Before they are released into the atmosphere, industrial exhaust gases are cleaned by scrubbers, which are air pollution control systems. They are frequently employed in industrial operations that release gases including sulphur dioxide, nitrogen oxides, and particulate matter, all of which are dangerous to the environment and to people's health.

Scrubbers come in a variety of forms, such as wet scrubbers, dry scrubbers, and electrostatic precipitators. The most common kind of scrubbers are known as wet scrubbers, and they function by spraying a liquid solution over the exhaust gas stream, which subsequently traps and removes the pollutants from the gas.

In contrast, dry scrubbers use a solid substance to either absorb or react with the contaminants in the gas stream. Pollutants are charged and collected by electrostatic precipitators, which then eliminate them from the gas stream.

Scrubbers are utilised in many different industries, including as metal processing, chemical manufacture, and power generating etc. They can aid in lowering emissions of pollutants including particulate matter and sulfur dioxide, which can both contribute to acid rain and cause respiratory issues.

Scrubbers can be successful at removing pollutants from industrial exhaust gases, but doing so can produce trash that needs to be disposed of correctly. Scrubbers also require energy to run.

Scrubbers are a crucial instrument in the fight against air pollution, but to ensure that emissions are reduced to the absolute minimum, they should be used in conjunction with other strategies like pollution prevention and source reduction.

How to Select The Right Scrubber based on Applications and Advantages?

1. FLUE GAS DESULFURIZATION (FGD) SCRUBBER Desulfurization of flue gases

FGD, commonly known as a wet scrubber, is a form of air pollution management device used to remove sulphur dioxide (SO2) from industrial process and power plant exhaust flue gases. Sulfur dioxide, a hazardous gas, produced by the combustion of coal and oil, it contributes to acid rain and other environmental hazards as well.

The FGD process involves spraying a liquid solution, usually a mixture of water and limestone or lime, into the flue gas stream. The solution reacts with the sulfur dioxide in the gas stream, forming a solid compound that can be collected and disposed of. The FGD equipment typically consists of a scrubbing tower or vessel, a recirculation system for the liquid solution, and a solid handling system for the by-products.

There are several types of FGD systems, including spray tower, venturi scrubber, and packed bed scrubber systems. Each system has its own unique advantages and disadvantages, depending on the specific application and operating conditions.

One of the main advantages of FGD equipment is its effectiveness in removing sulfur dioxide from flue gas streams. With proper design and operation, FGD systems can remove up to 99% of the sulfur dioxide emissions from power plants and industrial processes. This can significantly reduce the environmental impact of these operations and help to meet regulatory requirements.

Another advantage of FGD equipment is its ability to produce useful by-products. The solid compounds formed during the FGD process, such as gypsum and calcium sulfite, can be sold or reused in other applications, such as cement manufacturing and agriculture. This can provide a cost savings and environmental benefit for the facility.

However, there are some disadvantages to FGD equipment. The expense of installation and operation is one of the most significant challenges. To function properly, FGD systems necessitate a large capital investment as well as continual maintenance. The liquid solution used in the process can be costly as well, and the solids handling system must be carefully managed to avoid environmental issues.

One type of Flue gas desulfurization is given below.

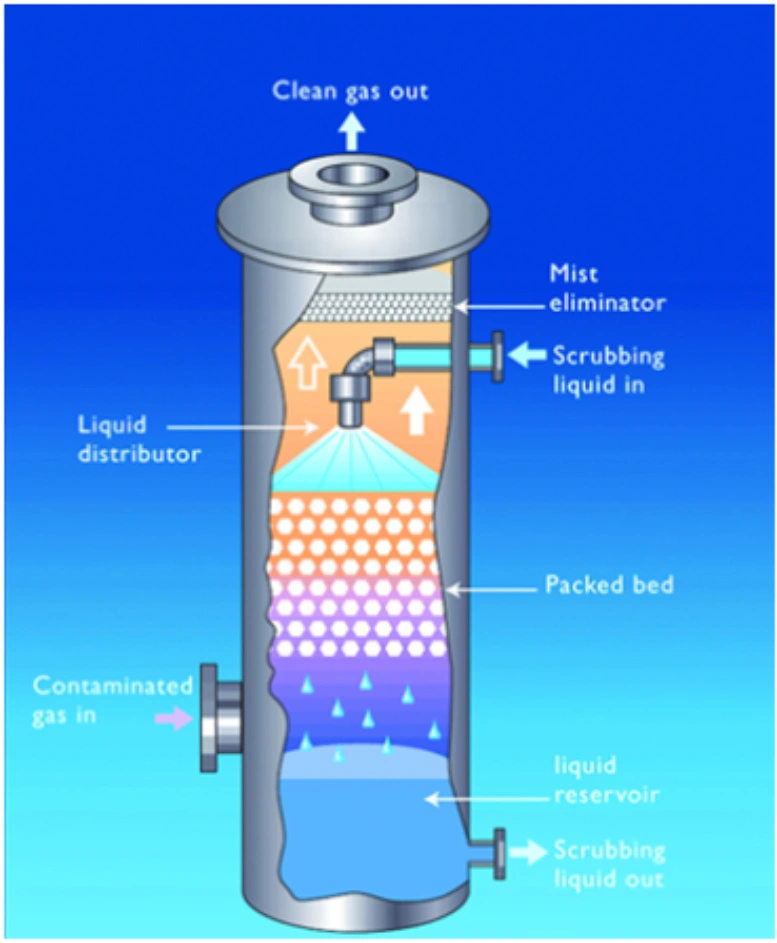

a) Packed Tower Gas Scrubber:

Tower Gas in Packing In scrubbers, a tower of packing material is used to increase the surface area of the gas-liquid contact region. As the gas stream moves through the tower, the liquid stream that removes contaminants interacts with it. By entering through tower the intake near the bottom and moving through the support plate and packed bed in the opposite direction as the scrubbing liquid flow, gas eliminates contaminants. After passing through the packed bed, the cleaned gas continues its journey towards the top of the tower through a mist eliminator section. In this case, any entrained liquid is removed before the pure air is released through the exit. These types of scrubbers work best when the gases being handled are clear of particles, as these have a tendency to clog the packing.

Advantages:

Packed Tower Gas Scrubbers are effective at removing a wide range of pollutants, including particulate matter, acid gases, and organic compounds.

Application:

Packed Tower Gas Scrubbers are commonly used in industries such as chemical manufacturing, pharmaceuticals, and wastewater treatment

2. Packaged Scrubber:

Packaged Scrubbers are compact air pollution control systems that combine several different air pollution control technologies into a single unit. They typically consist of a wet scrubber, followed by a mist eliminator and a fan.

Advantages:

Packaged Scrubbers are compact and easy to install and can be used to control a wide range of air pollutants. They are particularly effective at removing particulate matter and acid gases.

Application:

Industries like food processing, pharmaceuticals, wastewater treatment, and water-soluble VOC cleaning all frequently employ packaged scrubbers to remove chlorine, HCI, ammonia, and SO2 or H2S.

3. WET Electrostatic Precipitators:

An electrostatic precipitator known as a WET Electrostatic Precipitator (ESP) removes contaminants from gas streams by using a liquid medium. A high voltage electrode is used to charge the pollutants in the gas stream, which attracts them to the liquid medium. In an ESP chamber, contaminated air is drawn in and ionised by electron emitting electrodes. The electron field charges the suspended particles, which then move to a collection plate. Rapping or beating the collection plates with rappers periodically removes accumulated particle matter from the plates. Heavy particles fall to the ESP's base where they are collected in hoppers for disposal.

Advantages:

WET ESPs are effective at removing a wide range of pollutants, including fine particulate matter and acid gases. They are also relatively easy to operate and maintain.

Application:

WET ESPs are commonly used in industries such as power generation, cement manufacturing, and metal processing.

4. Kitchen Exhaust Scrubber:

Kitchen Exhaust Scrubbers are used to remove grease, smoke, and other pollutants from commercial kitchen exhausts. To clean up the gas stream, they often employ a wet scrubbing method. Pollutants are drawn into a liquid mist that is passed through a gas stream.

Advantages:

Kitchen Exhaust Scrubbers are effective at removing grease and smoke from commercial kitchen exhausts. They can also improve air quality in the surrounding area.

Application:

Kitchen Exhaust Scrubbers are commonly used in commercial kitchens, such as those found in restaurants, hospitals, and schools.

5. Boiler Wet Scrubbers:

Boiler Wet Scrubbers are used to remove pollutants such as sulfur dioxide and nitrogen oxides from boiler emissions. These contaminants are frequently chemical substances like ammonia, chlorine, or sulfur compounds. To clean up the gas stream, they often employ a wet scrubbing method. A liquid mist is used to pass through the gas stream, reacting with the contaminants to eliminate them.

Advantages:

Boiler Wet Scrubbers are effective at removing a wide range of pollutants from boiler emissions. They can also help to improve boiler efficiency and reduce fuel costs.

Application:

Boiler Wet Scrubbers are commonly used in industries such as power generation, chemical manufacturing, and paper and pulp production

6. Scrubber for Jet Venturi Fumes:

The Jet Venturi Fume Scrubber is a type of wet scrubber that sucks in the gas stream to be treated by creating a vacuum with a high-velocity water stream. The gas stream is then accelerated and combined with the water stream after being driven via a Venturi throat. As a result, there is extensive contact between the gas and liquid, which effectively removes contaminants.

Advantages:

Jet Venturi Fume Scrubbers can manage a wide range of gas flow rates and pollutant concentrations and are relatively simple and straightforward to operate. They are particularly good in eliminating acid gases and particle materials.

Application:

Jet Venturi Fume Scrubbers are commonly used in industries such as chemical manufacturing, pharmaceuticals, and metal processing.

7. Vent Gas Scrubber System:

Vent Gas Scrubber Systems are used to remove pollutants from gas streams that are vented from storage tanks, reactors, and other equipment. To clean up the gas stream, they use a combination of wet scrubbing and gravity separation.

Advantages:

Particulate matter, sulphur dioxide, and nitrogen oxides are just a few of the contaminants that Vent Gas Scrubber Systems are good at getting rid of. They are also rather easy to understand and use.

Application:

Vent Gas Scrubber Systems are commonly used in industries such as oil and gas, chemical manufacturing, and petrochemicals.

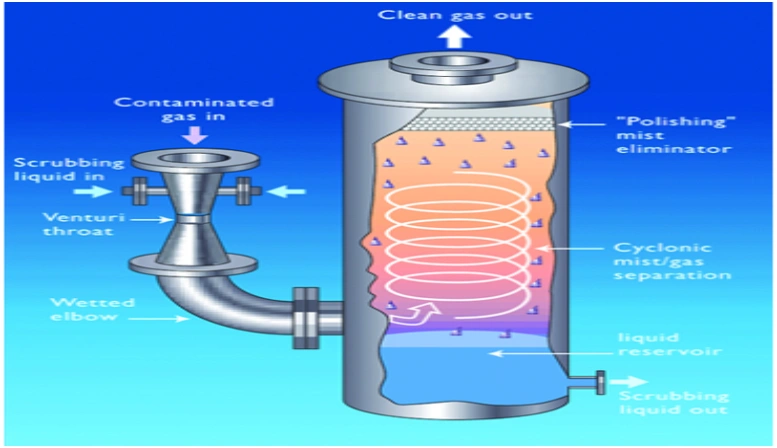

8. High Energy Venturi Scrubber System:

High Energy Venture Scrubber Systems, which combine a High Energy Venture Scrubber and a Cyclon Separator, are intended to remove fine micron and submicron material from industrial and commercial effluent gases. These scrubbers are efficient at removing a wide range of air pollutants, including dust, fumes, vapours, and mists. Because there is so much contact between the gas and the liquid because of the turbulence, pollutants can be removed effectively.

Advantages:

High Energy Venturi Scrubber Systems are particularly effective at removing fine particulate matter and other pollutants such as sulfur dioxide and nitrogen oxides.

Application:

High Energy Venturi Scrubber Systems are commonly used in industries such as power generation, cement manufacturing, and steel production.

9. Fume Scrubber:

Fume Scrubbers are used to remove harmful fumes and gases from industrial processes. They typically use a wet scrubbing system to remove pollutants from the gas stream.

Advantages:

Fume Scrubbers are effective at removing a wide range of pollutants, including corrosive gases and acid mists. They can also help to improve workplace safety and air quality.

Application:

Fume Scrubbers are commonly used in industries such as metal processing, chemical manufacturing, and pharmaceuticals.

10. Foundry Wet Scrubbers:

Foundry Wet Scrubbers are used to remove pollutants such as particulate matter and volatile organic compounds from foundry emissions. To clean up the gas stream, they often employ a wet scrubbing method.

Advantages:

Foundry Wet Scrubbers are effective at removing a wide range of pollutants from foundry emissions. They can also help to improve workplace safety and air quality.

Application:

Foundry Wet Scrubbers are commonly used in industries such as metal casting, aluminum production, and iron and steel manufacturing.

11. Food Industries Wet Scrubber:

Food Industries Wet Scrubbers are used to remove pollutants such as odours, smoke, and grease from food processing emissions. They typically use a wet scrubbing system to remove pollutants from the gas stream.

Advantages:

Food Industries Wet Scrubbers are effective at removing a wide range of pollutants from food processing emissions. They can also help to improve workplace safety and air quality.

Application:

Food Industries Wet Scrubbers are commonly used in food processing facilities, such as those that produce baked goods, meat products, and dairy products.

12. Chemical Factory Wet Scrubber:

Chemical Factory Wet Scrubbers are used to remove pollutants such as acid gases, particulate matter, and volatile organic compounds from chemical manufacturing emissions. They typically use a wet scrubbing system to remove pollutants from the gas stream.

Advantages:

Chemical Factory Wet Scrubbers are effective at removing a wide range of pollutants from chemical manufacturing emissions. They can also help to improve workplace safety and air quality.

Application:

Chemical Factory Wet Scrubbers are commonly used in industries such as pharmaceuticals, petrochemicals, and plastics manufacturing.

13. Generator Wet Scrubber:

Generator Pollutants including nitrogen oxides and sulfur dioxide are removed from diesel generator exhaust using wet scrubbers. NOX, HC, CO, and PM, which includes any observable smoke and soot, are among the exhaust emissions from diesel-powered generators. Our dust collector technology completely captures the pollutants in the exhaust flow and emits only clean air. To clean up the gas stream, they often employ a wet scrubbing method.

Advantages:

Generator Wet Scrubbers are effective at removing a wide range of pollutants from diesel generator emissions. They can also help to improve air quality and reduce environmental impacts.

Application:

Generator Wet Scrubbers are commonly used in industries such as power generation, data centers, and backup power systems.

FGD & Venturi Scrubbers Frequently Asked Questions

Q. What is an FGD scrubber for air pollution control?

A. An FGD scrubber, also known as a Flue Gas Desulfurization scrubber, is a device used to remove sulfur dioxide (SO2) from flue gases emitted by industrial processes or power plants.

Q. How does an FGD scrubber work to control air pollution?

A. An FGD scrubber uses a chemical process to absorb sulfur dioxide from flue gases. Typically, a slurry containing a sorbent, such as a limestone or lime, is sprayed into the flue gas stream. The sorbent reacts with sulfur dioxide, forming a solid byproduct that can be disposed of safely.

Q. What are the main components of an FGD scrubber system?

A. An FGD scrubber system consists of several key components, including an absorber tower, a reagent storage and preparation system, a slurry circulation system, a mist eliminator, and a wastewater treatment system.

Q. What types of pollutants can an FGD scrubber remove?

A. FGD scrubbers are primarily designed to remove sulfur dioxide (SO2) from flue gases. However, they can also capture other pollutants such as mercury, particulate matter, and some trace metals.

Q. What are the advantages of using an FGD scrubber for air pollution control?

A. The advantages of using an FGD scrubber include the effective removal of sulfur dioxide, which helps reduce acid rain and respiratory issues. Additionally, it can capture other pollutants, improve air quality, and comply with environmental regulations.

Q. What are the environmental benefits of using Venturi scrubbers?

A. Venturi scrubbers provide environmental benefits by reducing particulate matter emissions, which can contribute to improved air quality and human health. They also aid in the removal of certain gases and odors, helping to minimize potential environmental nuisances. By controlling pollution at its source, Venturi scrubbers contribute to sustainable and responsible industrial practices.

Q. How effective are FGD scrubbers in reducing air pollution?

A. FGD scrubbers are highly effective in reducing sulfur dioxide emissions. They can achieve removal efficiencies of up to 90-99% for sulfur dioxide, depending on the design and operating conditions.

Q. Are there different types of FGD scrubbers available?

A. Yes, there are various types of FGD scrubbers, including wet scrubbers (such as limestone/gypsum and seawater scrubbers), dry scrubbers (such as spray dry and dry injection scrubbers), and electrostatic precipitators.

Q. What is a venturi scrubber for air pollution control?

A. Venturi scrubber is an air pollution control device that uses the principle of a venturi nozzle to remove pollutants from industrial exhaust gases. It is particularly effective in capturing particulate matter and some gases.

Q. How does a venturi scrubber work to control air pollution?

A. Venturi scrubber operates by creating a high-velocity gas stream through a narrow throat section, which creates a pressure drop. Polluted gases are forced through the venturi throat, where they collide with liquid droplets. The pollutants adhere to the liquid droplets, which are then separated and collected.

Q. What are the key components of a venturi scrubber system?

A. Venturi scrubber system typically includes a venturi scrubber chamber, a liquid or water injection system, a gas inlet, a mist eliminator, and a collection and disposal system for the captured pollutants.

Q. What types of pollutants can a venturi scrubber remove?

A. Venturi scrubbers are effective in removing various pollutants, including particulate matter, dust, aerosols, gases such as sulfur dioxide and hydrogen chloride, and certain volatile organic compounds (VOCs).

Q. What are the advantages of using a venturi scrubber for air pollution control?

A. Venturi scrubbers offer high collection efficiencies for particulate matter, including fine particles. They are also effective for capturing gases and certain volatile organic compounds. Venturi scrubbers have a simple design, require minimal maintenance, and can handle high gas temperatures and high particulate loadings.

Q. How effective are venturi scrubbers in reducing air pollution?

A. Venturi scrubbers can achieve high collection efficiencies for larger particles, typically above 90%. However, their efficiency for smaller particles may vary depending on factors such as particle size, inlet concentration, and operating conditions.

Q. Are Venturi scrubbers suitable for high-temperature applications?

A. Venturi scrubbers can be designed to handle high-temperature gas streams, but there are limitations. The materials of construction and thermal insulation must be carefully selected to withstand the temperature without compromising the scrubber's performance or integrity. Higher temperatures can also affect the choice of liquid used for scrubbing and may require additional heat management measures.

Q. Are there different types of venturi scrubbers available?

A. Yes, there are different types of venturi scrubbers, including single-stage venturi scrubbers, multi-stage venturi scrubbers, and high-energy venturi scrubbers. Each type has specific applications and operating principles.

Q. Can FGD scrubbers and venturi scrubbers be used together in an air pollution control system?

A. Yes, FGD scrubbers and venturi scrubbers can be used together in an air pollution control system. FGD scrubbers primarily target sulfur dioxide removal, while venturi scrubbers are effective in capturing particulate matter and certain gases. Combining these technologies can enhance overall pollutant removal efficiency.

Q. How do Venturi scrubbers compare to other air pollution control devices?

A. Venturi scrubbers have certain advantages over other air pollution control devices. Compared to electrostatic precipitators, they can handle higher gas flow rates and are more effective for removing fine particles. Compared to wet scrubbers, Venturi scrubbers have a more compact design and can handle higher gas velocities. However, the choice of the most suitable control device depends on the specific requirements of the application.

Q. What industries or applications commonly use FGD scrubbers?

A. FGD scrubbers are commonly used in industries such as power generation, coal-fired plants, oil refineries, cement production, and waste incineration, where sulfur dioxide emissions need to be controlled.

Q. What industries or applications commonly use venturi scrubbers?

A. Venturi scrubbers find applications in various industries, including metal refining, chemical processing, pulp and paper manufacturing, pharmaceuticals, food processing, and incineration plants.

Q. Are there any regulations or standards related to the use of FGD scrubbers and venturi scrubbers for air pollution control?

A. Regulations and standards regarding the use of FGD scrubbers and venturi scrubbers vary across countries and regions. Environmental agencies and regulatory bodies typically set emission limits and guidelines for air pollution control technologies, including scrubbers, to ensure compliance with air quality standards and environmental protection. It is important for industries to adhere to these regulations and standards when implementing scrubber systems.

Q. Can Venturi scrubbers be used for removing heavy metals from emissions?

A. Venturi scrubbers are primarily designed for particulate matter removal and may have limited effectiveness in removing heavy metals from emissions. For the efficient removal of heavy metals, specialized control technologies such as wet scrubbers with specific chemical reagents or electrostatic precipitators with high-efficiency collection plates are often employed.