WASTEWATER SLUDGE TREATMENT PLANTS

Wastewater sludge treatment plants are facilities designed to treat the sludge generated during the wastewater treatment process. When wastewater is treated, a semi-solid material called sludge is created, and it has a high level of organic materials and pathogens.

There are several methods used to treat sludge in wastewater treatment plants, including:

1. Anaerobic digestion:

This process involves using microorganisms to break down the organic matter in the sludge in the absence of oxygen. The end product of anaerobic digestion is biogas, which can be used as a source of energy.

2. Aerobic digestion:

This process involves introducing air into the sludge to encourage the growth of aerobic microorganisms. These microorganisms break down the organic matter in the sludge, reducing its volume and stabilizing it.

3. Composting:

To make a mixture that can be used as fertiliser, the sludge is combined with organic resources like leaves, grass, and wood chips.

4. Dewatering:

This process involves removing the water from the sludge to reduce its volume and make it easier to handle and transport.

5. Incineration:

This process involves burning the sludge at high temperatures to reduce its volume and destroy any pathogens present. The end product is ash, which can be disposed of in a landfill.

6. Land Application:

This process involves applying the sludge to land as a fertilizer. This method is regulated to ensure that the sludge does not contain any harmful pathogens or chemicals.

wastewater sludge treatment plants play a crucial role in managing the waste generated during the wastewater treatment process, ensuring that it is safely and effectively treated before disposal.

Dewatering Detail in Sludge Treatment Plants

Dewatering is an essential step in the treatment of wastewater sludge. This process involves removing water from the sludge to reduce its volume and make it easier to handle and transport. There are several methods used for dewatering wastewater sludge, including:

1. Filter press:

This process involves passing the sludge between two belts under pressure to squeeze out the water. The resulting cake is then removed from the belts and disposed of.

2. Centrifuge:

This process involves spinning the sludge in a centrifuge at high speed to separate the solids from the liquid. The resulting cake is then removed and disposed of.

3. Screw press:

This process involves passing the sludge through a series of screws that apply pressure to squeeze out the water. The resulting cake is then removed and disposed of.

4. Plate and frame press:

This process involves passing the sludge between a series of plates and frames under pressure to squeeze out the water. The resulting cake is then removed and disposed of.

5. Vacuum filter

This process involves passing the sludge through a vacuum filter to remove the water. The resulting cake is then removed and disposed of.

The choice of dewatering method depends on the characteristics of the sludge, the volume to be processed, and the available equipment. Dewatering can reduce the volume of sludge by up to 80%, making it easier to transport and dispose of. The resulting cake can be sent to a landfill, incinerated, or used as a fertilizer, depending on the regulations and the treatment goals of the plant.

Sludge Dewatering Equipment’s offering by Waterman Engineers Australia

(i) Filter press

(ii) Screw press

Sludge dewatering equipment is used in wastewater treatment plants to remove water from sludge, reducing its volume and making it easier to handle and dispose of. Waterman Engineers Australia offering two common types of sludge dewatering equipment are filter presses and screw presses.

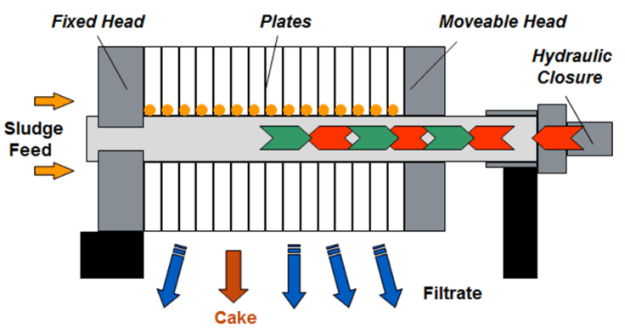

(i) Filter Press:

A filter press is a piece of equipment that uses a series of plates and frames to separate solids from liquids. The sludge is pumped into the belt filter press, where it is fed between the plates. Pressure is then applied to the plates to squeeze out the water and separate the solids. The solids are collected as a cake between the plates, and the water is discharged as filtrate. The cake can then be removed and disposed of. Filter presses can be operated manually or automatically, depending on the size and complexity of the unit.

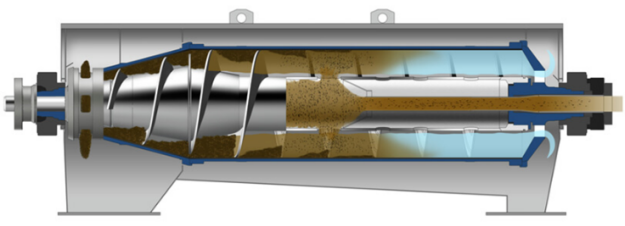

(ii) Screw Press:

A screw press is a type of equipment that uses a series of rotating screws to remove water from sludge. The sludge is fed into the screw press, where it is compressed by the screws against a screen. The water is forced out through the screen, and the solids are collected as a cake that is discharged at the end of the screw press. Screw presses are available in different sizes and designs, and can be used for a range of sludge types.

Advantage

Both filter presses and screw presses that are offering Waterman Engineers Australia have their advantages. Filter presses are generally more effective at separating solids from liquids, and they require less maintenance and have a low operating cost. Screw presses are simpler to operate and require less maintenance, and they may be as effective for sludge with high water content. The choice of sludge dewatering equipment depends on the characteristics of the sludge, the volume to be processed, and the available equipment and resources.

Waterman Engineers Australia is a leading sludge dewatering equipment provider, offering a wide range of options for your needs. As a reputable belt filter press manufacturer, we understand the importance of effective solid-liquid separation. Our filter presses are known for their high efficiency and low operating costs. On the other hand, as a screw press manufacturer, we also recognize the advantages of screw presses in certain situations. Screw presses are ideal for sludge with high water content and are easier to operate, making them a popular choice for many customers. Ultimately, the choice between a filter press or a screw press will depend on the specific characteristics of your sludge, the volume to be processed, and the resources available to you. Regardless of your needs, Waterman Engineers Australia has the expertise and experience to guide you through the process of selecting the right sludge dewatering equipment.

Sludge Drying During Sludge Treatment

Sludge drying is an important process in the treatment of wastewater sludge. The primary purpose of sludge drying is to reduce the volume and weight of the sludge, making it easier and more cost-effective to handle and dispose of. There are several methods used for sludge drying, including:

1. Thermal Drying:

This method involves heating the sludge to evaporate the water. The dried sludge is then collected and disposed of. Thermal drying can be done using direct or indirect heat, and the temperature and time of drying can vary depending on the characteristics of the sludge.

2. Solar Drying:

This method involves spreading the sludge on a large surface area in the open air, where it is exposed to sunlight and wind. The water in the sludge evaporates, and the dried sludge is then collected and disposed of. Solar drying is a low-cost and environmentally friendly method, but it requires large areas of land and may not be suitable for areas with limited sunlight or rain.

3. Mechanical Drying:

This method involves using mechanical equipment such as drum dryers, fluidized bed dryers, and spray dryers to remove the water from the sludge. The dried sludge is then collected and disposed of. Mechanical drying is a faster and more efficient method than thermal or solar drying, but it requires more energy and may be more expensive to operate.

The choice of sludge drying method depends on several factors, including the characteristics of the sludge, the volume to be processed, and the available equipment and resources. Drying can reduce the volume and weight of sludge by up to 90%, making it easier to handle and dispose of. The dried sludge can be sent to a landfill, incinerated, or used as a fertilizer, depending on the regulations and the treatment goals of the plant. Proper sludge drying and disposal are essential for protecting public health and the environment.

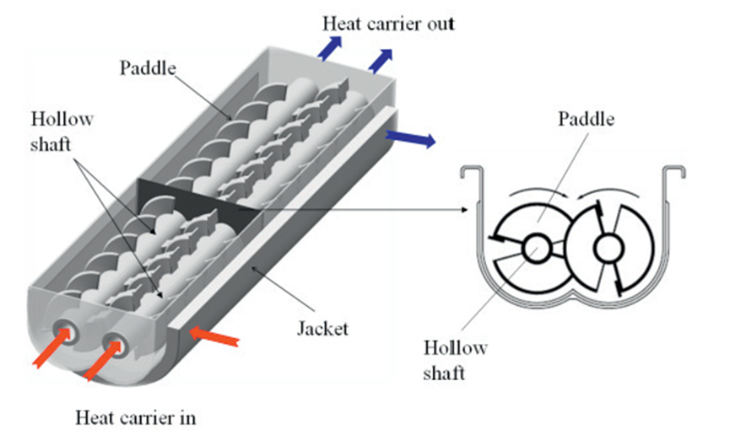

Waterman Engineers Australia Paddle dryer for sludge drying

As a leading paddle dryer manufacturer, exporter, and supplier, Waterman Engineers Australia understands the importance of efficient wastewater sludge treatment. Our paddle dryers are designed to remove moisture from sludge quickly and effectively. The paddles in our paddle dryers are specially designed to provide maximum agitation, ensuring that the sludge is evenly mixed with the heated surfaces. This prevents lumps or clumps from forming and ensures a uniform drying process. We take great pride in our reputation as a paddle dryer exporter and supplier, and our clients trust us to provide high-quality equipment that meets their needs. Whether you are looking for a standalone paddle dryer or a complete sludge treatment system, Waterman Engineers Australia has the expertise and experience to guide you through the process. Contact us today to learn more about our paddle dryers and other sludge treatment solutions.

The paddle dryer consists of a large, cylindrical vessel that is fitted with a series of rotating paddles. The sludge is fed into the dryer through an inlet, where it comes into contact with the heated paddles. As the sludge moves through the dryer, the moisture evaporates, and the dried sludge is discharged through an outlet. The dried sludge can then be collected and disposed of.

Paddle dryers are known for their high efficiency and energy-saving performance. The continuous mixing and agitation of the sludge in the dryer ensure that all parts of the sludge are exposed to the heated surfaces, maximizing the drying rate. The dryer also operates at low temperatures, reducing the risk of thermal damage to the sludge.

In addition to their efficiency, paddle dryers are also easy to operate and maintain. The simple design of the dryer and the absence of complex mechanisms make it easy to clean and inspect. The dryer can also be customized to meet specific requirements, such as sludge composition, moisture content, and capacity.

Overall, paddle dryers that are offering Waterman Engineers Australia are an effective and efficient method for drying wastewater sludge. They offer a reliable and cost-effective solution for reducing sludge volume and weight, making it easier to handle and dispose of. With their high efficiency, energy-saving performance, and ease of operation and maintenance, paddle dryers are a popular choice for sludge drying in wastewater treatment plants.

Wastewater Sludge Treatment Plants Frequently Asked Questions:

Filter Press for Sludge Dewatering - Frequently Asked Questions

What is a filter press and how does it work?

A filter press is a mechanical device used for solid-liquid separation by pressure filtration. It consists of a series of plates with a filter cloth and a pump that feeds the slurry into the press. As pressure is applied, the liquid is forced through the filter cloth, leaving the solid material behind.

What is sludge dewatering and why is it important?

Sludge dewatering is the process of removing water from sludge, which is a by-product of wastewater treatment. It is important because it reduces the volume and weight of the sludge, making it easier and less expensive to transport and dispose of.

What are the different types of filter presses used for sludge dewatering?

There are several types of filter presses, including recessed plate, membrane, and plate and frame. The choice of filter press depends on the characteristics of the sludge and the specific dewatering requirements.

What are the advantages of using a filter press for sludge dewatering?

Some of the advantages of using a filter press for sludge dewatering include high efficiency, low operating cost, and the ability to handle high solids concentrations.

What are the limitations of using a filter press for sludge dewatering?

Some of the limitations of using a filter press include the need for regular maintenance, the potential for clogging, and the difficulty of handling certain types of sludge.

What is the typical cycle time for a filter press used for sludge dewatering?

The cycle time for a filter press depends on the specific model and the characteristics of the sludge, but it typically ranges from 1 to 4 hours.

How do you select the appropriate filter cloth for a filter press used for sludge dewatering?

The selection of filter cloth depends on the characteristics of the sludge, such as particle size and chemical composition. Factors such as fabric weave, thread count, and pore size also play a role in the selection process.

How do you optimize the performance of a filter press used for sludge dewatering?

To optimize the performance of a filter press, it is important to properly size the press for the sludge characteristics, maintain the equipment, and use the appropriate filter cloth. Operating parameters such as pressure, flow rate, and cycle time should also be optimized.

How do you clean a filter press after sludge dewatering?

To clean a filter press, the plates and filter cloths should be removed and washed with a high-pressure water jet or other cleaning solution. The press should be inspected for any damage or wear, and any necessary repairs should be made.

What are the safety considerations when using a filter press for sludge dewatering?

Some of the safety considerations when using a filter press include proper training for operators, the use of appropriate personal protective equipment, and adherence to all safety protocols and guidelines.

Screw Press Used for Sludge Dewatering - Frequently Asked Questions

How does a screw press work?

A screw press works by feeding sludge into a cylindrical screen chamber. Inside the chamber, a slowly rotating screw applies pressure to the sludge, forcing water through the screen and out of the press. The dewatered sludge is then discharged from the end of the press.

What are the benefits of using a screw press for sludge dewatering?

Screw presses are efficient, reliable, and require minimal maintenance. They can dewater sludge to a high degree and produce a drier, more compact sludge cake.

What types of sludge can be dewatered using a screw press?

Screw presses can be used to dewater a variety of sludge types, including wastewater sludge, industrial sludge, and food processing waste.

What is the capacity of a screw press for sludge dewatering?

The size of the apparatus and the kind of sludge being dewatered affect a screw press's capacity. Generally, screw presses can handle anywhere from a few gallons to several hundred gallons of sludge per minute.

What is the dewatering efficiency of a screw press?

The dewatering efficiency of a screw press can range from 60% to 90%, depending on the type of sludge being dewatered and the operating conditions of the press.

How much energy does a screw press use?

The amount of energy used by a screw press varies depending on the size of the equipment and the dewatering capacity. Generally, screw presses are energy-efficient and consume less power than other types of dewatering equipment.

What is the maintenance required for a screw press?

Screw presses require minimal maintenance, such as cleaning the screen and lubricating the bearings. Regular maintenance can help ensure optimal performance and prevent equipment breakdowns.

What are the operating costs of a screw press?

The operating costs of a screw press include energy costs, maintenance costs, and labor costs. However, the low maintenance requirements and energy efficiency of screw presses can result in lower operating costs compared to other types of dewatering equipment.

How long does a screw press last?

The lifespan of a screw press can vary depending on the quality of the equipment and the operating conditions. With proper maintenance and care, a screw press can last for many years.

What advantages does sludge dewatering with a screw press provide for the environment?

The amount of sludge that needs to be transported and disposed of can be decreased by using a screw press for sludge dewatering, which lowers the cost of transportation and disposal and lessens the environmental effect.

Can a screw press be used for other applications besides sludge dewatering?

Screw presses can be used for other applications besides sludge dewatering, such as juice extraction, oil extraction, and wastewater treatment.

What safety precautions should be taken when operating a screw press?

Operators should wear appropriate protective gear, such as gloves and safety glasses, and follow all safety guidelines and procedures provided by the equipment manufacturer.

What is the cost of a screw press for sludge dewatering?

The cost of a screw press for sludge dewatering varies depending on the size of the equipment and the manufacturer. Generally, screw presses are more expensive than other types of dewatering equipment but can provide a high return on investment over time.

Paddle Dryer for Sludge Drying - Frequently Asked Questions

What is a paddle dryer?

A paddle dryer is a type of indirect dryer used for drying sludge. It features a slowly rotating, agitated drum that heats and dries sludge as it passes through the dryer.

How does a paddle dryer work?

A paddle dryer uses a slowly rotating, agitated drum to heat and dry sludge. The sludge is fed into the dryer, where it is heated by the drum and agitated by the paddles. As it passes through the dryer, the sludge loses moisture and becomes dry solids.

What are the advantages of using a paddle dryer for sludge drying?

Paddle dryers offer several advantages over other drying methods, including high thermal efficiency, low operating costs, and a compact footprint. They also produce a dry, free-flowing product that is easy to handle and dispose of.

What types of sludge can be dried using a paddle dryer?

Paddle dryers are suitable for drying a wide range of sludge types, including municipal, industrial, and agricultural sludge. They can also be used to dry sewage sludge, wastewater sludge, and other types of organic sludge.

What is the capacity range of a paddle dryer?

The capacity range of a paddle dryer depends on the size of the drum and the speed of rotation. Paddle dryers can typically handle sludge volumes ranging from a few hundred liters to several thousand liters per hour.

How long does it take to dry sludge using a paddle dryer?

The amount of moisture in the sludge, the dryer's temperature, and the rotational speed all affect how quickly it dries when using a paddle dryer. In general, sludge can be dried in a paddle dryer in a few hours to a few days.

What is the energy source for a paddle dryer?

Paddle dryers can be heated using a variety of energy sources, including steam, hot water, or thermal oil. The choice of energy source depends on the specific requirements of the application.

What are the maintenance requirements for a paddle dryer?

Paddle dryers require minimal maintenance, as they have no moving parts aside from the drum and paddles. Regular cleaning and inspection of the dryer and its components are necessary to ensure optimal performance and longevity.

What are the safety considerations when using a paddle dryer?

Safety considerations when using a paddle dryer include the risk of burns from the hot drum or paddles, as well as the risk of fire or explosion from combustible dust. Proper ventilation and dust control measures are essential to minimize these risks.

What are the environmental considerations when using a paddle dryer?

Environmental considerations when using a paddle dryer include the emission of greenhouse gases and other pollutants from the energy source used to heat the dryer. These emissions can be decreased by utilising energy-efficient devices and renewable energy sources.

Can a paddle dryer be used for other applications besides sludge drying?

Paddle dryers can be used for other applications besides sludge drying, including drying powders, granules, and other materials. They are particularly well-suited for drying materials that are sticky or have a tendency to agglomerate.

What is the cost of a paddle dryer?

The size of the dryer, the building materials, and the particular needs of the application are some of the variables that affect the price of a paddle dryer. Paddle dryers can range in price from a few thousand dollars to several hundred thousand dollars.

What are the installation requirements for a paddle dryer?

Installation requirements for a paddle dryer include a level foundation, proper ventilation and dust control measures, and access to the energy source and sludge feed system. Proper installation is critical to ensuring optimal performance and longevity of the dryer.