Auto Trash Rakes in Hydroelectric Power Plants

Auto Trash Rakes (Automatic Trash Raking Systems) for hydroelectric power plants. These are essential for maintaining clean water flow to turbines.

🔹 Auto Trash Rakes in Hydroelectric Power Plants

1. Introduction

Hydropower stations draw water through intake structures. The first protective barrier is the trash rack, which blocks large debris such as logs, branches, plastics, ice, aquatic vegetation.

Over time, these racks get clogged, increasing head loss (resistance to water flow), which:

- Reduces turbine efficiency

- Causes cavitation and damage

- Raises maintenance costs

Traditionally, operators cleaned racks manually using hooks or cranes. Today, automatic trash rakes provide continuous or scheduled cleaning, eliminating manual labor and downtime.

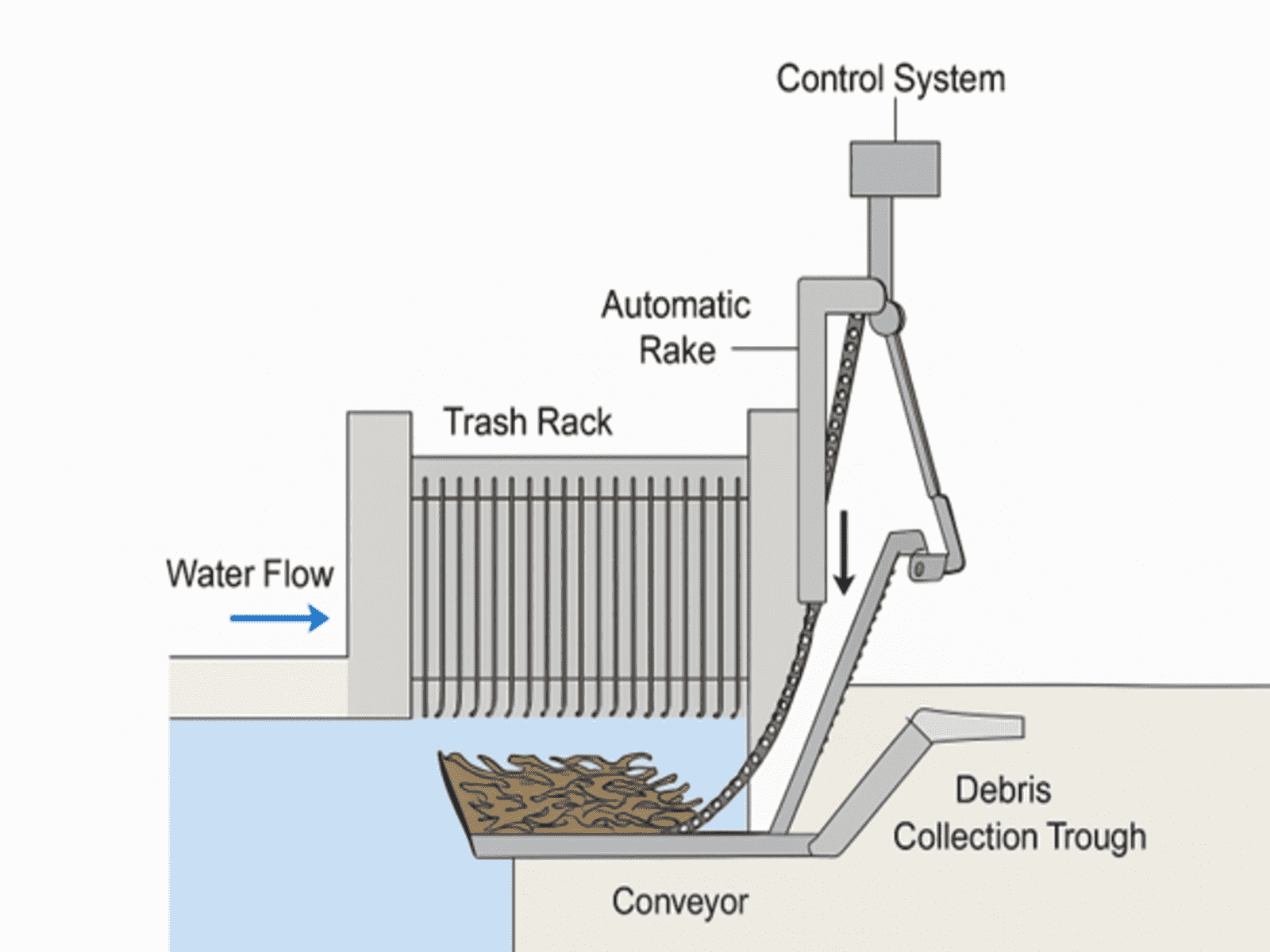

2. Working Principle

- The trash rack is installed at the intake.

- An automatic rake mechanism (mechanical or hydraulic) moves vertically along the rack.

- The rake teeth engage debris trapped on the rack.

- The debris is lifted upward, guided into a collection trough or conveyor system.

- From there, debris is disposed of downstream or taken to landfill/biomass use.

- The system can operate on:

- Scheduled cleaning cycles

- Differential head sensors (trigger when pressure difference indicates clogging)

3. Components

- Rake Arm / Grab → With teeth to engage debris.

- Lifting Mechanism → Winch, hydraulic cylinder, or chain-driven motor.

- Guide Rails → Ensure smooth rake movement along the trash rack.

- Control System → Automated via PLC/SCADA with remote operation.

- Debris Conveyor / Trough → For collection and removal.

- Differential Pressure Sensors → Detect clogging level on racks.

4. Significance in Hydropower

- Maintains Hydraulic Efficiency

- Prevents head loss at intake, keeping turbines at optimal performance.

- Protects Equipment

- Stops large debris from reaching traveling screens or turbines.

- Reduces erosion, cavitation, and turbine blade damage.

- Reduces Operational Cost

- Eliminates need for manual cleaning (dangerous & labor-intensive).

- Reduces plant downtime.

- Handles Extreme Conditions

- Efficient during flood season, ice buildup, or heavy debris inflows.

- Environmentally Friendly

- Collected debris can be reused (wood for biomass, organic matter for compost).

- Prevents downstream pollution.

- Safety & Automation

- Remote monitoring via IoT & AI:

- Sensors monitor debris load.

- AI optimizes cleaning intervals.

- Prevents unnecessary energy use.

- Remote monitoring via IoT & AI:

5. Types of Auto Trash Rakes

- Cable-Operated Rakes → A winch lifts debris with a grab.

- Hydraulic Arm Rakes → Hydraulic cylinders move rake teeth.

- Chain-Driven Continuous Rakes → Multiple rakes attached to chains, operating in cycles.

- Rotating Drum Screens with Rakes → Used in some modern plants with high debris loads.

6. Design Considerations

- Intake Size & Flow Rate → Determines rake size and power.

- Debris Load & Seasonal Variations → Floods, ice, vegetation cycles.

- Structural Strength → Rake must handle logs, stones, even ice blocks.

- Automation Level → Integration with SCADA for smart operations.

- Maintenance → Rake chain, teeth, and hydraulic systems must be inspected regularly.

✅ In summary:

The Auto Trash Rake is the first line of defense for hydropower plant intakes. It ensures uninterrupted flow, protects downstream equipment, reduces head loss, lowers maintenance costs, and increases plant reliability. Modern systems are integrated with IoT, SCADA, and AI for predictive operation and smart debris handling.