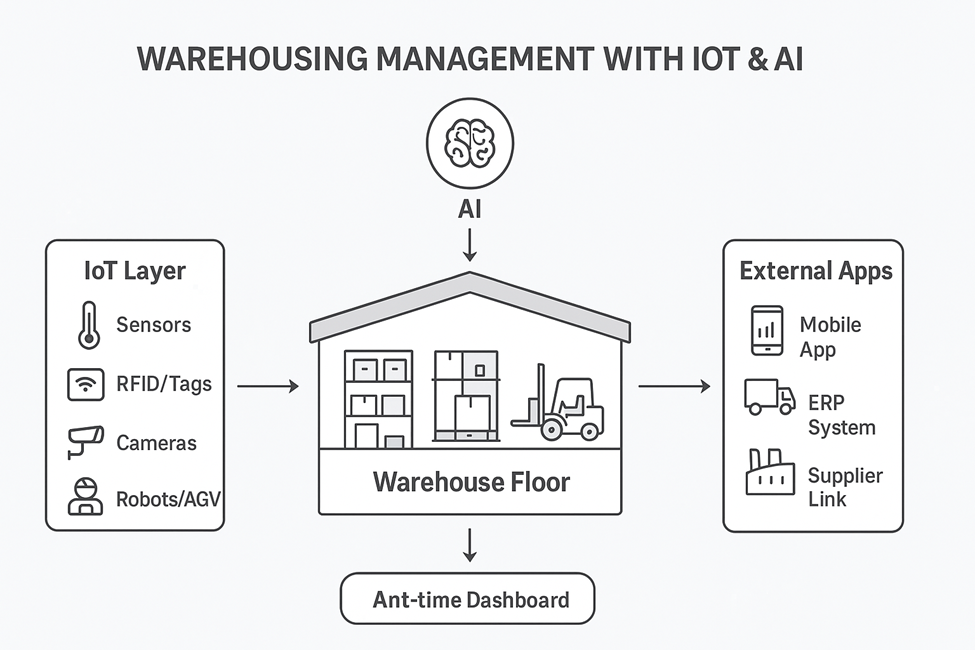

IoT & AI in Warehousing Management

1. Introduction

Traditional warehouses rely heavily on manual processes, making them prone to errors, delays, and inefficiencies. With IoT sensors and AI-driven analytics, warehouses can achieve real-time visibility, automation, and predictive intelligence.

2. Applications of IoT in Warehousing

IoT enables connectivity, monitoring, and control inside warehouses.

- Real-Time Inventory Tracking

- RFID tags, smart shelves, and barcode scanners update stock levels automatically.

- Prevents stockouts and overstocking.

- Environmental Monitoring

- IoT sensors measure temperature, humidity, vibration, and light.

- Crucial for pharmaceuticals, food, and chemicals that need strict storage conditions.

- Automated Equipment Monitoring

- Sensors on forklifts, conveyors, and robots track usage, fuel, and wear & tear.

- Enables predictive maintenance.

- Warehouse Security

- IoT-enabled cameras, motion sensors, and smart locks ensure asset protection.

- Alerts for unauthorized access or tampering.

- Energy Management

- Smart meters and IoT sensors optimize lighting, cooling, and HVAC systems.

- Reduces energy costs.

3. Applications of AI in Warehousing

AI processes IoT-generated data and provides automation, prediction, and optimization.

- Automated Picking & Packing

- AI-driven robots use computer vision to pick items with accuracy.

- Reduces human errors and speeds up order fulfillment.

- Demand Forecasting

- AI analyzes sales data, trends, and seasonal demand.

- Ensures optimal stock levels in the warehouse.

- Intelligent Route Planning (Inside Warehouse)

- AI optimizes routes for robots and workers.

- Reduces travel time in large warehouses.

- Predictive Maintenance

- AI predicts when equipment will fail.

- Prevents downtime in critical warehouse machinery.

- Labor Optimization

- AI schedules workforce shifts based on demand, peak times, and workload.

- Increases productivity and reduces overtime costs.

4. Combined Benefits of IoT + AI in Warehousing

- End-to-End Visibility – Track goods from arrival to dispatch in real-time.

- Reduced Costs – Less waste, energy use, and equipment downtime.

- Faster Operations – AI-powered robots + IoT tracking speeds up processes.

- Higher Accuracy – Reduced inventory errors and misplacements.

- Customer Satisfaction – Faster and more reliable order fulfillment.

5. Future of Smart Warehousing

- Autonomous Warehouses – Fully automated warehouses with IoT-driven robots and AI scheduling.

- Digital Twins – Virtual replicas of warehouses for simulation and optimization.

- Drone Inventory Checks – IoT-enabled drones scanning shelves with AI vision.

- Blockchain + IoT – Ensuring transparency and traceability of warehouse data.

✨ In summary:

- IoT provides data collection and real-time monitoring.

- AI provides decision-making, prediction, and automation.Together, they make warehouses smarter, leaner, and customer-centric.