biofilm reactor also give covered surface area for bacterial adjustment. Microorganisms that produce in this media helps in the decomposition of wastewater particles. The unwanted microorganism present in media is discharged with the treated water. MBBR technology are excellent for pre-treatment of organic-rich wastewater streams. The MBBR waste water system is an obvious solution to water problems. The MBBR technology are resistant to harmful seismic excitation. This technology is designed differently, cost-efficient, and ecologically beneficial. We design unique system for urban and industrial purposes.

Construction of MBBR Reactors

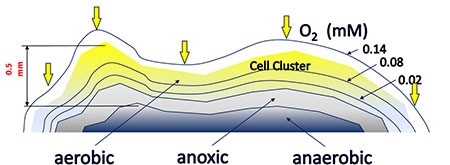

A container consists of an aeration system, biofilm carriers, and media retention screen comprise an MBBR. The provided processes air keeps the carriers medium moving, providing a wide protected surface area as a home for microbes, maintaining adequate nutrients delivery. The concentration of oxygen is also included into the structure. The needs of the aeration components become clear when combined with parameters such as the water level in the tank. Several aerators, from pipe impellers to membrane technology, give the ability to accurately modify the system attributes to the unique project needs, in addition to the suitable blowers or compressors type. The oxygen content is ideal for adjusting the blower output since it is reasonably straightforward to monitor using a sensor. In general, many operations may be implemented either automatically or manually, depending on the needs. This allows the plant’s functioning to be tailored to the demands of the owner.

Working of Moving Bed Biofilm Reactors

To maximize the amount of microbes for wastewater treatment. The MBBR method uses media within the bioreactor. Organic material present in waste water also consumed by the microbes present in MBBR tank. In the aeration basin, the medium offers large area for biological treatment of waste water. Microorganisms in this method cling and grow. Bubble from the aerator, which provides oxygen at the bottom of the very first chamber of the aeration basin, and also continuously agitate the material. Furthermore, the active surface area of MBBR medium is about 4000 m2/m3, and that is up to 6 times more than any other media on the market at the moment. The MBBR is a total blend, continuously run through system based mostly on biofilms concept that uses a combination of both sludge and traditional fixed film systems without the drawbacks.

Performance of MBBR

Performance of MBBR

The MBBR contain Biochip30 is an efficient MBBR media with a covered effective surface area about 5,500 m2/m3 for incapacitating microorganisms responsible for various biological water purification processes. This large area has already been experimentally verified and compares to competitive solutions that offer a range of 350 and 800 m2/m3. Its use is marked by exceptionally high removal rates and continuous systematic basis. The Removal rate of Biochips are 10 times more than traditional media carriers (all are different forms). This is performed via a greater porous system

Physical characteristic Biochip30 in MBBR

There are no pcbs or other solvents in the MBBR Biochip30 medium. Biochip does not contain bisphenol or other aromatic chemicals. It’s composed of polyethylene, artificial stabilizers, and minute quantities of mono-ester of glyceric acid, vinegar, and soda. When utilized these applications that are delicate to dangerous substances, including aquaculture. The manufacturing process becomes crucial. Bisphenol A and phthalates have been linked to cancer and hormone disruption. Biochip 30 has parabolic shape that provides uniform mixing of chip in the tank. The maximum retention of the dynamic biofilm inside the flow of water. The microbes have access to substrate and oxygen at all times and under any load state as a result of flow.

Application of MBBR

MBBR can be used to industrial effluents of various qualities. Its application is guided by the intended outcomes and state discharge laws. It is use for

- Biological oxygen demand removal

- Nitrification

- Denitrification

Generally, MBBR technology used for treatment of industrial effluents and municipal waste water

Advantages of MBBR Technology

- The MBBR wastewater treatment provides successful outcome while utilising minimal energy.

- Organic compounds, nitrification, and denitrification are separated using this process.

- It helps conserve water.

- It’s simple to keep up with.

- Is ideal for a large amount of organic content.

- Toxic stress has no effect on it.

- Because of the high efficiency of the sludge retention period, the nitrification process is improved (SRT).

- Sludge formation dropped.

- The sludge should not need to be recycled.

Conclusion

Furthermore, MBBR system is effective for treating wastewater since it is versatile in application and can be moved simply. Finally, MBR is environmentally friendly. It is ideal for high loads and easy to operate and also reduce energy cost and have dense footsteps. The MBBR system have flexible design due to this it require least operation care and maintenance.

Moving Bed Biofilm Reactor Frequently Asked Questions

1) What is the purpose of moving bed biofilm reactor?

While reducing the size of new plant deployments, these methods dramatically raise the capacity and efficiency of wastewater treatment facilities that are already in operation. With this technique, it is feasible to dispose of waste effectively while using little energy.

2) What is the MBBR technology?

Prof. Hallvard degaard at the Norwegian University of Science and Technology first developed the moving bed biofilm reactor (MBBR), a kind of wastewater treatment method, in the late 1980s. It was made available for sale by Kaldnes Miljöteknologi (now called AnoxKaldnes and owned by Veolia Water Technologies).

3) How biofilms are used in wastewater treatment?

The organic matter and nutrients in the wastewater are assimilated by a living biomass (biofilm) that is adhered to the discs. Any extra biomass that shears off the discs as a result of the rotation of the discs and the force of gravity is subsequently removed from clear water using a standard clarifying procedure.

4) What are the steps to biofilm formation?

The five stages of biofilm development are as follows: stage 1 is initial attachment; stage 2 is irreversible attachment; stage 3 is maturation I; stage 4 is maturation II; and stage 5 is dispersion.

5) What are the characteristics of biofilm?

The nature of the bacteria, the host, and the surface characteristics of the substance are three crucial variables that affect biofilm formation.