The water supply contains several chemical and biological contaminants. As a result, raw water cannot be utilised for drinking or other reasons, necessitating the installation of water filtration systems. This problem can be solved by installing a water filtering system.

This facility is required in the business and corporate sectors as well as other industries that require filtered water since it is frequently utilised to purify water. Ultrafiltration is regarded to be more effective than traditional filtration methods since it can filter out dangerous material, biological and chemical components, and several other contaminants. Although other forms of water can also be cleaned inside of a water filtration plant, most of these plants filter drinking water fit for human utilization.

In order to meet the demands of customers, we at Waterman Engineers Australia provide complete projects for the water filtration plants that are created under close monitoring and using cutting-edge machinery and technology.

Water Filtration Plant Working:

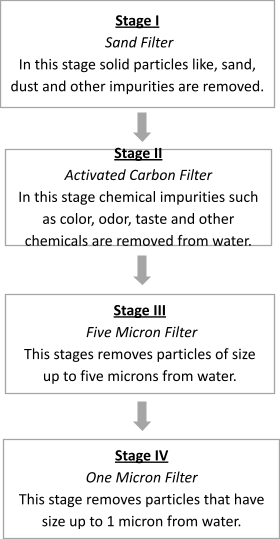

The filtration plant cleans and purifies water in four stages.

Water Filtration Stages:

Stage I

Sand Filter In this stage solid particles like, sand, dust and other impurities are removed.

Stage II

Activated Carbon Filter In this stage chemical impurities such as color, odor, taste and other chemicals are removed from water

Stage III

Five Micron Filter This stages removes particles of size up to five microns from water.

Stage IV

One Micron Filter This stage removes particles that have size up to 1 micron from water.

Key Features of Water Filtration Plant:

- High-Quality effluent with turbidity output water: ≤ 0.2NTU

- Suspended particulate matters >2um

- Lower carbon footprint

- Low energy cost and easy operation

- No chemical and pollutant

Commercial Water Treatment Plant:

The water treatment plants are for commercial buildings like resorts, restaurants, hotels, public places, etc. the filtration plant removes, dust, rust, fungus, and other physical and chemicals impurities from water so that it is fit for consumption. Depending upon the need of the customer Waterman Engineers Australia as an exporter offer a wider range of water filtration plants.

Ultrafiltration Plants Working:

The water filtration technology in ultrafiltration plant design uses a semi-permeable membrane to remove impurities from water. Reverse Osmosis system is applied in these filtration plants to clean and purify water. The benefit of using this technology is that it can remove several molecules and ions, particles, as well as bacteria from water. The impurities are retained on the pressurized side of the membrane whereas the water passes through the membrane to the other side. Moreover, as suppliers of water filtration plants, the ultrafiltration plant price depends on the client’s requirements.

Key Features of Commercial Water Filtration Plant:

- Low cost and easy operation.

- In-place system, cleaning is optional when necessary.

- High concentrate recycling with a good rejection rate.

- >Large capacity and suitable for industries as well.

Commercial Water Purification Plant Design Basis:

The raw water is (TDS: ≤2000ppm)

- Permeate output is optional according to the requirement (25℃)

- Seawater input temperature:4℃~45℃

Permeate output quality: TDS≤60-100 ppm, WHO direct drinking standard

Although the primary goal of water filtration system is to make drinking water safe, it's equally crucial to filter water for other uses. Regardless of how safe the water is, no one likes to drink stale water.

The availability and quality of the water source, sustainability evaluations of treatment, financial, social, and environmental factors, statutory requirements, and technology are some of the factors that influence the design and planning process for water filtration plant Every time we take on a project for a commercial water filtration plant, we work extremely hard to exceed every client's expectation.

Industrial Filtration Plant:

The filtration of water is a vital and critical part of the industry. Industries heavily rely on water and for them to work smoothly and efficiently, water purification is important. Water is used in various steps of the industrial process and water filtration is required in almost all the steps. To remove impurities, water has to go through sand filters, carbon filters, water softeners, and screen filters.

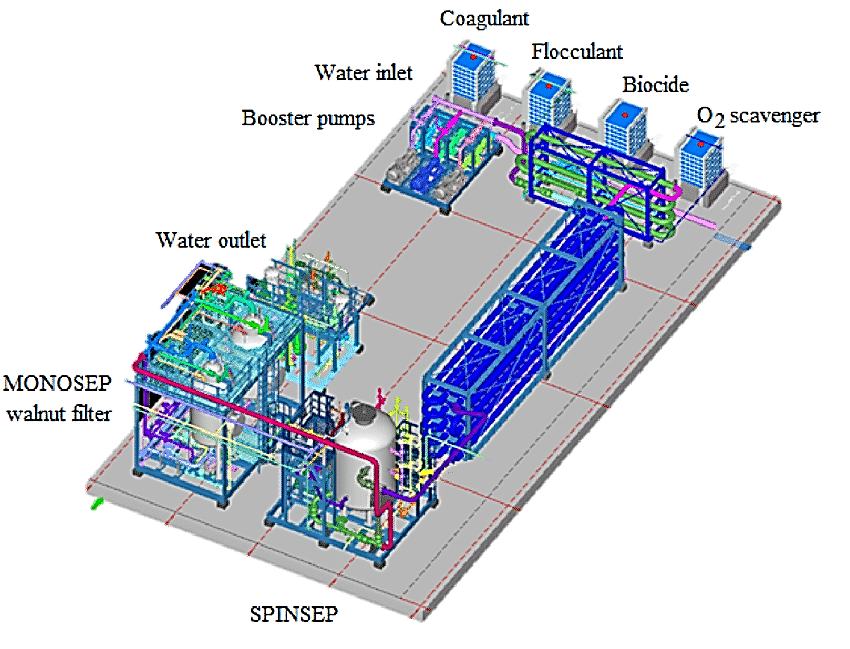

Industrial Filtration Plants Working:

Intake: water is drawn through gravity or pimps into the filtration plant. It passes through a metal grate or mesh screen that prevents large particles from entering the system.

Clarification: in this multistep process suspended particles are removed. It starts with coagulation in much the particles form clumps due to chemicals and pH adjusters. After this flocculation takes place that involves physical agitation and causes the formation of large particles. Then comes sedimentation in which the stream flows to a gravity settler and the particles settle down t the bottom known and sludge blanket. Then any remaining particles are removed by passing the stream through a sand filter.

Disinfection: if water is biologically contaminated, the pathogens can be removed by the application of chemical disinfectants, physical disinfectants, and membrane filtration.

Lime softening: This step removes the hardness of water by using lime pr lime soda which raises the pH of the water and causes mineral constituents to precipitate out of water.

Ion exchange: Hardness can also be removed in an XI unit. Water is passed through an acid cation resin charged with sodium. the resin captures calcium or magnesium ions and releases sodium on in the water.

Distribution: After filtration water is pumped or routed for use.

Industrial Water Purification System Design:

Advantages of Water Treatment Plant:

- Water filtration plants remove impurities and improve water quality.

- Water is used for processing and operations in industries and facilities. By installing an efficient water filtration plant they can save a lot of money.

- Moreover, a water treatment plant is also environmentally friendly.

- Filtered water also has a good impact on our health.

- Water filtration plants also protect us from disease-causing organisms.

Water Filtration Plants Frequently Asked Questions:

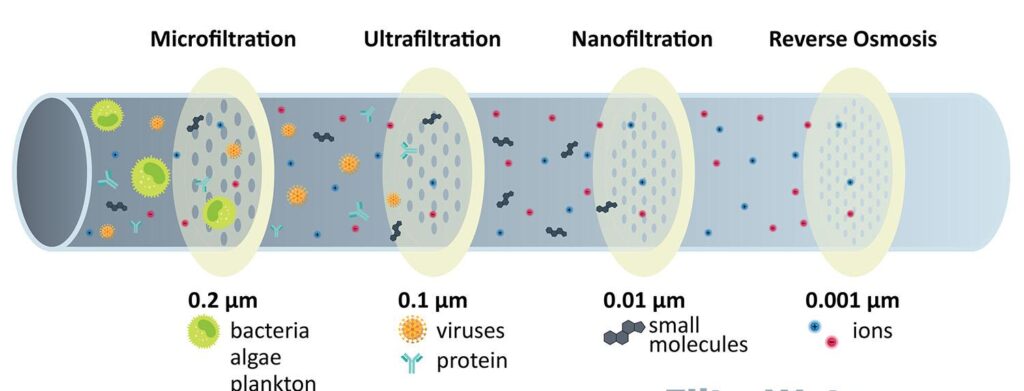

1. What makes microfiltration, ultrafiltration, and nanofiltration different from each other?

These methods of filtration relate to the media's porosity and, eventually, the type of the particulates that are being eliminated by the appropriate technology. To filter particles between 0.1 and 1.5 microns, microfiltration is commonly employed. Particles between 0.005 and 0.1 microns are generally removed by ultrafiltration using membrane separation, while nanofiltration is typically used to separate particles between 0.0001 and 0.005 microns.

2. What advantages does water filtering for industrial applications offer?

Reduced sewage production should be possible if you improve water quality that circulates through your business, which can contribute to sustainable development. Filtered water offers longer system life, decreases exposure to potentially dangerous substances, and lowers maintenance and effluent expenses.

3. Why is a water filtration system necessary?

The majority of toxins in the water at your site may be eliminated by water filtration plants. Filtration is necessary for a wide range of sectors because a spike in pollutants in the water may create rusting and fouling problems, which can reduce the efficiency of your system and eventually result in damage that can be very expensive to fix. These problems have to be resolved and your equipment kept in good operating order by a water filtering system.

4. Where are commercial water filtering systems useful?

Healthcare institutions, labs, hotels, industrial plants, institutions, eateries, and other enterprises with significant water consumption that require enhanced water quality commonly employ commercial water filtration systems to suit their high-volume water treatment demands.

5. Where can I purchase water filtering systems?

The finest place to find commercial water filtration systems is Waterman Engineers Australia, and we have a long history of effectively satisfying our clients' needs. We provide our customers the highest quality water filtration systems, and our products are well-liked because they are powerful, energy-efficient, and perform above and beyond expectations.

6. What does a water filtration plant do?

The plant filter out any undesired suspended solids, turbidity, undissolved salts, silica. This facility aims to provide clean water in business, corporate and other industries. The water filtration plant helps in filtering water so that it is suitable for human consumption.

7. What are the benefits a water filtration plant has to offer?

- It works without chemicals and pollutants

- It has a very low carbon footprint

- It provides easy operation and low energy cost

- It provides high-quality effluent with turbidity output water less than or equal to 0.2 NTU

- It is totally environment friendly

8. How does the water filtration plant work?

With the use of sand filter, carbon filter, micro filters, ultra filters, nano filters, impure water is being passed through to filter out suspended solid, turbidity and colour of water.

9. What should be considered while purchasing a water filtration system?

The first thing to be considered is the performance of the water filtration system as per the needs. The second thing to be considered is how much maintenance is involved. The next thing to be considered is how to get the required filtered water at its finest and the budget involved. Also, the latest technology can be considered when choosing to invest in a water filtration system.

10. Why should one choose Waterman Engineers Australia for industrial water filtration needs?

Waterman Australia has a team of professionals who design the water filtration system in such a way that it cleanses even the most complex compounds and imparts a high nutrient value to various processes involved. Also, it is the most efficient and best solution that can save our clients time and money.

11. What is sand filter?

It is the first stage in water filtration plant in which the solid particles like sand, dust and other impurities are removed. Three types of sand filters are typically used, rapid sand filters, upward flow sand filters and slow sand filters.

12. Use of sand filter for water, wastewater treatment

A sand filter can be used as a pre-treatment, side stream filtration, or polishing filter in many stages of water management. A sand filter frequently produces effluent that can be reused. Sand Filters for effluent treatment are used to filter wastewater by promoting the development of a biological activity that breaks down organic matter.

13. What is carbon filter?

Carbon Filter works on the principle of adsorption, in which pollutants in the fluid to be treated are trapped inside the pore structure of a carbon substrate. The substrate is made of many carbon granules, each of which is itself highly porous.

14. Use of carbon filter in water, effluent treatment plant

In water treatment, carbon filters are used to eliminate pollutants and toxins. A carbon filter aids in the removal of pollutants and impurities from water. It is the most reliable method of obtaining excellent water that is free of particulates and microbiological contaminants.

15. What is micron filtration?

Microfiltration is the process of physically removing suspended solids from water, usually through a membrane. Unlike nanofiltration and reverse osmosis, microfiltration only utilizes physical filtration to remove particles in the 0.1-to-10-micron range, including bacteria but it does not remove dissolved contaminants that nanofiltration and RO do.

16. Use of micron filtration in water and wastewater treatment

In water and wastewater treatment, in order to filter particles between 0.1 and 1.5 microns, micro filtration is commonly employed. The most prominent use of microfiltration membranes pertains to the treatment of potable water supplies. The use of MF membranes presents a physical means of separation as opposed to a chemical alternative.

On the other hand, the MF membranes are used in secondary wastewater effluents to remove turbidity but also to provide treatment for disinfection.

17. What is ultrafiltration?

Ultrafiltration is a water purification process in which water is forced through a semipermeable membrane. Suspended solids and higher molecular weight solutes remain on one side of the membrane, the retained side, while water and low molecular weight solutes filter through the membrane to the permeate side.

18. Principle of ultrafiltration

Ultrafiltration is a variety of membrane filtration in which hydrostatic pressure forces a liquid against a semi permeable membrane. Suspended solids and solutes of high molecular weight are retained, while water and low molecular weight solutes pass through the membrane.

19. Use of ultrafiltration in water wastewater

Ultrafiltration is used to remove essentially all colloidal particles (0.01 to 1 microns) from water and some of the largest dissolved contaminants. The pore size in a UF membrane is mainly responsible for determining the type and size of contaminants removed.

20. What is nanofiltration?

Nanofiltration is a membrane liquid-separation technology sharing many characteristics with reverse osmosis. Unlike RO, which has high rejection of virtually all dissolved solutes, NF provides high rejection of multivalent ions, such as calcium, and low rejection of monovalent ions, such as chloride.

21. Principle of nanofiltration

Nanofiltration is a pressure- driven membrane process that lies between ultrafiltration and reverse osmosis in terms of its ability to reject molecular or ionic species. A hydrostatic pressure is applied to transport a molecular mixture to the surface of a membrane.

Nanofiltration membranes have pore sizes between 0.5 and 2nm, which correspond to a molecular weight cut-off value of about 400-500 Da.

22 Use of nanofiltration in water wastewater

Nanofiltration is often used to filter water with low amounts of total dissolved solids, to remove organic matter and soften water. The nanofiltration technique is based on two separation mechanisms, separation under the effect of electrical repulsion for charged species, and separation under the effect of size for uncharged solutes.

23. How turbidity affects water purity?

The clarity of water is determined by the measurement of Turbidity. The greater the amount of total suspended solids (TSS) in the water, the murkier it appears and higher the measured turbidity. The suspended particles absorb heat from the sunlight, making turbid waters become warmer, and so reducing the conc. of oxygen in the water, which cause the death of some organisms and deteriorate the water aesthetics.

24. How suspended solids affects water purity?

High total suspended solids in drinking water can have both environmental effects and effects on human health. When it comes to water quality, high TSS may decrease water’s natural dissolved oxygen levels and increase water temperature.

25. How turbidity affects waste water?

A high turbidity means that there are a lot of minuscule particles in the water. A low turbidity suggests the water contains few particles, ensuring its cleanliness. As with industrial wastewater and the efforts of meeting discharge permit regulations or reuse, treatment processes strive for a low turbidity.

26. How suspended solids affects wastewater?

The measurement of suspended solids is one way of gauging water quality. Suspended solids are common in wastewater applications and should not be mistaken for settleable solids. When suspended solids are left untreated, these can contribute to sewer pipe blockage and cause damage to other systems.