Use of IoT & AI in Mining Industry for Inventory & Consumables Tracking

How IoT (Internet of Things) and Artificial Intelligence (AI) are used in the mining industry for inventory and consumables tracking, including system architecture, components, and benefits:

🏗️ 1. Background and Importance

Mining operations rely on a wide range of consumables and spare parts, such as:

- Blasting materials (explosives, detonators)

- Drill bits, lubricants, and cutting fluids

- Wear parts for crushers, mills, conveyors

- Safety gear, PPE kits, filters

- Diesel, hydraulic oil, greases

- Conveyor belts, cables, and electrical spares

Poor inventory visibility leads to:

- Stockouts, causing unplanned downtime

- Overstocking, tying up capital

- Loss or theft, especially for high-value or hazardous materials

- Inefficient procurement and delays

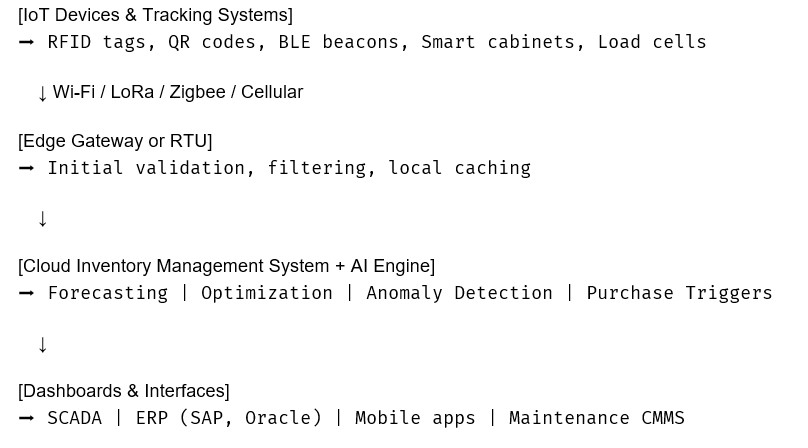

📶 2. IoT Use in Inventory & Consumables Tracking

A. RFID (Radio-Frequency Identification) Tags

- Passive RFID tags attached to consumables and spare parts

- Readers at entry/exit points (e.g., stores, workshops, tool cribs)

- Automates tracking of movement, usage, issuance, and returns

B. BLE (Bluetooth Low Energy) & LoRa Sensors

- For tracking high-value assets or tools in real-time over wide areas

- Used to monitor tool usage in workshops, mining sites

C. Weight Sensors & Load Cells

- Measure remaining quantity in:

- Diesel tanks

- Lubricant drums

- Chemical dosing tanks

- Explosives magazines

D. Barcode / QR Code Integration

- Smart handheld scanners used by warehouse staff for:

- Stock checks

- Issuance and returns

- Batch and expiry tracking

E. Smart Cabinets & Vending Machines

- Lockable units with IoT control

- Used for automatic dispensing of PPE, tools, or consumables

- Access logged via RFID badges or biometrics

🧠 3. Artificial Intelligence Applications

A. Demand Forecasting

- AI uses historical usage data, production schedules, and equipment health data to:

- Predict future consumption

- Plan reordering automatically

- Prevent emergency procurement

B. Inventory Optimization

- Machine learning models determine:

- Optimal reorder points (ROP)

- Economic order quantity (EOQ)

- Just-in-time (JIT) stocking strategies

C. Anomaly Detection

- AI flags:

- Unusual withdrawals (potential theft or hoarding)

- Sudden spikes in consumption (possible equipment issues)

- Expired stock being issued

D. Automated Procurement Triggers

- AI-powered systems generate purchase requests (PRs) when:

- Inventory falls below thresholds

- Predicted lead time and consumption risk stockout

E. Usage Pattern Recognition

- AI identifies:

- Which crews or shifts consume more

- Which tools or spares fail more frequently (linked to operator behavior)

🧩 4. System Architecture

🧾 5. Use Case Example: Lubricant Inventory Tracking

Problem:

Frequent stockouts of hydraulic oil disrupted underground mining equipment operations.

Solution:

- IoT load cells installed under lubricant tanks

- AI forecasted consumption patterns based on equipment hours and maintenance logs

- Automated PRs sent to procurement 5 days before depletion

- Alerts set for unauthorized withdrawals

Outcome:

- 25% reduction in unplanned downtime due to consumable shortage

- Optimized inventory levels with no overstocking

📊 6. Key KPIs Tracked

| KPI | Description |

| Inventory Turnover Ratio | How frequently stock is consumed and replaced |

| Stock-out Incidents | Number of times critical stock reaches zero |

| Inventory Accuracy % | Matches between system and actual quantity |

| Lead Time Compliance | Procurement lead time accuracy |

| Stock Holding Cost | Total cost of holding excess inventory |

🔐 7. Security and Safety Integration

- Explosives and chemical tracking via RFID to meet DGMS and safety regulations

- Tamper alerts for unauthorized access to controlled items

- AI compliance dashboards for audit trails and safety reporting

✅ 8. Benefits of IoT & AI in Inventory Management

| Benefit | Description |

| 📉 Reduced Downtime | Spares and consumables always available when needed |

| 🔄 Just-in-Time Inventory | Minimized holding cost and space |

| 🔐 Improved Security | Theft and misuse detection |

| ⚙️ Operational Efficiency | Streamlined issuance, returns, and usage logging |

| 📈 Data-Driven Procurement | Smart reordering and budget planning |

| 📋 Regulatory Compliance | Track hazardous material flow and audit readiness |