IoT and Artificial Intelligence applications in the mining industry,

Across key domains such as equipment monitoring, ore flow tracking, safety, fleet management, and more.

Mining industry use cases for IOT, Artificial Intelligence in, Equipment health monitoring, Ore flow monitoring & theft prevention, Worker Safety and Hazard Monitoring, Fleet Management & Optimization, Environment monitoring and compliance, Smart Energy Management, Smart energy management, Inventory and consumables Tracking, Remote operation & automation. Please elaborate more in details in regard to IOT and ARTIFICIAL INTELLIGENCE

📡 1. Equipment Health Monitoring

IoT Integration

- Edge devices and condition-monitoring sensors (vibration, acoustic emission, thermographic, oil particle counters, pressure transducers) are installed on key equipment such as haul trucks, draglines, crushers, SAG mills, and pumps.

- Data is transmitted using LoRaWAN, Zigbee, NB-IoT, or LTE/5G to a central data aggregation platform or SCADA system.

- Parameters monitored include bearing temperature, shaft alignment, lubrication oil quality, hydraulic pressure, and motor current.

AI Capabilities

- Machine Learning (ML) models (Random Forest, SVM, LSTM) perform predictive analytics to forecast component failures using historical and real-time sensor data.

- AI algorithms detect multi-dimensional anomalies and issue maintenance alerts.

- Integration with CMMS (Computerized Maintenance Management Systems) enables dynamic maintenance scheduling based on equipment condition rather than fixed intervals.

Technical Outcomes

- Reduction in Mean Time Between Failure (MTBF).

- Enhanced Overall Equipment Effectiveness (OEE).

- Minimized unplanned shutdowns and maintenance cost.

🧱 2. Ore Flow Monitoring & Theft Prevention

IoT Integration

- Load cells and belt scales integrated with conveyors and weighbridges to measure real-time mass flow rates.

- RFID/GPS tags on ore-carrying trucks enable geo-fencing and traceability.

- Optical sensors (IR or laser-based) detect belt misalignment or carryback that may indicate tampering.

AI Capabilities

- Computer vision models analyze video streams to detect irregular ore loading patterns.

- Data correlation between mine face output, truck dispatch, and mill feed is done using AI-based data reconciliation algorithms to detect ore pilferage or under-reporting.

- Graph analytics can reveal ore loss patterns or route diversion indicative of theft.

Technical Outcomes

- Real-time material accounting and inventory auditing.

- Improved ore reconciliation accuracy.

- Significant reduction in theft and ore leakage.

🦺 3. Worker Safety & Hazard Monitoring

IoT Integration

- Wearable sensors embedded in PPE (smart helmets, vests, boots) collect physiological data: heart rate, SpO₂, fatigue index, fall detection.

- Fixed gas sensors (NDIR, PID, electrochemical) detect hazardous gases: CH₄, CO, NOx, H₂S.

- Vibration and ground displacement sensors monitor seismic activity and structural instability in underground operations.

AI Capabilities

- Real-time decision systems powered by AI models classify risk levels and trigger automated alarms or evacuation protocols.

- AI-enabled facial recognition and pose estimation ensure worker compliance with PPE and proper behavior in confined or high-risk areas.

- Predictive AI models assess heat stress and fatigue risk based on historical exposure and real-time biometrics.

Technical Outcomes

- Reduced incidents of toxic exposure, fatigue-related accidents, and structural failures.

- Real-time proactive safety interventions.

- Improved compliance with MSHA/OSHA safety regulations.

🚛 4. Fleet Management & Optimization

IoT Integration

- Each mobile asset (truck, loader, excavator) is equipped with GNSS modules, CAN bus readers, and onboard telematics to capture fuel consumption, engine load, idling time, and travel route.

- Data transmission is done via satellite uplinks, mesh networks, or private LTE networks in remote mining areas.

AI Capabilities

- AI-based route optimization algorithms (like Dijkstra’s, A*) analyze haul road topology and live traffic to reduce fuel consumption and time.

- Reinforcement learning systems continuously optimize haul cycle time and truck-shovel matching.

- Predictive AI models forecast fleet maintenance events and fuel usage trends.

Technical Outcomes

- Reduction in fuel cost per ton moved.

- Higher fleet utilization efficiency.

- Decreased carbon emissions.

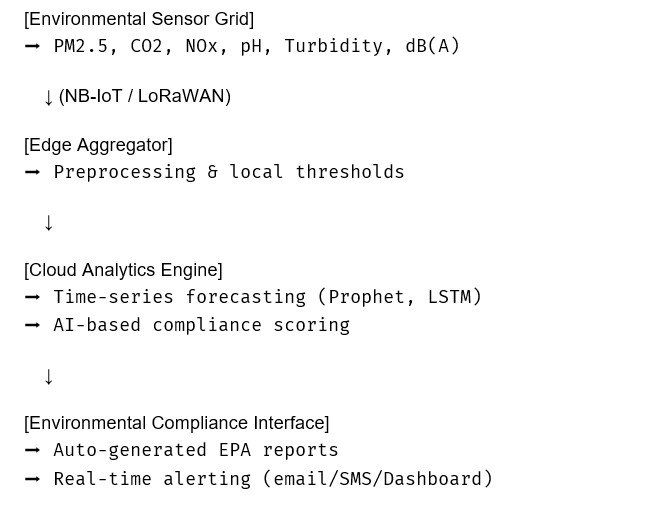

🌱 5. Environmental Monitoring & Compliance

IoT Integration

- Air quality monitoring stations use PM2.5, SO₂, NOx, and VOC sensors.

- Water quality monitoring includes pH, ORP, turbidity, TDS, and heavy metal detection using optical and electrochemical sensors.

- Noise and vibration sensors (MEMS accelerometers, geophones) are deployed at boundary zones and blast sites.

AI Capabilities

- Time-series forecasting models (ARIMA, Prophet) predict future pollutant levels.

- Multivariate regression and anomaly detection algorithms identify non-compliance triggers.

- AI automates ESG (Environmental, Social, Governance) reporting with dynamic dashboards and real-time alerts.

Technical Outcomes

- Enhanced ability to maintain continuous environmental compliance.

- Early warning of potential regulatory breaches.

- Better corporate sustainability reporting.

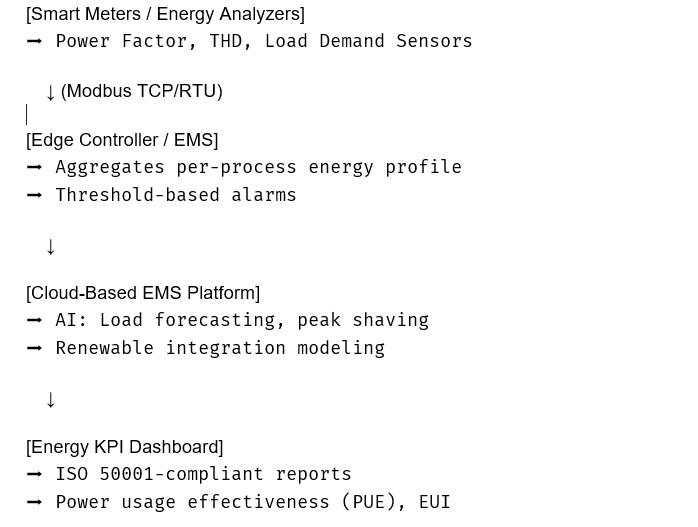

⚡ 6. Smart Energy Management

IoT Integration

- Smart energy meters and submeters monitor power consumption at feeders, MCC panels, dewatering systems, lighting, and HVAC.

- Real-time power quality analyzers capture harmonics, power factor, voltage sag/swell, and THD.

AI Capabilities

- Energy disaggregation algorithms isolate energy usage by asset or process.

- AI models detect inefficiencies in pump/motor operation or HVAC control.

- AI enables load forecasting, demand response, and battery storage optimization (if integrated with renewables).

Technical Outcomes

- Reduced energy intensity (kWh/ton).

- Decrease in peak demand charges.

- Compliance with ISO 50001 Energy Management System.

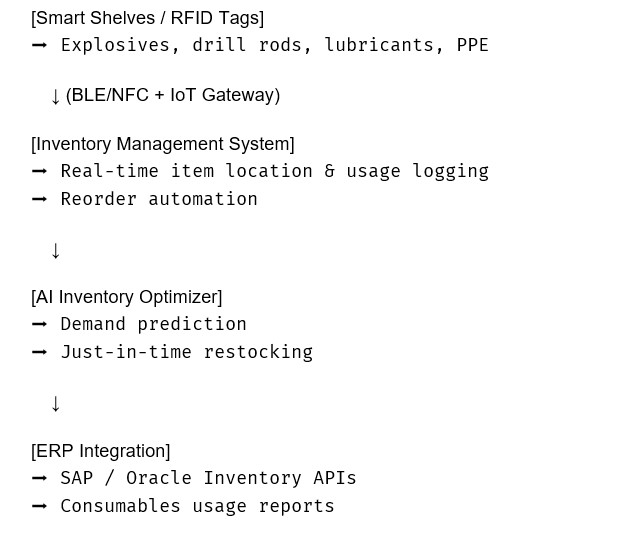

🧾 7. Inventory and Consumables Tracking

IoT Integration

- Use of RFID, NFC, and smart bin weight sensors for tracking fuel, drill bits, explosives, lubricants, PPE, and critical spares.

- Automated stock level detection and reorder alerts via IoT-connected shelves or bins.

AI Capabilities

- AI-based demand forecasting models optimize reorder points and safety stock levels.

- ML algorithms recommend supplier performance scoring, delivery scheduling, and budget control.

Technical Outcomes

- Just-in-time (JIT) inventory management.

- Reduced inventory carrying cost.

- Avoidance of stock-outs and production delays.

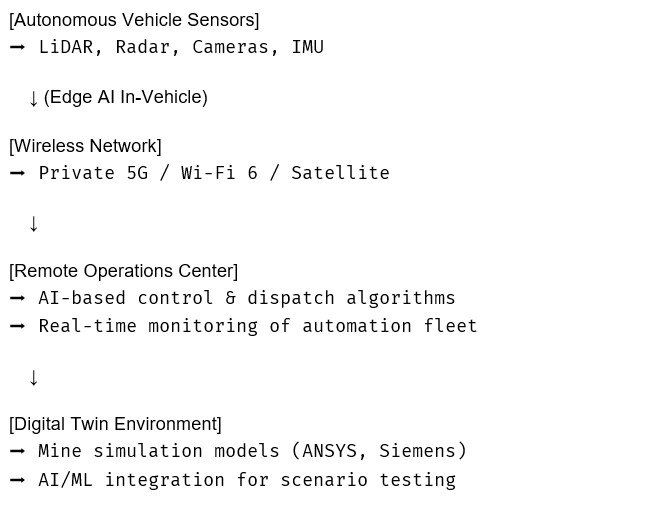

🖥️ 8. Remote Operation & Automation

IoT Integration

- Autonomous haul trucks, drills, and LHDs are equipped with LiDAR, radar, cameras, inertial navigation systems, and V2X communication modules.

- IoT-enabled remote operations centers control and monitor operations across geographically isolated mines.

AI Capabilities

- Autonomous decision-making algorithms allow equipment to navigate, avoid obstacles, and perform tasks with minimal human intervention.

- Digital Twin models simulate mine operations for planning and virtual commissioning.

Technical Outcomes

- Reduced manpower requirement in hazardous zones.

- Increased 24/7 operational capacity.

- Higher operational safety and efficiency.

✅ Conclusion

The integration of IoT infrastructure (sensors, connectivity, edge computing) with AI models (ML, CV, NLP, optimization) enables the digital transformation of the mining industry, offering:

- Data-driven decisions across the value chain

- Real-time visibility into operations

- Enhanced safety, productivity, and sustainability

- Full scalability for remote, autonomous mining operations

🔄 Summary Table

| Use Case | IoT Contribution | AI Contribution | Key Benefit |

| Equipment Health Monitoring | Sensors for vibration, temp | Predictive maintenance | Less downtime |

| Ore Flow Monitoring | Load sensors, tracking | Theft detection algorithms | Reduce loss |

| Worker Safety | Wearables, gas sensors | Behavioral AI | Save lives |

| Fleet Optimization | GPS, fuel sensors | Routing optimization | Save fuel & time |

| Environmental Monitoring | Air/water sensors | Compliance modeling | Avoid penalties |

| Energy Management | Smart meters | Forecasting & optimization | Lower costs |

| Inventory Tracking | RFID/barcodes | Demand prediction | Efficient stock control |

| Remote Operation | Connected machines | Autonomous systems | Boost productivity |

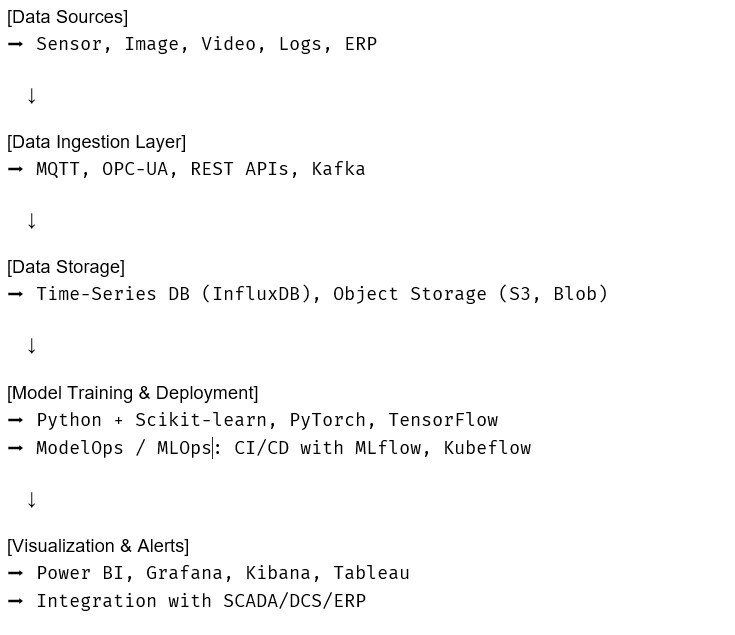

AI, ML ARCHITECTURE

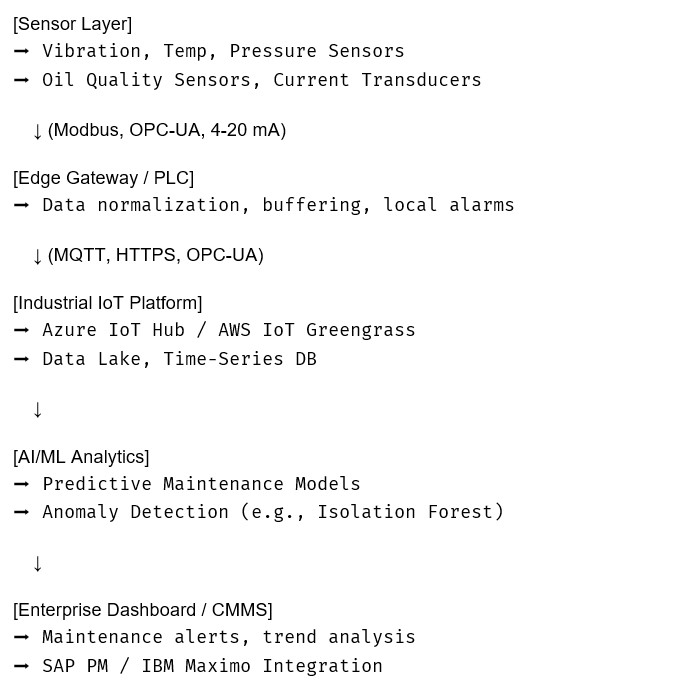

🛠️ 1. Equipment Health Monitoring

System Architecture

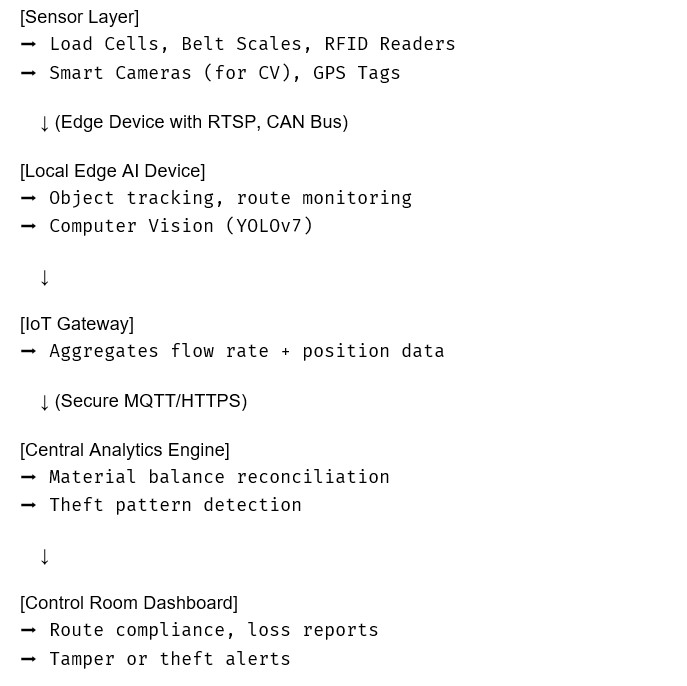

🪨 2. Ore Flow Monitoring & Theft Prevention

System Architecture

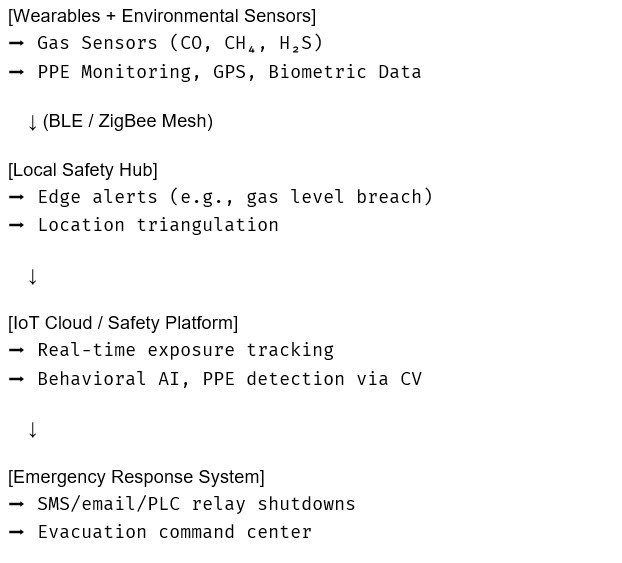

🧍♂️ 3. Worker Safety & Hazard Monitoring

System Architecture

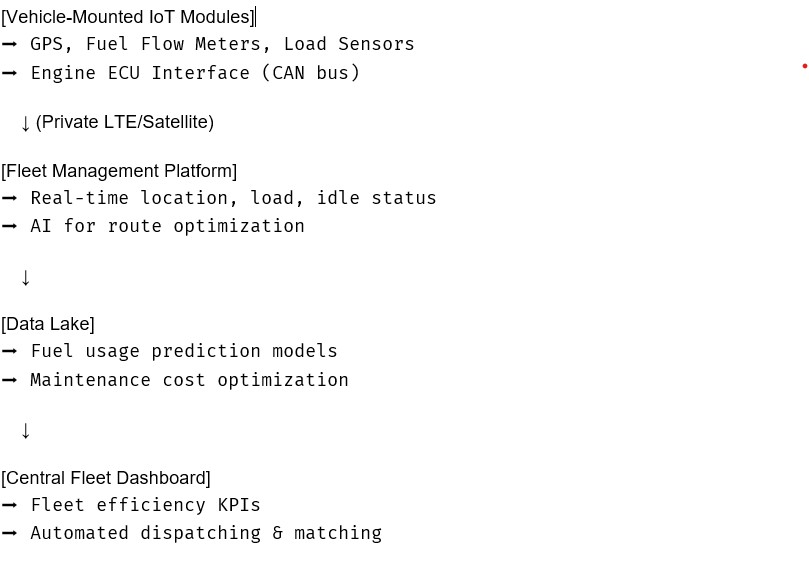

🚚 4. Fleet Management & Optimization

System Architecture

🌿 5. Environmental Monitoring & Compliance

System Architecture

⚡ 6. Smart Energy Management

System Architecture

📦 7. Inventory and Consumables Tracking

System Architecture