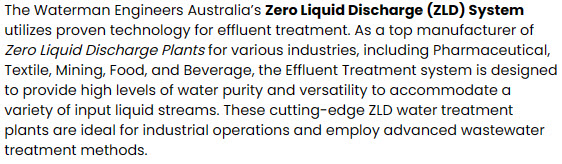

Zero Liquid Discharge System

Waterman Engineers Australia is one of the leading manufacturers of Zero Liquid Discharge system. A ZLD system is a treatment process which is used to remove all the liquid waste from a system. The goal of ZLD water treatment is to reduce wastewater economically and produce potable water that is fit for normal use. Zero discharge system is an advanced treatment method that comprises ultrafiltration, reverse osmosis, evaporation and fractional electro deionization. And we are a well-known supplier of ZLD systems.

Why is there a need for Zero Liquid Discharge System?

In many Industries, such as power, oil & gas, chemicals, mining and others, a large amount of wastewater is generated that has to be managed. Conventionally, this discharge of wastewater is done via a plant outfall to a surface water body like an evaporation pond, or in some cases deep well injected. These practices lead to many environmental concerns by the public in many regions of the world, as water is a scarce source and its management should be monitored. These concerns have resulted in the establishment of ZLD processes by many industries to lessen their environmental footprint and enhance sustainability. And, Waterman Engineers Australia are best ZLD suppliers you can find for this system.

If we talk about the world, ZLD has become necessary in India during the last decade due to heavy contamination of local waters by industrial wastewater in order to ensure the future of their rivers and lakes. In Europe and North America, the urge towards ZLD has been raised due to the high costs of wastewater disposal at inland facilities. So, as an exporter of Zero Liquid Discharge system, we keep the requirements of different regions in mind, and provide these systems accordingly.

Properties of Zero Liquid Discharge System

The properties of a Zero Liquid Discharge system can vary depending on the specific design and technology used. However, some common properties of ZLD systems include:

Water Conservation: One of the primary objectives of ZLD systems is to conserve water by minimizing the discharge of liquid waste into the environment.

High Water Purity: ZLD systems are designed to produce high-quality water that is free from impurities and contaminants, which makes them suitable for use in many industrial processes.

Versatility: ZLD systems are often designed to accommodate a broad range of input liquid streams, which makes them versatile and suitable for use in different industries.

Advanced Wastewater Treatment: Zero liquid discharge systems use advanced wastewater treatment methods to remove impurities and contaminants from the effluent, producing high-quality water.

Waste Reduction: ZLD systems help reduce waste by reducing the volume of liquid waste that needs to be disposed of and by producing a concentrated, solid waste material that can be safely disposed of.

Energy Efficiency: ZLD systems can be energy-intensive due to the high energy requirements of evaporation and other wastewater treatment processes. However, advances in technology are making Zero liquid discharge systems more energy-efficient and cost-effective.

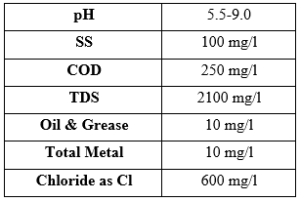

Zero Liquid Discharge System Technical Specification to Focus

Technical specifications for a Zero Liquid Discharge system can vary depending on the specific system and manufacturer, but here are some common specifications that are important:

1. Water source: The Zero Liquid Discharge System should be able to treat water from a specific source, such as industrial effluent or brackish water.

2. Flow rate: The flow rate of the Zero Liquid Discharge System is the amount of water that can be treated per hour or day.

3. Feed water quality: The quality of the water that is fed into the system should meet certain specifications, including parameters such as pH, TDS, and other contaminants.

4. Treatment stages: The Zero Liquid Discharge System typically includes multiple stages of treatment, which may include processes such as pre-treatment, ultrafiltration, reverse osmosis, evaporation, crystallization, and fractional electro deionization.

5. Recovery rate: The recovery rate is the percentage of water that is recovered for reuse after treatment.

6. Concentrate disposal: The concentrate is the waste stream generated from the Zero Liquid Discharge System, and the disposal method should be specified in the technical specifications.

7. Materials of construction: The Zero Liquid Discharge System should be constructed using materials that are compatible with the feed water and treatment process, and that are corrosion-resistant and durable.

8. Operating conditions: The ZLD system should be able to operate within a specified range of temperature, pressure, and other conditions.

9. System automation: The Zero Liquid Discharge System may be equipped with automation and control systems to monitor and control the treatment process.

These are some important technical parameters to check for Zero Liquid Discharge System. For custom technical specifications, pls. contact us.

ZLD SYSTEM TECHNOLOGIES by Manufacturers:

- Falling Film Brine Concentrators

- Forced Circulation Crystallizer

- Horizontal Spray Film Evaporator

- Hybrid Systems with Membrane Pre-Concentrators

- Biological Treatment

- Solids Waste Handling

Zero Liquid Discharge Plant Benefits & Applications:

As Waste water recycling plant manufacturer, recover valuable resources from the wastewater which can either be sold or reused during industrial processes. Here are some examples:

- Production of valuable potassium sulphate (K2SO4), fertiliser from a salt mine

- Concentration of caustic soda, sodium hydroxide (NaOH) to 50 and 99% purity

- Minimise coal mine wastewater treatment costs by recovering pure sodium chloride which can be sold as a road salt.

- Decrease the volume of wastewater and lowers the costs of waste management.

- On site recycling of water, thus decreasing the need for water intake and meeting treatment requirements.

- Minimise the truck transportation costs for off-site disposal and the related environmental hazards

ZLD Plant Designs Factors:

What are the factors necessary to be considered while designing? Here they are:

- The respective contaminants in the discharge stream

- The volume of the dissolved material

- The required design flow rate

Concerned Chemicals For Zero Liquid Discharge Equipment:

As Zero liquid discharge plant manufacturer, Careful consideration of water chemistry is needed to design the zero liquid discharge system. The concerned chemical constituents for a zero liquid discharge system are as followed:

- Sodium

- Potassium

- Calcium

- Magnesium

- Barium

- Strontium

- Silica

- TDS/TSS

- COD/TOC/BOD

- pH

- Chloride

- Fluoride

- Sulfate

- Nitrate

- Phosphate

- Ammonia

- Boron

- Alkalinity

- Oil & Grease

Table 1: Chemical constituents of concerned while designing a zero liquid discharge system

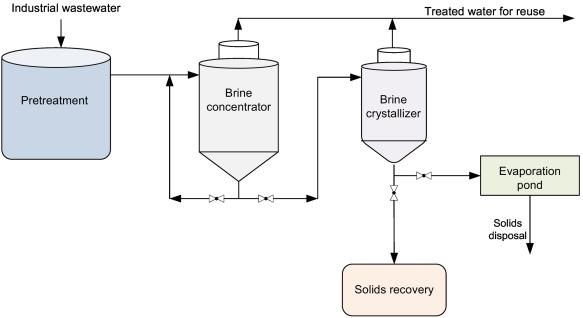

ZLD System Design:

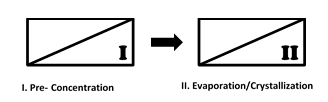

Regardless of many sources of wastewater stream, a ZLD system usually consisted of two steps as shown in figure

Pre-Concentration: Pre-concentration of brine generally obtained with membrane brine concentrators. These technologies are able to recover 60-80% of the water as per following processes shown in figure 3.

Evaporation/ Crystallisation: The next step, evaporation evaporates all the leftover water, collect it and direct it for reuse. The remaining waste then moves towards a crystallizer which boils all the water until all the impurities crystallise and filtered out as a solid as shown in the figure 4.

Effluent Treatment Plant:

The purpose of an effluent treatment plant, also known as an ETP, is to remove harmful contaminants from industrial wastewater so that it can be reused while also releasing clean water into the environment.

Depending on the industry like Pharmaceutical, Mining, Textile, industrial effluents comprise a range of different substances. Some effluents contain hazardous substances while others contain oils and grease (e.g., cyanide). Degradable organic contaminants are present in factory effluents from the food and beverage industry. Industrial wastewater comprises a variety of pollutants, necessitating the use of a specific treatment method termed ETP. Various types of Effluent Treatment Plants for different industries are available and known as Pharmaceutical Effluent Treatment Plant, Mining Effluent Treatment Plant, Textile Effluent Treatment Plant etc.

Parameters and ETP Standards:

Industry waste must adhere to the government's national standards for wastewater.

To ensure that the wastewater is treated to these requirements, the effluent treatment plant (ETP) or sewage treatment plant (STP) should be designed and operated in this manner.

How Does Effluent Treatment Plant Work?

The disposal of sewage and contaminated water is mostly dependent on effluent treatment plants. An ETP plant treats impurities such as colloidal matter, mineral particles, toxic substances, organic compounds, and other pollutants.

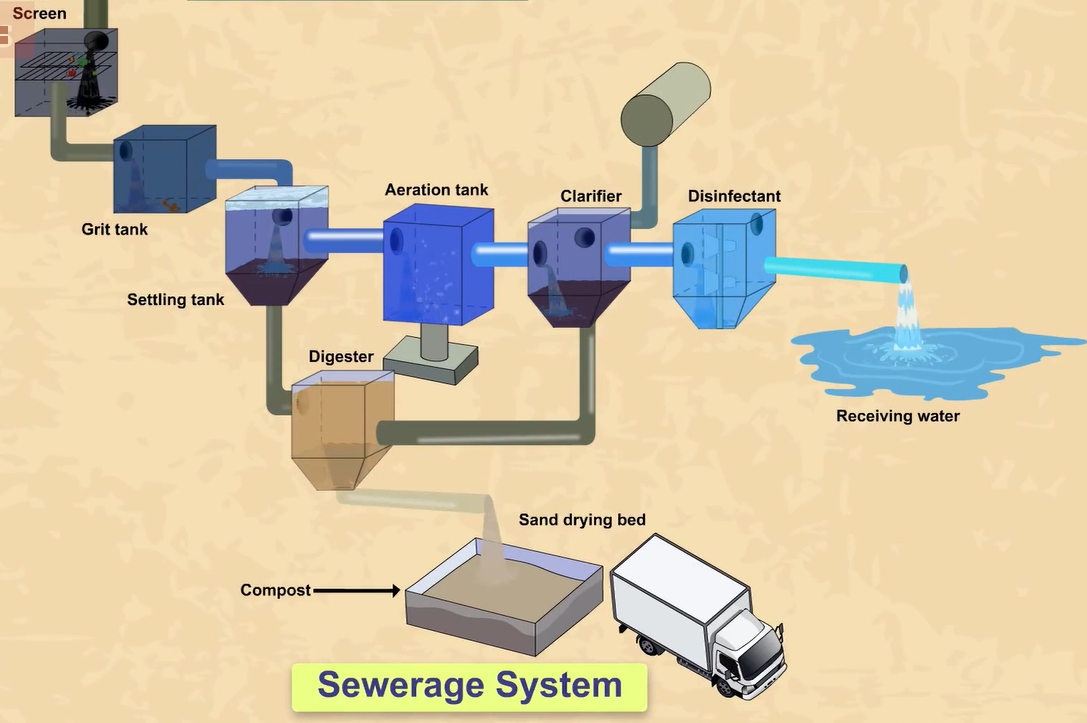

Sewage from our houses, hotels, industries, and other facilities is transported via sewerage systems in cities and towns to sewage treatment plants, where it is cleaned up and then certified safe to release into other water sources.

Wastewater is treated through several stages and procedures to remove contaminants.

- Physical contaminants

- Chemical contaminants

- Biological contaminants

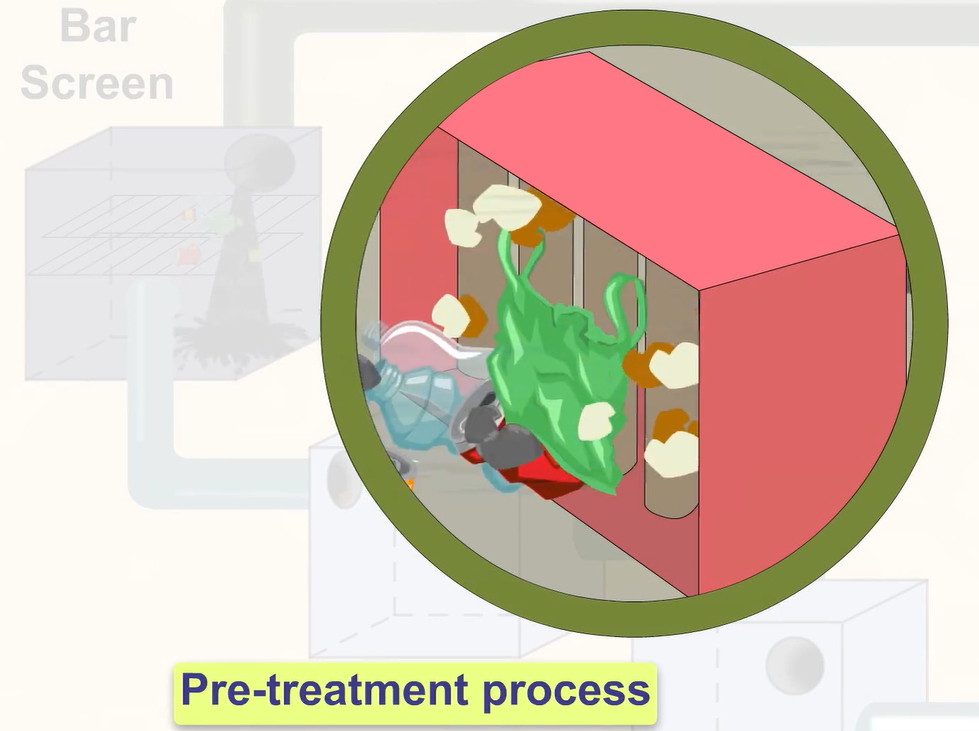

Effluent Pre-treatment Process:

In the pre-treatment stage, the sewage is passed through grids or vertical bars that can filter out big solids like paper, plastic, and metal cans.

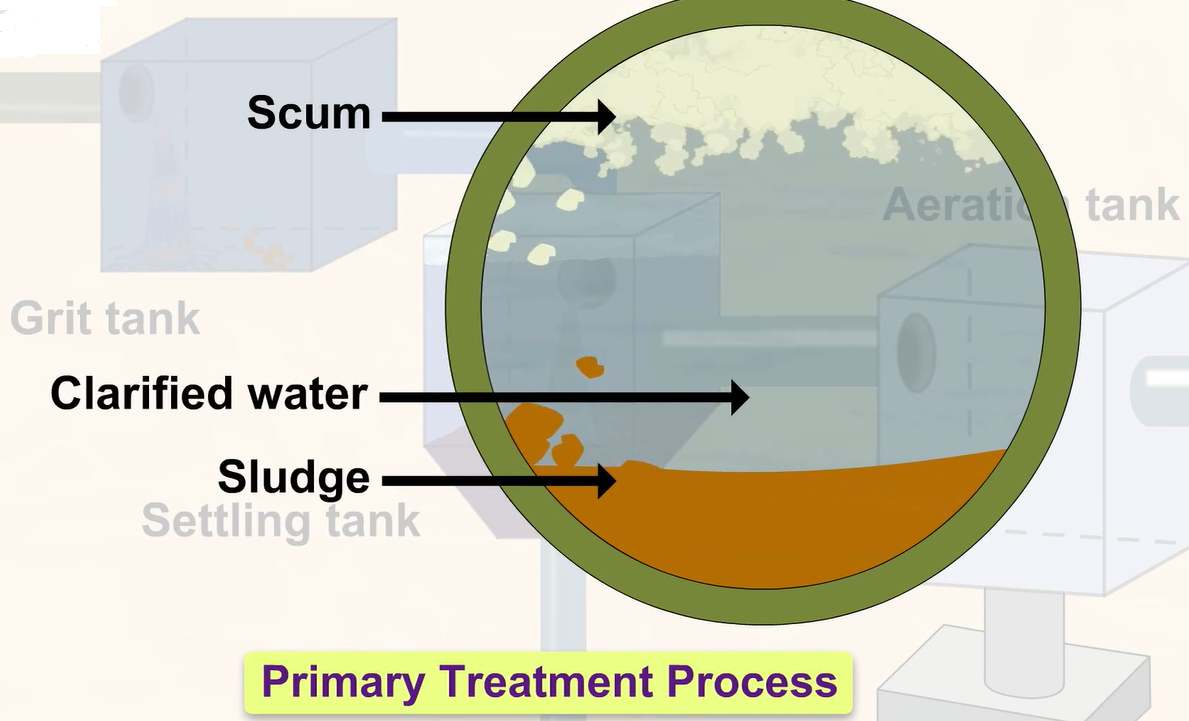

Primary Effluent Treatment Process :

Sand, pebbles, and soil sink to the bottom of the grid chamber because of the slow flow of sewage during the first treatment process.Wastes such as soap, oils, and grease rise to the surface when wastewater enters the settling tank, where solid wastes such as faeces are allowed to settle. Sludge and scum are the names for the waste material that sinks to the bottom and floats to the surface. After that, scum and sludge are removed every several days using the scraper and skimmer, respectively. Clarified water is the term for the water that is not used.

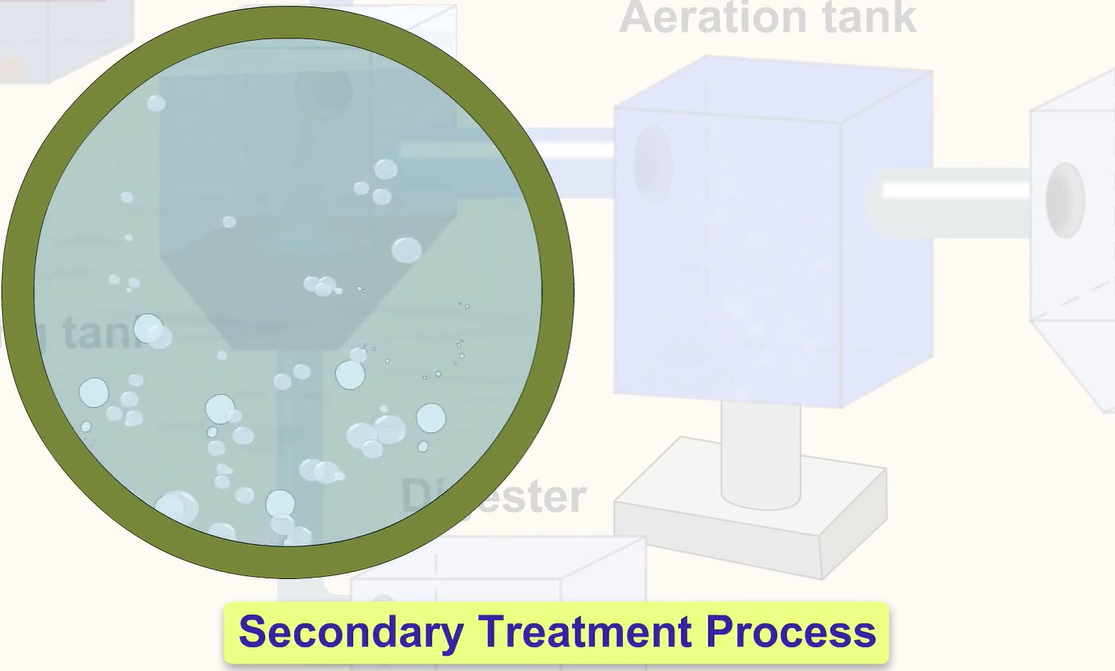

Secondary Effluent Treatment Process:

Organic or biological wastes are eliminated during the secondary treatment procedure. The process is biological. This is performed by transferring the purified water to an aeration tank equipped with air blowers that create bubbles of air to encourage the growth of aerobic bacteria that consume organic pollutants including food waste, faeces, and other creatures. Activated sludge then gravitationally separates out of the mixture as it moves from the aeration tank into the clarifier.

The digester is where anaerobic bacteria break down the activated sludge that has been created together with the sludge from the primary phase. The remaining water in the activated sludge drains through the sandpits after some of it evaporates from the mixture. The remaining dried sludge is then left behind and can be used to create compost or fertilisers.

ZLD stands for Zero Liquid Discharge, a system that is used to treat and reuse wastewater in a closed-loop system. The following are some common features of ZLD systems:- Pre-treatment: The first step in a ZLD system is pre-treatment, which involves removing solids and other contaminants from the wastewater. This is typically done using a sedimentation tank, a filter, or a clarifier.

- Evaporation: After pre-treatment, the wastewater is subjected to evaporation, which removes water from the waste stream and concentrates the remaining contaminants. This is typically done using multi-effect evaporators or thermal evaporators.

- Crystallization: In some ZLD systems, the concentrated waste stream is subjected to crystallization, which further removes water and results in a solid waste product that can be disposed of or processed further.

- Recycling: The purified water from ZLD systems can be recycled back into the industrial process, reducing the need for fresh water and helping to conserve water resources.

- Energy recovery: ZLD systems often use energy-intensive processes, such as evaporation and crystallization. However, these processes can also generate heat and other forms of energy that can be recovered and reused, reducing the overall energy consumption of the system.

- Monitoring and control: ZLD systems are typically equipped with monitoring and control systems that help to optimize the performance of the system and ensure that it is operating within design parameters.

Tertiary Effluent Treatment Process :

In the final stage of treatment, chlorine is used to eliminate, phosphorous, microorganisms and nitrogen compounds, including chemicals. To eliminate the microorganisms, chlorine pills are administered. Chlorination is the name of this procedure. The water is then directed into the bodies of water. So, if you are looking for Pharmaceutical ETP, Mining ETP or Textile ETP, you are at right place, Email your requirements to water@watermanaustralia.com

Zero Liquid Discharge System Frequently Asked Questions :

1. What does Zero Liquid Discharge entail?

In ZLD treatment, all sewage and effluents will either be treated through effluent treatment plants, reverse osmosis UF MF membranes and/or evaporated, allowing no effluents to be released. A Zero Liquid Discharge System's goals are to provide cleaner, reused water and discard of wastes properly, cutting disposal expenses and lowering your climate impact.

2. What influences the ZLD treatment system's components?

The precise features of a ZLD treatment unit will be determined by the amount of particulate material contained in the effluent, dissolved solids, dissolved and undissolved metal contents, colour and the concentration of particulate pollutants.

3. How does effluent treatment plant aid in the elimination of textile effluents?

Waterman Engineers Australia ZLD system assists in the disposal of waste from heavily polluting businesses, such the textile industry, in order to reduce contamination of groundwater and water sources.

4. What are the advantages of aiming for zero liquid discharge in a process industry?

Zero liquid discharge reduces pollution volumes and waste disposal costs; it reuses water on-site, cutting liquid acquiring risk and expenses. It also enhances sustainable development and the regulatory risk profile for future permitting, and certain processes potentially reclaim important materials, such as ammonium sulphate fertiliser or sodium chloride salt.

5. What is the goal of employing a zero liquid discharge system?

The overall targets for a zero liquid discharge technology are to remove sludge water discharge, create sediments for landfilling or reprocess, and recycle high-quality water that may be advantageously utilized. The design goals are to reduce the initial expenditure and system running costs. Furthermore, the infrastructure must be constructed with flexibility to accommodate the plant's demands while being safe and dependable.

6. What is effluent treatment plant?

An Effluent Treatment Plant (ETP) is a type of wastewater treatment plant where various physical, biological and chemical processes are employed to rectify the properties of the wastewater by removing harmful substances from it, in order to safely discharge it into the environment.

7. What is primary effluent treatment plant?

Primary effluent treatment unit is a subdivision of an ETP, it involves the sedimentation of solid waste within the water by means of gravity, removing floatable objects, and reducing the pollution to ease the subsequent treatment process. Primary Treatment aims to reduce the Biochemical Oxygen Demand (BOD) and Total Suspended Solids (TSS) in the wastewater.

8. What is secondary effluent treatment plant?

Secondary effluent treatment is the second stage in ETP which deals with the removal of biodegradable organic matter from the wastewater. This is accomplished by employing various microorganisms to biologically degrade contaminants. These biological processes can either be aerobic or anaerobic, each process utilizing a different type of bacterial community.

9. What is tertiary effluent treatment plant?

Tertiary water treatment is the final and third stage of an ETP, this involves a series of additional steps such as filtration, ion-exchange, activated carbon adsorption, electro dialysis, nitrification/de-nitrification to further reduce metals, nitrogen, organics, pathogens, phosphorus, and turbidity. This makes the treated water safe for recycle, reuse, or release into the environment.

10. What unit operations are part of effluent treatment plant?

Unit operations in effluent treatment plant include sedimentation, filtration, coagulation, flocculation, chlorination, ozonation, reverse osmosis, UV irradiation, and degasification.

11. What are limiting parameters of treated effluents?

Following are the limiting parameters of treated effluents:

1. Irrigation restrictions: The disposal of treated effluent for the purpose of irrigation needs to be handled carefully, it is advised that only grass, bushes, or trees with shallow root systems be used instead of edible plants.

2. Sludge Production: The by-product of the wastewater treatment operations is called sludge. A significant environmental challenge is presented by the excessive disposal of sludge into the landfills. The harmful contaminants in the sludge may seep out and might leak into the nearby water bodies/streams.

3. Environmental Footprint: The Wastewater treatment plants are the source of greenhouse gas emission from the system of wastewater collection, transport and treatment, i.e.: carbon dioxide (CO2), nitrous oxide (N2O) and methane (CH4) which result from biological processes occurring in wastewater.

12. What are parameters to be considered to design effluent treatment plants?

Following are the aspects to be considered before designing a wastewater treatment plant:

- Effluent Concentrations

- Area Selection/Footprint

- Chemical Ultra and Biological Scrubbers

- Characteristics of wastewater

- Requirement of treatment stages

- Neutralization

13. What equipment are part of effluent treatment plants?

An ETP employs various equipment for carrying out the required physical and chemical processes, the list of equipment in no order is as follows:

- Collection Tank

- Equalization tank

- Oxidization tank

- Neutralization tank

- Digital TDS meter

- Fluidized Bed Bioreactor

- Sludge Thickener Tank

- Clarifier Tank

- Coagulation Tank

- Sludge Filter Press

- Activated Sludge Tank

- Sand Filter

- Flash mixer

- Filtration

- Ultrafiltration and Water makeup

- Pumps/Blowers

- pH/Temperature Indicators and Controllers

- Level controllers

- TDS/DO meters

- Pipelines, valves, and accessories

14. Main criteria to be considered to treat mining effluent treatment plant?

The selection criteria are devised on four aspects, viz. environment, economic, social, and technical dimensions. Specific selection criteria are included for the themes:

- Environmental Dimension:

Following aspects have been opted for this theme:

- Mass inputs and energy consumption

- Impacts of the system (ecological integrity)

- Solid outputs of the system

- Gaseous outputs from the system

- Liquid outputs from the system

- Economic Dimension

- New project value

- Project performance

- Social Dimension

- Health and safety

- Quality of life

- Local and economic benefits

- Corporate citizenship

- Technical Dimension

- Adaptability

- Complexity

- Uncertainty

15. Main criteria to be considered to treat textile effluent treatment plants

The selection criteria are devised on four aspects, viz. environment, economic, social, and technical dimensions. Specific selection criteria are included for the themes:

- Environmental Dimension:

Following aspects have been opted for this theme:

- Mass inputs and energy consumption

- Impacts of the system (ecological integrity)

- Solid outputs of the system

- Gaseous outputs from the system

- Liquid outputs from the system

- Economic Dimension

- New project value

- Project performance

- Social Dimension

- Health and safety

- Quality of life

- Local and economic benefits

- Corporate citizenship

- Technical Dimension

- Adaptability

- Complexity

- Uncertainty

16. What is effluent recycling / wastewater recycling?

Water recycling, also known as water reclamation, is the process of treating and re-purifying industrial effluent before returning it to the same process, creating a closed loop.

17. What is role of multi effect evaporator in zero liquid discharge system?

The Multiple Effect Evaporator (MEE) in ZLD system is a device for effectively evaporating water by using the heat from steam, where all water is recovered, and contaminants are reduced to solid waste. Water is boiled in a series of vessels in a MEE, each held at a lower pressure than the one before it. MEE enables efficient recovery and reuse of high volumes of water, as well as the recycling of raw materials present in the effluent stream, consequently reducing the costs associated with the transport and management of waste.

18. What is role of agitated thin film dryer / agitated thin film evaporator in zld system?

Agitated Thin Film Dryer (ATFD) is an apparatus employed for continuous processing of concentrated material into dry solids. The ATFD is the perfect remedy for thermal treatment and heat-sensitive items when low operating temperatures and vacuum working pressures are necessary. It is the final stage of Zero Liquid Discharge plant.

19. How crystalliser plays role in zero liquid discharge system?

A crystallizer converts wastewater into two streams, one containing solid waste with useful resources and the other as recyclable water. The function of the vacuum crystallizer is being designed to evaporate all solvents and leave a highly concentrated, pasty, gelatinous, or shiny product.

20. How reverse osmosis system helpful in ZLD systems?

RO Plant aids in reclaiming/recovering the water content of the waste stream (permeate). First, semi-permeable membranes are used to reduce the water content of the filtered wastewater by 40 to 50 percent. The second stage of the process involves pumping the liquid through membranes at extremely high pressures (up to 120 bar), which further reduces the water content by 30 to 40%.

This indicates that the concentrate's water content has been decreased by up to 60–70% by the time it enters the brine concentrator following the two-stage reverse osmosis procedure.

21. Main pre-treatment before reverse osmosis systems in zero liquid discharge systems

Following pre-treatment is required for RO process in ZLD system:

- Filtration

- Scale Inhabitation

- Ion Exchange

- Organics Removal by Activated Carbon

21. How important effluent recycling / zero liquid discharge system to save water resources?

ZLD application is expanding internationally as a crucial wastewater management technology to lower water pollution and increase water availability. Recycling prevents the release of wastewater into the environment. Further, the recovery of salt and water lowers the operational expenses. Environmental and industrial sustainability is also strengthened. Thus, ZLD system aids environmental restoration and promotes circular economy.