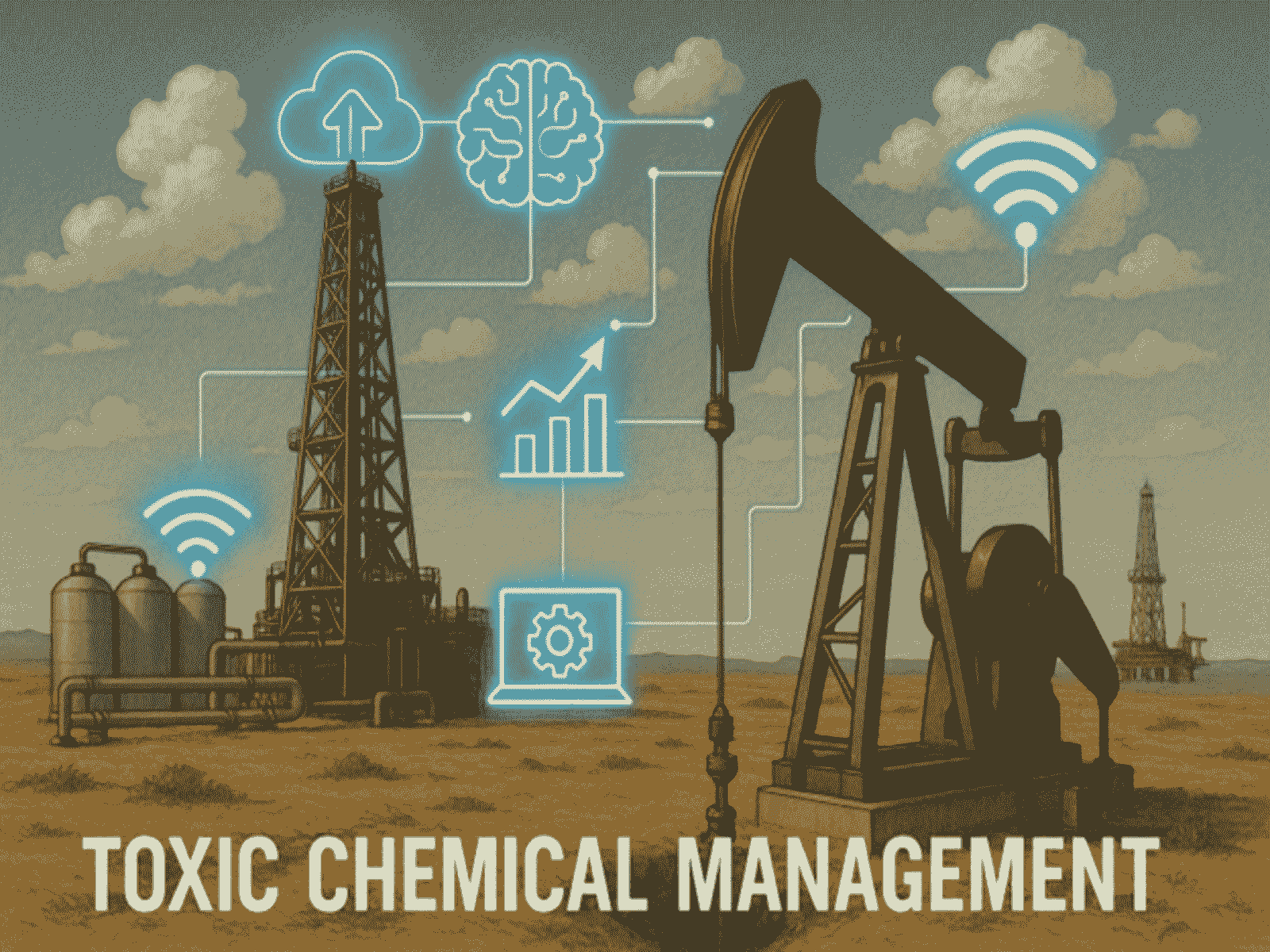

Detection and Control of Toxic Chemicals and Gases During Gas Exploration Using IoT and Artificial Intelligence

Detection and Control of Toxic Chemicals and Gases During Gas Exploration Using IoT and Artificial Intelligence

1. Introduction

Gas exploration activities pose significant safety and environmental risks due to the potential release of toxic chemicals and hazardous gases such as hydrogen sulfide (H₂S), carbon monoxide (CO), volatile organic compounds (VOCs), and other toxic hydrocarbons. Rapid detection and effective control of these substances are critical to safeguarding personnel, equipment, and the environment.

The integration of Internet of Things (IoT) sensors with Artificial Intelligence (AI) analytics offers a cutting-edge solution for real-time monitoring, early detection, and automated response to toxic gas hazards in gas exploration sites, especially in unmanned wells and remote locations.

2. IoT-Based Detection of Toxic Chemicals and Gases

IoT sensor networks form the foundational layer by continuously monitoring air quality and gas concentrations across the exploration site:

- Gas Sensors and Detectors:

- Electrochemical sensors for H₂S, CO, NOx, SO₂

- Infrared sensors for methane and VOCs

- Photoionization detectors (PIDs) for volatile organic compounds

- Catalytic bead sensors for combustible gases

- Environmental Sensors:

- Temperature, humidity, and wind speed sensors that affect gas dispersion

- Pressure sensors to monitor wellhead and pipeline conditions

- Wireless Communication:

- Sensor data transmitted via LPWAN (LoRaWAN, NB-IoT), cellular, satellite, or mesh networks

- Enables continuous remote monitoring and data aggregation in cloud or edge computing platforms

3. Artificial Intelligence for Toxic Gas Detection and Control

AI transforms raw sensor data into actionable intelligence through:

3.1 Real-Time Hazard Identification

- Machine learning algorithms analyze sensor inputs to detect abnormal increases in toxic gas concentrations beyond safety thresholds.

- AI models consider environmental factors and sensor fusion data to reduce false alarms and improve detection accuracy.

3.2 Predictive Risk Assessment

- AI forecasts potential leak or toxic gas release events by analyzing patterns, historical incidents, and operational parameters.

- Enables proactive intervention before hazardous levels develop.

3.3 Automated Control and Mitigation

- Upon detection, AI systems can trigger:

- Automated ventilation systems to disperse gases

- Remote valve shutdowns to isolate affected sections

- Activation of scrubbers or chemical neutralizers

- Emergency alarm and evacuation notifications to personnel and control centers

3.4 Incident Analysis and Continuous Improvement

- AI platforms log all detection and control events for post-incident analysis.

- Models are continuously refined using new data to enhance future detection and response effectiveness.

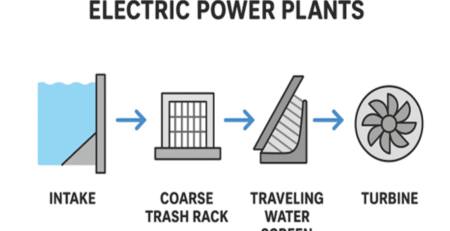

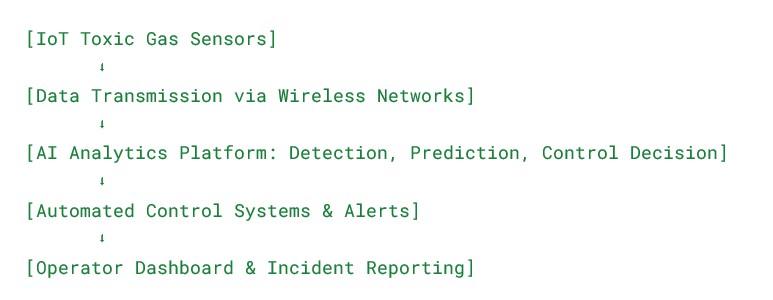

4. Implementation Workflow

text

CopyEdit

5. Benefits of IoT and AI in Toxic Gas Management

| Benefit | Description |

| Early Detection | Real-time monitoring ensures immediate hazard identification |

| Accurate Alerts | AI reduces false alarms by contextual data analysis |

| Automated Safety Actions | Rapid activation of controls reduces human response time |

| Remote Monitoring | Enables safe supervision of unmanned or hazardous sites |

| Regulatory Compliance | Automated records support environmental and safety audits |

| Improved Worker Safety | Minimizes exposure to toxic gases through timely warnings |

6. Use Case Example: H₂S Monitoring in Unmanned Gas Well

- Setup: Multiple electrochemical H₂S sensors deployed around the wellhead and nearby ventilation points.

- Process: Sensor data streamed to a cloud-based AI platform that continuously monitors concentration trends.

- Action: AI detects a sudden rise in H₂S levels, predicts gas dispersion path using wind data, and commands automated shutoff valves while triggering alarms to remote operators.

- Outcome: Immediate containment prevents worker exposure and environmental contamination.

7. Conclusion

The combination of IoT and Artificial Intelligence offers an intelligent, reliable, and efficient system for the detection and control of toxic chemicals and gases during gas exploration. This integration ensures enhanced safety, operational continuity, and regulatory compliance, particularly in unmanned or hard-to-access sites.