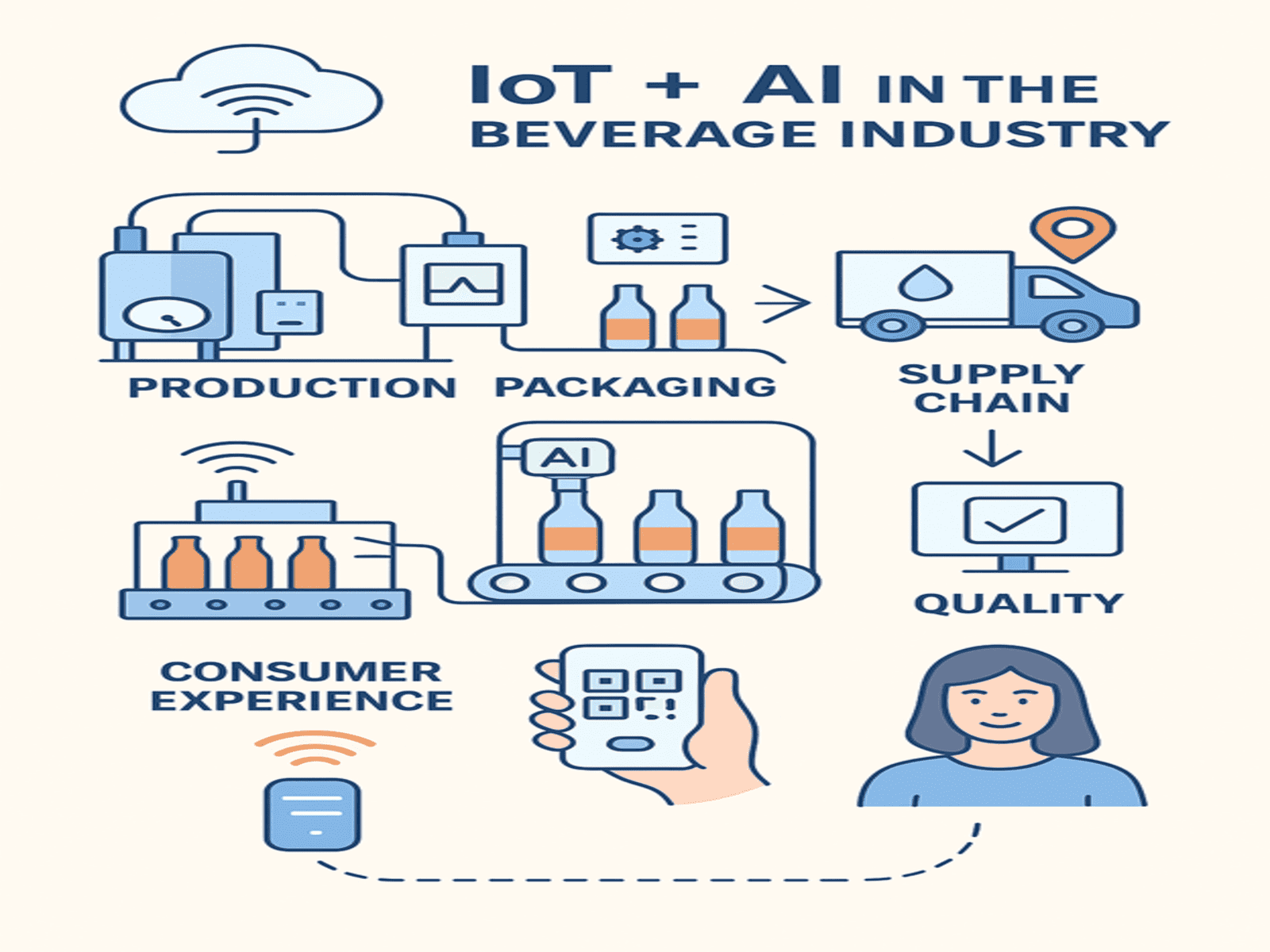

IoT and AI in the Beverage Industry

1. Introduction

The beverage industry faces challenges such as high competition, strict quality standards, variable raw material quality, sustainability pressures, and supply chain complexity. IoT and AI offer real-time data collection, predictive insights, and automation to ensure consistency, reduce costs, and meet consumer demands.

2. Role of IoT in the Beverage Industry

IoT integrates physical equipment, sensors, and networks to capture and transmit real-time data across the value chain:

- Smart Production Monitoring

- IoT sensors track temperature, pH, sugar content, and carbonation levels in brewing, fermentation, and bottling processes.

- Ensures consistency in taste and quality.

- Energy & Water Optimization

- Flow meters and IoT devices monitor water and steam usage in cleaning-in-place (CIP) systems.

- Helps reduce resource waste and achieve sustainability goals.

- Packaging & Bottling Line Monitoring

- IoT cameras and sensors detect defects in bottles, cans, or labels.

- Prevents defective packaging from reaching customers.

- Cold Chain Monitoring

- IoT sensors with GPS track temperature and humidity during beverage transport (especially for dairy, beer, and juices).

- Ensures freshness and regulatory compliance.

- Consumer Interaction

- Smart packaging (QR codes, NFC tags) allows consumers to trace the origin and authenticity of their beverage.

3. Role of AI in the Beverage Industry

AI uses IoT-generated data to predict, analyze, and optimize manufacturing and business processes:

- Predictive Maintenance

- AI algorithms analyze machine vibration, temperature, and motor data to predict equipment failure (bottling lines, mixers, chillers).

- Minimizes downtime and improves reliability.

- Process Optimization

- AI models adjust brewing, blending, and carbonation parameters in real time to optimize flavor, reduce waste, and maintain consistency.

- Quality Control with Computer Vision

- AI-powered cameras inspect color, clarity, and foam stability of beverages.

- Detects packaging mislabels, leaks, or contamination.

- Supply Chain & Demand Forecasting

- AI predicts demand based on historical sales, seasonality, and external factors (weather, festivals, sporting events).

- Helps optimize production schedules and inventory.

- Personalized Products

- AI analyzes consumer preferences (via apps, e-commerce, loyalty programs) to guide R&D for new flavors or customized beverages.

4. Benefits of IoT + AI Integration in Beverages

- Consistency in Taste & Quality – Automated monitoring prevents variation in batches.

- Regulatory Compliance – Digital traceability ensures adherence to food safety standards (FDA, HACCP, ISO).

- Resource Efficiency – Reduces water, energy, and raw material waste.

- Cost Reduction – Predictive maintenance and smart scheduling lower operational expenses.

- Enhanced Customer Trust – Transparent traceability builds consumer confidence.

- Market Agility – Fast adaptation to consumer trends with data-driven insights.

5. Example Use Case

- A smart brewery uses IoT sensors to track fermentation temperature and pH.

- AI analyzes the data to optimize brewing time and prevent spoilage.

- Automated bottling lines use computer vision for label accuracy.

- Finished products are tracked through IoT-enabled logistics, maintaining freshness until delivery.

6. Future Outlook

- Digital Twins of Beverage Plants – AI simulations to optimize production without halting operations.

- Blockchain + IoT – Transparent supply chain for premium beverages (wine, craft beer).

- AI-powered Product Innovation – AI analyzing social media and sales data to design new flavors.

- Sustainability Tracking – IoT & AI will help achieve net-zero water and energy goals in beverage plants.

✨ In short:

- IoT is the “sensing layer” that monitors every drop, bottle, and batch.

- AI is the “decision-making layer” that ensures efficiency, quality, and innovation.