Reverse Osmosis Plant Details:

A reverse osmosis plant is a manufacturing plant, where water is purified and desalinated by forcing water through a membrane, typically known as a reverse osmosis process. Water produced by plant RO may be used for several purposes like desalination, wastewater treatment, and the reclamation of dissolved minerals.

RO Plant Description

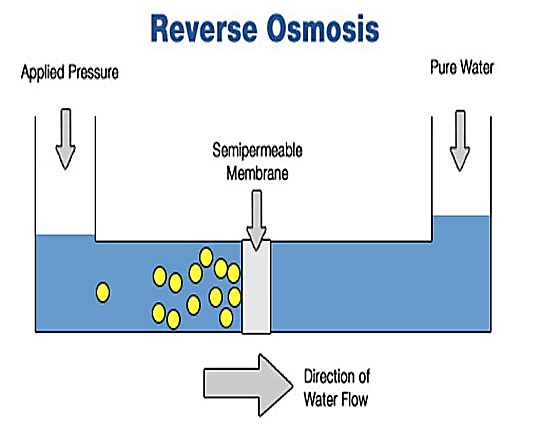

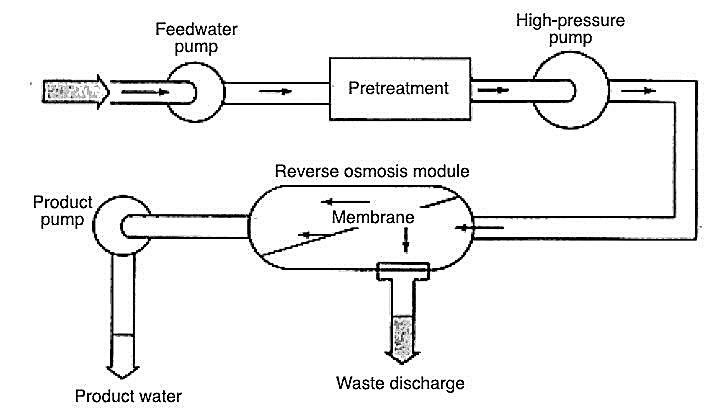

An average drinking water RO plant system requires six KW hours of electricity to desalinate one cubic meter of water. Reverse osmosis water plants requires a variety of pre-treatment techniques including softening, DE chlorination, and anti-scale treatment. Following pre-treatment, high levels of pressure send water through a semi-permeable membrane, which holds all contaminants except water.

Working Principle of RO Plants

RO Plant or Reverse Osmosis Systems is working by using a high-pressure pump to increase the pressure on the salt side of the RO and force the water across the semipermeable RO membrane, leaving almost all of the dissolved salts left in the reject stream. This concludes the ro plant working principle.

RO Plant Design

To enhance the efficiency and life of the Reverse Osmosis plant, effective pretreatment of the feed water is required. Selection of the right pretreatment will maximize efficiency and membrane life by reducing:

- Fouling

- Scaling

- Membrane Degradation

RO plant design is consisting of:

Determining pretreatment requirement of Reverse Osmosis Plant

If the feed water has traces of heavy metals, it is highly recommended to dose some chlorine to change the dissolved heavy metals to physical form, the media filter will filter most of it in a ro water purifier plant.

Reverse Osmosis Plant Selection of membrane

Membrane elements are an important part of RO plants. The proteins (mostly polyamide) that makeup membrane elements vary depending on the ending clarity and intake water seawater or brackish water etc.

RO Plant System Configuration

The conventionally following configuration is applied for the effective working of RO plant:

- Pre-Chlorination Dosing System

- Raw Water Storage Tank

- Feed Water Pump

- Multi-Layer or Media Filter

- Activated Carbon Filter

- Automatic Water Softener

- Antiscalant Chemical Dosing System

- Product Water Storage Tank

- Post-Chlorination Dosing System

- Product Water Pump (Re-pressurization)

- Product Water UV Sterilize

RO Plant Advantages

- Better tasting water and food

RO has the ability to remove 95 to 99% of total dissolved solids (TDS) in drinking water and improve the odor, appearance, and overall taste of water.

- Health benefits

Reverse Osmosis (RO) water filtration has proven to be most effective when it comes to removing impurities from water in an efficient and cost-effective manner.

- Simple maintenance

While some water filtration and purification systems are difficult to manage and time-consuming to maintain, RO systems are quite easy.

Industrial Applications of Water Purifying Plants

- Textile manufacturing

- Pharmaceuticals

- Agriculture

- Poultry & Cattle Farms

- Hostels & Hospitals

- Power & Energy

How RO Plant has replaced DEMINERALISATION PLANTS, DM PLANTS (RESIN BASED)

DM water can be produced by multiple stages of passage through ion exchange resins and zeolites till there is virtually nothing other than water left. This purified water may be used for boiler feed water in power stations but not for drinking but is a very expensive process for town water supplies.

RO water is produced by a single pass of filtered water through an RO membrane. Due to leaks and slight imperfections, the membranes can contain up to about 1500 parts per million (0.15%) of assorted dissolved substances. That would be acceptable for drinking. RO plant requires power to run pressure pumps and fairly frequent replacement of membranes so is expensive but not as expensive as distillation or the full DM process. The reverse osmosis water purification plant price depends on the requirement of clients, and the where it will be used.

RO Recovery

RO recovery rate is influenced by the quality of the feed. The contaminants are generally inorganic salts and organics which

- raise the Osmotic Pressure

- foul the system’s membrane

The fewer TDS you have, the less applied pressure is required in order to push the water through the pores of the RO membranes. That is the reason BWRO can achieve up to 70-97% recovery (especially with new system configurations) and SWRO is limited to 35-45%.

Seawater Desalination with Reverse Osmosis Plant

All Reverse Osmosis plants are basically Desalination Plants but desalination is being referred to sea water normally.As sea water has very high TDS requires very high pressure to force sea water through membranes which are different then brackish water membranes.

Multiple Effect Distillation(MED) for seawater

As sea water desalination plants requires very high pressure pumps in short energy consumption is very high in sea water reverse osmosis systems forced to research for alternative of reverse osmosis plants for seawater desalination found Multiple Effect Distillation very cost effective in terms of energy consumption but fixed capital investment is bit higher. In many cases Multiple Effect Distillation(MED) would be associated with Thermal Vapour Compression ( MED TVC), or Mechanical Vapour Compression (MED MVC). And, Waterman Engineers Australia reverse osmosis plant price is the most competitive in the industry.