Water Screens Manufacturer in Hydroelectric Power Stations

Various screens used to filter water before entering turbines in hydroelectric power stations. Each type serves as a barrier at different stages of intake, protecting the plant from debris, silt, and biological matter.

🔹 Water Screens Manufacturer in Hydroelectric Power Stations

1. Coarse Screens (Trash Racks)

- Function: First line of defense at the reservoir or river intake.

- Construction: Heavy-duty steel bars with spacing typically 50–150 mm.

- Purpose: Stops large debris like logs, branches, plastics, ice blocks, and stones.

- Features:

- Simple, robust, fixed structure.

- Often cleaned using auto trash rakes.

- Must withstand high hydraulic pressure & impact loads.

2. Medium Screens (Bar Racks / Fine Trash Racks)

- Function: Provide intermediate filtration after trash racks.

- Construction: Steel or stainless-steel bars with 10–50 mm spacing.

- Purpose: Removes medium-sized debris, aquatic plants, and floating waste that pass coarse racks.

- Use: Often installed in front of traveling water screens for pre-screening.

3. Fine Screens (Traveling Water Screens)

- Function: Continuous removal of fine debris.

- Construction: Moving panels or mesh screens (openings 3–20 mm).

- Working: Panels rotate in a loop; debris is lifted and washed off by spray jets into a trough.

- Purpose: Filters small wood pieces, weeds, fish, plastics, algae mats.

- Features:

- Self-cleaning, automated.

- Protects turbines and cooling water systems.

- Can be designed with fish bypass systems for environmental compliance.

4. Drum Screens / Rotary Screens

- Function: Provide very fine screening at critical water intakes.

- Construction: Cylindrical drum with wire mesh or perforated panels (openings as fine as 2–5 mm).

- Purpose: Removes small debris, silt, algae, fish larvae.

- Features:

- Rotates slowly; water flows through drum surface.

- Debris removed by spray water jets or brushes.

- Commonly used in cooling water channels for hydro & thermal power plants.

5. Micro Screens / Wedge Wire Screens

- Function: Used where high water clarity is required.

- Construction: Stainless steel wedge wire mesh; openings down to 1–2 mm.

- Purpose: Filters fine sediments, suspended solids, plankton.

- Features:

- Low head loss due to wedge design.

- Sometimes used as secondary filtration for turbine cooling systems rather than main penstock.

6. Fish Protection Screens

- Function: Specialized screens to protect aquatic life.

- Types:

- Inclined Bar Screens → Fish slide along to bypass channel.

- Rotary Fish Screens → Drum or disc type, guiding fish safely back to river.

- Purpose: Ensure environmental compliance, prevent turbine fish kills.

- Mesh size: Typically 3–10 mm, depending on fish species.

7. Automatic Self-Cleaning Screens

- Function: Smart filtration systems for modern unmanned hydro stations.

- Working: Use backwash jets, suction nozzles, or brushes to clean mesh automatically.

- Purpose: Reduce manual maintenance, maintain consistent hydraulic performance.

- Features: Integrated with SCADA/IoT for remote monitoring of head loss and debris load.

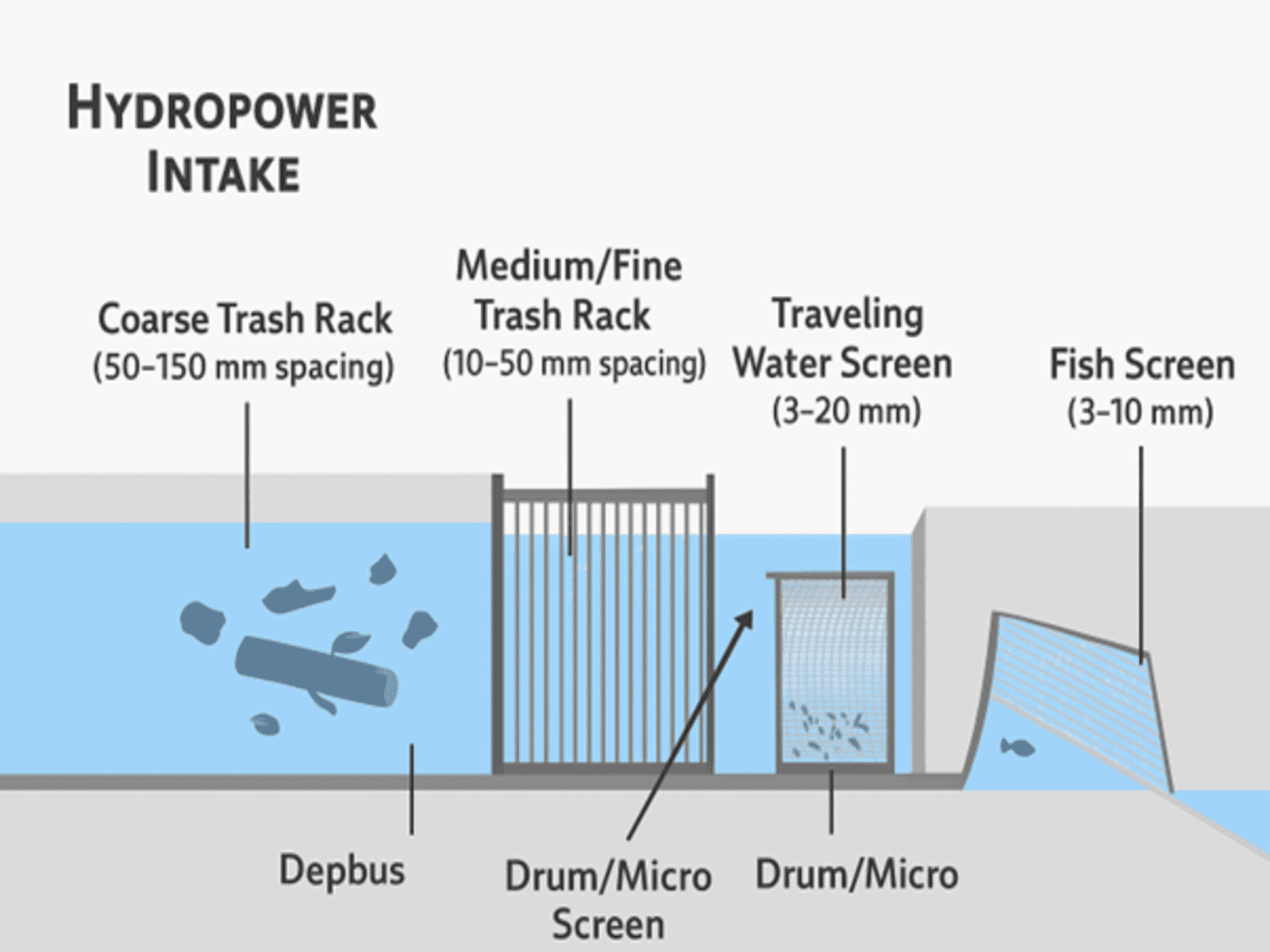

🔹 Typical Water Screening Arrangement at Hydropower Intake

- Coarse Trash Rack (50–150 mm spacing) → Blocks logs, stones, large debris.

- Medium/Fine Trash Rack (10–50 mm spacing) → Stops medium debris.

- Traveling Water Screen (3–20 mm) → Continuous cleaning, protects turbines & cooling.

- Drum / Micro Screens (0.1–5 mm) → Optional, for fine protection & cooling water systems.

- Fish Screens (3–10 mm) → Installed where biodiversity protection is mandatory.

✅ In summary:

Hydroelectric power stations use a multi-stage screening system — starting with coarse trash racks, moving through traveling fine screens, and optionally ending with drum/micro screens for cooling water — all working together to protect turbines, optimize efficiency, and safeguard the environment.