Necessity for Zero Liquid Discharge (ZLD) Systems in Slaughterhouses, Rendering, and Abattoirs

21.1 Introduction to ZLD

Zero Liquid Discharge (ZLD) is an advanced wastewater treatment approach designed to eliminate all liquid waste from a facility by recovering and recycling almost all wastewater generated. ZLD systems treat wastewater to such high standards that the treated water can be reused internally or safely discharged, with minimal or no liquid effluent leaving the plant.

21.2 Why ZLD is Crucial for Slaughterhouses, Rendering, and Abattoirs

21.2.1 High-Strength Wastewater Characteristics

- Wastewater from these facilities contains extremely high concentrations of organic matter, suspended solids, fats, oils, blood, proteins, nitrogen, phosphorus, and pathogens.

- Conventional wastewater treatment often cannot reduce pollutants below stringent discharge limits, especially in areas with limited water bodies or stringent environmental regulations.

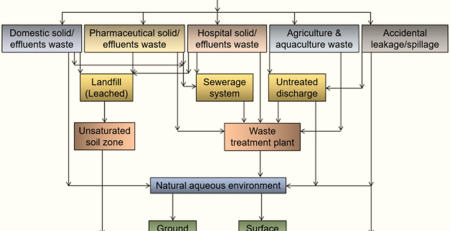

21.2.2 Environmental Protection and Regulatory Compliance

- Many jurisdictions are increasingly enforcing stricter limits on effluent quality to protect sensitive aquatic ecosystems.

- In arid or water-stressed regions, discharge restrictions are stricter, necessitating advanced treatment or complete elimination of liquid discharge.

- ZLD ensures compliance by fully capturing all wastewater and preventing surface or groundwater contamination.

21.2.3 Water Conservation and Reuse

- ZLD systems allow recovery of clean water suitable for reuse in cleaning, cooling, or process water, significantly reducing freshwater consumption.

- Water reuse is a critical sustainability goal for slaughterhouses and rendering plants, which are often large water users.

21.2.4 Odor and Nuisance Control

- By eliminating effluent discharge, ZLD reduces the risk of odor generation and nuisance complaints often associated with effluent holding ponds or discharges.

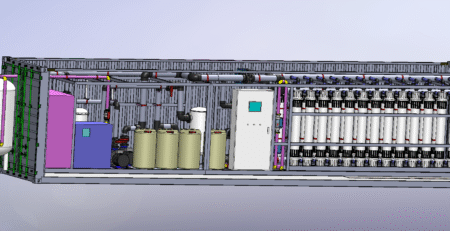

21.3 Components and Technologies in ZLD Systems for These Facilities

21.3.1 Pre-Treatment

- Screening, grit removal, and primary clarification to remove solids and fats.

- DAF units for removal of oils and grease.

21.3.2 Advanced Treatment and Concentration

- Biological treatment to reduce BOD and COD.

- Membrane filtration (ultrafiltration, nanofiltration) to separate solids and macromolecules.

- Reverse osmosis (RO) to concentrate dissolved solids.

21.3.3 Brine Concentration and Crystallization

- Evaporators or mechanical vapor recompression (MVR) systems to further concentrate RO brine.

- Crystallizers to precipitate salts and solids from the concentrate.

21.3.4 Solid Waste Handling

- Sludge dewatering and disposal of crystallized solids.

- Potential recovery of salts or minerals depending on composition.

21.4 Challenges and Considerations

21.4.1 High Energy Demand

- Evaporation and crystallization steps are energy-intensive, impacting operational costs.

- Integration of renewable energy or waste heat recovery can mitigate energy costs.

21.4.2 Complexity and Maintenance

- ZLD systems require skilled operation and regular maintenance to prevent fouling and scaling.

- Careful monitoring is essential to maintain system efficiency and longevity.

21.4.3 Capital Investment

- High initial costs due to advanced technologies and infrastructure.

- Requires cost-benefit analysis aligned with regulatory demands and water scarcity issues.

21.5 Benefits of ZLD Implementation

- Complete elimination of liquid effluent discharge, ensuring regulatory compliance.

- Significant reduction in freshwater intake through water recycling.

- Enhanced environmental stewardship and corporate social responsibility.

- Potential for resource recovery, including salts, nutrients, and water reuse.

- Minimization of pollution risk to surface and groundwater bodies.

21.6 Case Examples

- Several modern slaughterhouses and rendering plants in water-scarce regions have successfully implemented ZLD systems.

- Integration with anaerobic digestion and biogas recovery enhances overall sustainability.

- Plants report improved public perception and operational cost savings over time.

21.7 Conclusion

For slaughterhouses, rendering, and abattoirs, especially in regions with stringent discharge regulations or water scarcity, Zero Liquid Discharge systems represent an effective and sustainable solution for wastewater management. While capital and operational costs are significant, the environmental benefits, regulatory compliance, and water conservation advantages make ZLD a forward-looking investment toward sustainable industrial operations.

Technical Guideline and Design Framework for ZLD Systems in Slaughterhouses, Rendering, and Abattoirs

- Preliminary Assessment and Feasibility Study

1.1 Wastewater Characterization

- Comprehensive sampling and laboratory analysis for BOD, COD, TSS, FOG, nitrogen species (ammonia, nitrate), phosphorus, pathogens, heavy metals, and salinity.

- Understand seasonal variations and production-related fluctuations.

1.2 Water Balance and Flow Analysis

- Quantify daily and peak wastewater volumes.

- Evaluate opportunities for water reuse within the facility.

1.3 Regulatory Requirements

- Review local discharge standards, reuse guidelines, and permitting requirements.

- Identify specific effluent limits or zero-discharge mandates.

1.4 Energy and Economic Feasibility

- Preliminary estimate of energy consumption and operating costs.

- Cost-benefit analysis including savings from water reuse and avoided penalties.

- Detailed Engineering and Equipment Selection

3.1 Materials and Corrosion Resistance

- Use corrosion-resistant materials (stainless steel, FRP) for contact with high-strength and acidic/alkaline streams.

3.2 Automation and Controls

- Integration of SCADA systems for real-time monitoring and control.

- Alarms and safety interlocks for critical parameters (pressure, flow, temperature).

3.3 Energy Efficiency

- Heat recovery from process streams.

- Use of variable frequency drives (VFDs) for pumps and blowers.

- Consider renewable energy integration (solar thermal for evaporation).

- Construction and Commissioning

4.1 Site Preparation

- Ensure proper drainage, foundation, and access for maintenance.

4.2 Installation

- Follow manufacturer specifications for membrane modules, evaporators, and other key equipment.

- Install instrumentation for flow, pressure, conductivity, temperature, and water quality parameters.

4.3 Testing and Start-Up

- Initial flushing and cleaning of membranes.

- Stepwise ramp-up of biological and physical processes.

- Performance validation against design targets.

- Operation and Maintenance

5.1 Routine Monitoring

- Daily sampling of influent and treated water quality.

- Continuous monitoring of membrane flux, pressure drop, and cleaning frequency.

5.2 Preventive Maintenance

- Scheduled cleaning-in-place (CIP) for membranes.

- Maintenance of evaporators and crystallizers to avoid scaling.

- Inspection and replacement of wear parts.

5.3 Troubleshooting

- Protocols for membrane fouling, biological upsets, and energy inefficiencies.

- Environmental and Safety Management

6.1 Waste Disposal

- Environmentally sound disposal or reuse of crystallized salts.

- Safe handling and disposal of sludge to prevent contamination.

6.2 Odor and Gas Management

- Enclosed processes with gas scrubbing or biofilters.

- Monitoring of hydrogen sulfide and ammonia.

6.3 Worker Safety

- Training on confined space, chemical handling, and electrical hazards.

- Continuous Improvement and Innovation

- Incorporate feedback loops from monitoring data.

- Evaluate emerging technologies like forward osmosis, electrocoagulation, or advanced oxidation for future upgrades.

- Engage with research institutions for pilot testing and innovation.

Summary

Implementing a ZLD system in slaughterhouses, rendering, and abattoirs requires a carefully planned, multi-stage treatment train integrating biological, membrane, and thermal processes. Successful systems balance regulatory compliance, sustainability, and economic viability while protecting public health and the environment.

How ZLD Systems Save Water and Address Water Scarcity in Slaughterhouses, Rendering, and Abattoirs

- Maximizing Water Reuse through Complete Wastewater Recycling

ZLD systems are designed to treat and recycle almost 100% of wastewater generated by slaughterhouses, rendering, and abattoirs. Instead of discharging treated water as effluent, ZLD recovers clean water that can be reused in various plant operations such as:

- Cleaning and sanitation of equipment and floors

- Cooling systems

- Process water needs such as rendering or meat processing

- Irrigation of onsite green areas

This internal reuse dramatically reduces the need for fresh water intake, thereby conserving valuable water resources.

- Reducing Freshwater Demand in Water-Stressed Regions

Slaughterhouses and rendering plants are typically high water consumers due to cleaning, animal washing, and processing requirements. In water-scarce regions, reliance on municipal or groundwater sources strains local supplies and may lead to restrictions or operational disruptions.

By implementing ZLD, facilities become largely self-sufficient in water, requiring significantly less freshwater. This eases the burden on local water utilities and aquifers, contributing to regional water security.

- Preventing Pollution of Surface and Groundwater

ZLD eliminates liquid discharge by recovering water and isolating contaminants as solids. This prevents pollution of surface water bodies or groundwater sources, which otherwise might become unusable or hazardous.

Protecting these natural water sources helps maintain their availability for communities, agriculture, and ecosystems, indirectly supporting overall water sustainability.

- Enabling Circular Water Economy and Sustainability

ZLD promotes a circular water economy within the facility, where water cycles continuously through treatment and reuse loops instead of being wasted. This reduces the environmental footprint of the operation and aligns with sustainability goals.

Reduced water withdrawals also lower energy usage for water pumping and treatment elsewhere in the supply chain, amplifying the water-energy nexus benefits.

- Supporting Compliance with Increasingly Stringent Regulations

Many regions facing water scarcity are also imposing tight wastewater discharge restrictions to protect their limited water resources. ZLD enables slaughterhouses and rendering plants to comply without sacrificing operations.

By avoiding discharge, plants avoid regulatory fines and potential shutdowns, ensuring continuous operation and food supply chain stability.

- Potential for Integration with Rainwater Harvesting and Renewable Energy

ZLD systems can be integrated with rainwater harvesting systems to supplement process water supplies, further reducing dependence on external sources.

Energy-intensive components of ZLD (e.g., evaporation) can utilize renewable energy sources, making the overall water savings coupled with low-carbon footprint, creating a sustainable water-energy nexus.

Summary

Implementing ZLD in slaughterhouses, rendering, and abattoirs:

- Saves significant volumes of freshwater through high-efficiency water recycling

- Reduces environmental pollution, protecting natural water bodies

- Ensures operational resilience amid increasing water scarcity and regulations

- Supports sustainable industrial water management and circular economy principles

Thus, ZLD systems play a crucial role in addressing water scarcity challenges while enabling environmentally responsible wastewater management in these water-intensive industries.

Case Studies and Typical Water Savings with ZLD Implementation

Case Study 1: Large Slaughterhouse in a Water-Scarce Region

- Location: Arid region with limited freshwater supply

- Facility Size: 1,000 heads per day slaughter capacity

- Previous Water Use: 50,000 m³/month, mostly freshwater

- Wastewater Volume: Approximately 40,000 m³/month

Water Savings:

- Freshwater intake reduced from 50,000 m³ to 2,500 m³ per month (95% reduction).

- Sludge and solid salt by-products handled separately.

Benefits:

- Ensured continuous operation despite regional water restrictions.

- Reduced environmental discharge to near zero.

- Achieved regulatory compliance with stringent water reuse standards.

Case Study 2: Medium-Sized Rendering Plant with ZLD Upgrade

- Location: Semi-arid region with increasing water costs

- Facility Size: Processes 200 tons of raw material daily

- Previous Water Use: 15,000 m³/month

- Wastewater Volume: 12,000 m³/month

ZLD System Water Savings:

- Approximately 90% of water recycled onsite.

- Freshwater consumption dropped to ~1,500 m³/month.

Economic Impact:

- Operational cost savings in water purchase and effluent fees exceeded the increased energy cost after 2 years.

- Enhanced corporate environmental responsibility profile.

Typical Water Savings and Efficiency Metrics

| Facility Type | Typical Freshwater Use Reduction (%) | Typical Water Reuse (%) | Notes |

| Slaughterhouse (Large) | 90-98% | 90-95% | Dependent on process integration |

| Rendering Plant (Medium) | 85-92% | 85-90% | Energy recovery critical |

| Abattoir (Small) | 80-90% | 80-85% | Cost-sensitive systems |

Key Takeaways

- ZLD systems can reduce freshwater use by up to 98%, making near-total water recycling achievable.

- Water reuse percentages consistently exceed 85% across different facility sizes.

- Integration with energy recovery systems enhances economic viability.

- Facilities gain operational resilience and meet increasingly strict environmental regulations.