Mining Industry (Mineral Ore Processing) Wastewater Treatment Technologies

Overview:

The mining industry is one of the most important earning sources for many different countries. This industry might be categorized under chemical industries or geophysical industries based on characteristics of the mining industries. Even though mining industry is less diverse it is important to understand waste management initiatives or exploring initiatives so that mining generated waste can be minimized at source and accidents can be tackled to protect the environment and environmental components. Mining industry consists of a cluster of process that are involved in the extraction, management and processing of naturally occurring solid minerals from the earth surface. Coal, diamond, metallic ores, oil, and so on are economically valuable products that can be obtained from mining. Mineral processing, surface mining, market of mining equipment, and other processes are also a part of the mining industry.

Water is used in large quantities for mineral processing. Mineral processing requires about 500 litres for every ton of ground. As mined ores continue to trend towards lower and lower grades, the need for more water is likely to increase. The mining industry depletes water supplies with high usage and pollutions them with discharges from waste rock impoundments. Water is preferred in mineral processing because it is a low cost and low energy way of transporting materials between processes. It is an essential ingredient for some chemical processes and is a very efficient medium for supplying chemicals and mixing materials. It is the most convenient medium for separation of minerals from rocks. In mining application, treatment wastewater is a crucial step. Water is used to recover metals from ore. Mainly the usage of water in mining industry is for mineral processing, dust suppression, slurry transport and employees’ needs. Mostly water used in mining operations come from groundwater streams, lakes, rivers or from commercial water suppliers. During this process mineral contaminants and other solids accumulate in the water, contamination it. This contaminated mining water can neither be reused or returned to the environment without treatment. Some mining companies pay outside companies to collect and transport wastewater which can be inefficient and costly. Wastewater can also be stores in retention ponds, but they lose their effectiveness overtime. One of the most effective ways of treating wastewater is on-site with various chemicals and filtration methods. Onsite treatment has several benefits like,

- Cost effective.

- Long-term sustainability and full control of treatment process.

- Water can be reused once treated.

- Maximum water can be recovered with near close-lopped solution.

Water is used in large quantities for ore processing those effects freshwater reserves moreover water also gets polluted from discharged mine effluent and tailings and waste rock impoundments seepage.

Mine water types and uses:

Large quantities of water are used in mining industries for the purpose of mineral processing and refining, dust suppression, slurry transport, tailings disposal, and potable and hygiene needs. Water is qualified in three categories-based on quality:

- Raw water: This water comes from precipitation, rivers, and lakes. It is used for many things, including employee needs, process make-up water, shaft and underground mine water demand, mobile fleet washing, and fire water.

- Compliant flow (non-contact water): This is clean surface runoff water. This water is usually separated from the contaminated mine areas to reduce treatment requirements and facility sizes.

- Non-compliant flow (contact water): Water having contact with mining, mineral processing, and tailings disposal is called contact water and cannot be directly released into the environment without treatment. In order to minimize freshwater consumption, this water is usually collected and used on site for various purposes. Any excess contact water that is not reused will need to be treated.

Processes in mining industry (mineral ore processing):

After the extraction mineral ore is processed in the mining industry by using the following methods:

- Size reduction (Crushing, Grinding)

- Size control (Screening, Classification)

- Enrichment (Washing, Gravity separation, Flotation, Magnetic separation, Leaching)

- Upgrading (Sedimentation, Mechanical dewatering, Thermal drying, Thermal processing)

- Materials handling (Unloading, Storing, Feeding, Conveying)

- Slurry handling (Slurry transportation, Agitation and mixing)

- Wear in operation

- Operation and environment

- Process systems

Metallurgical process can result in the release of large amounts of acidic and alkaline waters that have high concentrations of sulphates, cyanides, trace metals etc. During flotation metal elements are liberated into the process water due to the surface dissolution of minerals.

Characteristics of wastewater:

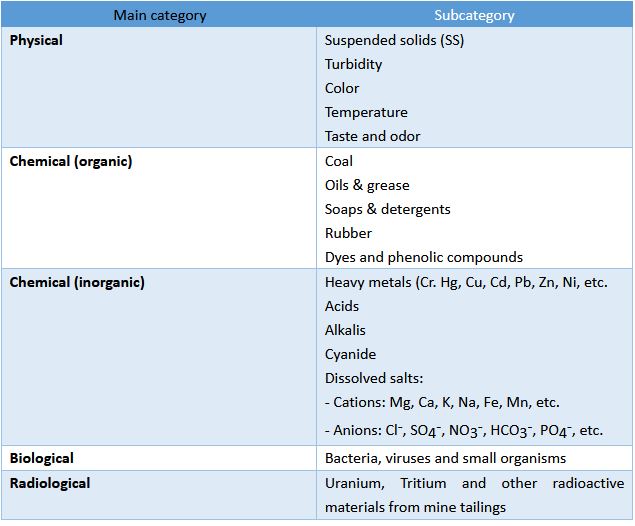

In mining industry, the contamination of water can be placed in five main categories i.e., physical, chemical (organic), chemical (inorganic), biological and radioactive. Biological pollutants mostly come from domestic or sanitary sources. Radioactive pollutants come from uranium deposits and open-cut mines. In the mining industry the physical and chemical type of pollutants are most critical.

Contaminants in wastewater:

Temperature:

Water temperature is a good indicator of biological activity. When the temperature of water is within the range of 5 oC to 30 oC, every 10 oC increase in the temperature of water results in the doubling of biological activity. However, the mining operations that add excess heat to the mine effluent are few, therefore thermal pollution is not considered a major problem associated with mining.

pH:

The solubility of metals in water depends on its ph. Precipitation of metal oxides is induced at high pH, whereas low pH values result in soluble species. The rang of pH scale if from 0-14, where a pH value of 7 is considered neutral. In case of coal that has high Sulphur content, the Sulphur can react with water and oxygen in the presence of bacteria resulting in the production of Sulphur acid. The acid lowers the pH of water. Water with pH bellow l6.5 can be corrosive to plumbing fixtures and reticulation.

Suspended solids:

When solid matter concentrates in water in suspended form, it gives rise to the most common and visible water pollution problem. In mining wastewater suspended solids consist of silt and fine ore material, that can remain suspended in water for prolonged periods of time.

Total Dissolved Solids (TDS) and Electrical Conductivity (EC):

TDS means the total dissolved solids content of water, whereas electrical conductivity refers to the ability of aqueous solution to carry electrical current. Coal mining discharges have a high level of mineralization and in most cases, a relationship can be established between total dissolved solids and electrical conductivity. Due to which total suspended solids can be easily determined because electrical conductivity can be measured readily using instruments. The electrical conductivity of mine water ranges from 1000-10,000 µS/cm.

Turbidity:

Indirect measurement f suspended solids in water is called turbidity. The suspended matter can scatter the light, which gives water a cloudy appearance. When turbidity increases, light penetration deceases and heat absorption increases which renders the water unfit for use. Moreover, particles causing turbidity acts as a medium of transport and absorption for bacteria.

Alkalinity:

Alkalinity is defined as the measure of waters ability to neutralize acids. Water that has high alkalinity cannot be used because it is caustic. However, if mine water has access alkalinity the reduction in pH due to biochemical reaction of Sulphur compounds with water can be avoided.

Acidity:

Dissolution of carbon dioxide and sulfuric acid can cause acidity in mine waters, due to which pH will reduce resulting I the dissociated of unwanted metals in the water.

Chloride:

Chloride is normally present in water in small quantities. However, water with high concentration of chloride and cause corrosion in pipe systems. Also, water with high chloride level cannot be used for irrigation or for domestic purposes.

Sulphates:

Some quantity of sulphate is naturally present in water, however biological oxidation of pyrites can result in dissolved sulphate which can increase the concentration of sulphate leading to laxative effect on the consumer and unpleasant taste.

Nutrients (Nitrogen and phosphorous):

In mine wastewater the concentration of nitrogen is small and is not considered a problem. Phosphorous occurs I the water as phosphate and it is essential for plants growth. However excess qualities can lead to eutrophication. Phosphate discharge is a problem only in phosphate mines, however, in other mines phosphate is present in trace amount and isn’t a problem.

Non-toxic metals:

In mine waters, metals such as Na, K, Ca, Mn, Fe and Mg can be found in varying concentrations. These metals are considered non-toxic, however, Ca and Mg ions can cause water hardness, whereas Fe and Mn ions can cause discoloration of water. They can also get deposited in pipe handling systems.

Toxic metals:

In coal industry metals like aluminium, zinc and barium can be found in water, however, the quantities are small. Depending on the type of processing used, in metalliferous mining industry metal effluents may contain arsenic, cadmium, chromium, copper, gold, lead, mercury, vanadium and in the case of uranium mining, other radioactive substances may be present.

It is important to categorize, assess and control the discharge of these in both discontinued and active mines in order to protect the environment. If not controlled, heavy metals discharged from the mines can contaminate waterbodies and damage aquatic life.

Wastewater treatment in mining industry (Mineral Ore Processing):

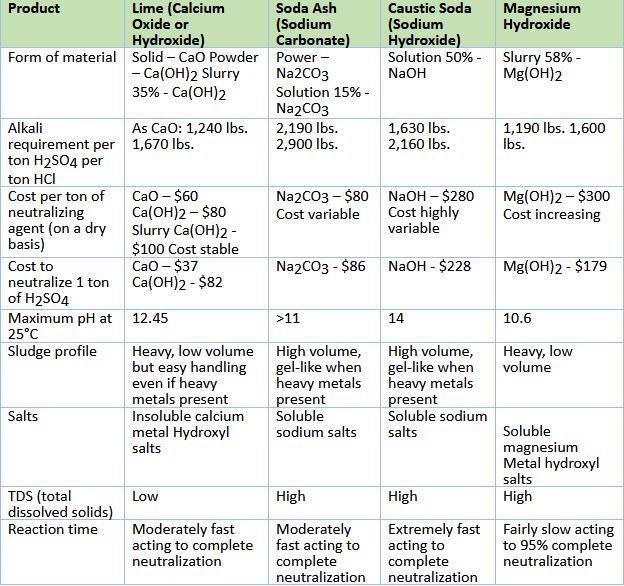

pH adjuster chemicals: Restoring the pH level to the correct range is one of the first things to consider while treating wastewater from mining activities. adjusting the pH can help maintain the water quality and prevent the metals from being suspended and dissolving in water. A chemical reaction occurs when the pH of the water is being raised, resulting in insoluble metal particles that can be easily dealt with. Chemical pH adjusters will aid in reducing the acidity of the wastewater, with the goal of achieving a pH of around 8 before moving on to the additional treatment options.

Using flocculants and coagulants: Coagulants and Flocculants are special chemicals that clump together the small metal particles and other solid pollutants suspended in the used water which makes it easier to filter them out. There is a wide variety of wastewater coagulants available, each developed for a specific application, so it’s critical to choose the right one for your needs.

Mining wastewater and sludge dewatering techniques: It is critical to treat the sludge produced during the mining operation. One of the most crucial steps in this process is to eliminate any extra water from the sludge that results in a solid waste that can be readily controlled, disposed of, and transported. this procedure is called Sludge dewatering

Sludge dewatering processes vary, and the best one relies your budget, available space, kind of mining, environmental circumstances and local geology. Following processes are mostly used in mining industries.

Hydro cyclones: The use of hydro cyclones is one of the most common techniques for dealing with sludge in the mining sector. This technique is efficient in removing solids from water and is used in many settings due to its versatility and efficacy. In this technique centrifugal force is used in order to remove solids from wastewater. The main advantage of this technique is that it can process large amount of wastewater without requiring a lot of floorspace and has no moving parts. However, it can’t be used in isolation and another wastewater treatment process has to be used with it.

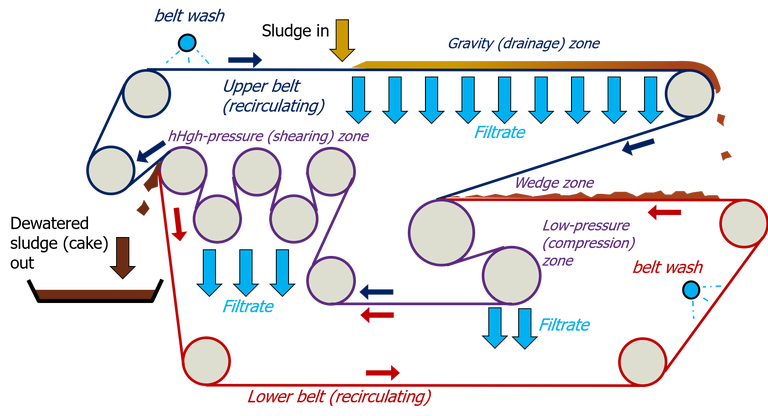

Belt Press Filter: In mining operations, belt press is a very popular choice as it is quick to set up and doesn’t require high initial investment. Therefore, they are commonly used for dewatering mining sludge processes as they are cost effective. It consists of two moving belts that are running between rollers. Wastewater passes over the belts and through the rollers and solids are collected in the form of clumps known as cake. These clumps can be easily removed from the belt press.

Although, initially belt press is easy and cheap to set up however it becomes expensive to run because:

- It requires flocculant.

- Replacing belts is expensive and they need to be replaced frequently.

- The solid cake produces in the end need to go through further processing before disposal.

Filter presses: This is the most efficient and top-rated method for the removal of solids from wastewater. Waste slurry is pumped through various chambers of filter press by pumps. The chambers consist of plates that removes solids when the slurry passes through. In the end the treated water from the press is released back into the system. Filter presses are efficient and cost effective.

In mining industry two types of filter presses are used low pressure filter press and high-pressure filter press. However, due to inefficiency and complexity, low pressure filter presses are less commonly used in the mining industry.

Neutralization: Pollution control measures that are required to preserve receiving stream biota include neutralization of excessive acidity in wastewater. For large consumptive uses, first consideration is usually given to a low-cost material such as lime or limestone, which can be used for acid neutralization. Many factors may be involved in neutralization. The use of limestone for neutralizing acidic wastewater is attractive because it is available in many areas at the lowest cost per unit of basicity. Limestone neutralization has a reputation of being unreliable due to the high incidence of failures in the past. Fouling is the main problem associated with stationary bed of limestone.

Precipitants to treat the Mining water

Gravity sedimentation: This process is used in ore dressing operations for clarification of water to either reuse it or discharge it. Water is separated from finely ground ore and tailings by using settling tanks or thickeners and tailing ponds. Apart from water recovery and pollution abatement, this process also helps in the recovery of chemical reagents used in used in flotation circuits.

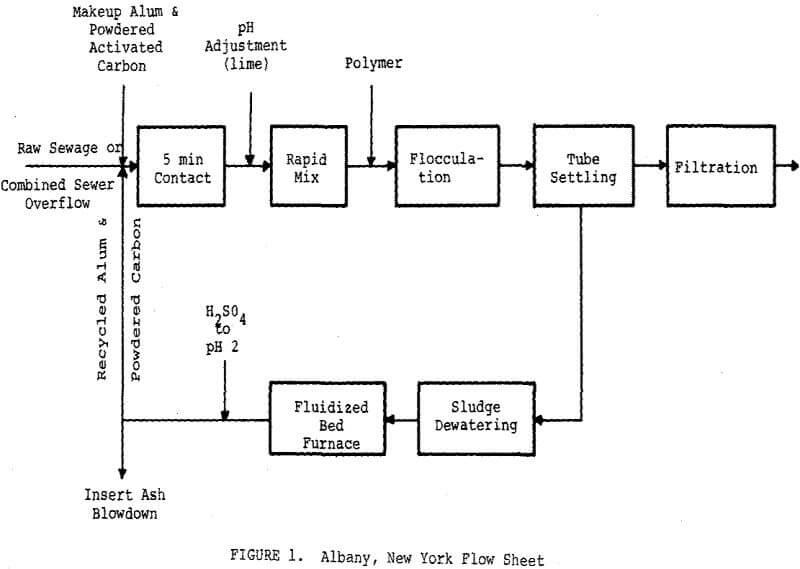

Activated carbon: Activated carbon is used in powdered as well as granular form. granular activated carbon has been economically and successfully used for the treatment of secondary effluents at South Lake Tahoe. This plant’s spent carbon is removed from the carbon beds for thermal regeneration and then returned to the beds for reuse. Wastewater treatment techniques based on powdered activated carbon are currently being developed, and they offer a lot of promise in terms of lowering treatment facility capital costs. Powdered carbon techniques remove both suspended debris and dissolved organics at the same time.

Physical-chemical methods: There are many physical-chemical methods that can be used for wastewater removal. Wastewater treatment involves the removal of one or more substances rather than bulk separation of the dissolved matter from the wastewater. Chemical treatment can be used to remove undesirable substances from wastewater. Chemical precipitation methods are one of the most economical ways to clean up wastewater. Inexpensive chemicals such as lime can be used to effect precipitation reactions. The low cost of the sedimentation process makes the equipment required for precipitation processes relatively inexpensive. Addition chlorine, hypochlorite salts, ozone, chlorine dioxide, permanganate salts and other oxidants can be used to oxidize wastewater.

The most used chemicals in mining wastewater treatment are pH adjusters and specialist coagulants, but there are a variety of other specialty chemicals that can be utilized to a great advantage. Corrosion inhibitors and biocides, for example, are used to restrict the growth of algae and bacteria. In locations with hard water, water softeners may be beneficial.

Treatment of wastewater using membrane technologies:

This Wastewater Recovery treatment is mainly used to treat water polluted with polycyclic aromatic hydrocarbons. This method removes impurities from water by using barrier that allows certain substances to pass and block the others. Depending upon the contaminants, several different types of membranes can be used. Apart from other mechanisms such as hydrophobic effects and adsorption on the membrane surface, these technologies use size exclusion as a means of removing pollutants during the treatment of polluted waterways. Microfiltration, ultrafiltration, nanofiltration, and reverse osmosis are all membrane technologies. The latter is a water purification process that relies on high-pressure membrane filtration.

Membrane filtration- Microfiltration and ultrafiltration: This process uses microfiltration and ultrafiltration membranes to treat wastewater and is similar to sand or media filters that can remove suspended solids but not dissolved solids. This process can work under pressure and vacuum and is commonly used to treat wastewater to remove bacteria and viruses.

Reverse Osmosis—Nanofiltration/Membrane Softening: Osmosis is defined as the tendency of two solutions of varying salinities to neutralize. Reverse osmosis overcomes the natural tendency through pressure and forces the pure water through a semi permeable membrane while the pollutants are concentrated on the feed side of the membrane.

Nanofiltration operates the same way reverse osmosis does. The only difference is that the membrane is a bit loose and allows salts to pass through while blocking larger dissolved molecules.

To remove bacteria and other contaminants found in the water as molecules and ions, reverse osmosis uses nonporous filter membranes (0.2-1.0 nm) and works by using steric effect or dimensional exclusion electric charges, exclusion, and solute-solvent-membrane physicochemical interactions. It is more effective than standard procedures for removing bioorganic pollutants from wastewater from homes and biomedical centres, such as hormones and bioactive components of pharmaceuticals.

Reverse osmosis, which has been utilized in the manufacture of drinking water for more than 30 years, is now being employed more frequently in the treatment of wastewater. Membrane filtration has been a more viable option in the production of recyclable water from industrial effluent since 1990, thanks to the development of environmental regulations in both developed and developing countries.

Benefits of treating wastewater:

- Provides Clean and Reusable Water: Throwing away wastewater is harmful to nature. If there is any water that cannot be used for consumption, it should be treated so that it won’t affect the atmosphere. Wastewater can be treated through an industrial water plant and can be reused. It can be further refined for human consumption.

- Protect Environment: Wastewater contains a lot of waste materials. The water from the industrial sector contains harmful chemicals that can be fatal if left in the open. The industrial water treatment plant can remove the harmful ingredients from the water. Therefore, the water can be used for personal or industrial purposes and this will help in the reduction of environmental pollution as well.

- Keeps Disease Away: Wastewater contains bacteria, viruses and other chemicals that can make the consumer sick and can also be fatal. Treatment of wastewater can help reduce the risk of diseases from consumption of water.

- Strengthens Economy: A lot of money goes into preventing pollution. Millions of dollars are spent for cleaning contaminated water bodies. So, treatment of water on site can help save money.

- Produces Energy: Water can be used for the production of electricity. The industrial water treatment plant can use its own power during the treatment process. Electricity can be generated while the water treatment process is on. It can sell the rest of the electricity to the national grid.

- Avoid Industrial Equipment Damage: Waste can damage industrial equipment and pipe systems.

- Minimize waste: Water treatment can help in the minimization of waste. Moreover, it can also prevent the wastage of water.

How Mining Industry Can Improve Water Efficiency:

There are following way to improve the water efficiency in Mining Industry (Mineral Ore Processing):

-

- Evaluate Opportunities for Energy and Chemical Optimization: One way to improve water efficiency in the mining industry is to evaluate opportunities for energy and chemical efficiency. It means that industries need to find out if there is a possibility to lower the energy usage by water resources at mines such as aerators, blowers, and pumps.

- Ensure Compliance by Optimizing Chemical Dosage in the Water/Wastewater Treatment Processes: The next step is to make sure that the water/wastewater treatment process is complying by maximizing chemical dosage. With the use of artificial intelligence, industries can maximize their chemical dosage setpoints without straying from the compliance limits.

- Leverage Artificial Intelligence to Reduce Energy in Water/Wastewater Treatment Processes to Lower Water Related Costs: Artificial intelligence can reduce energy in water treatment processes and can help save on water related costs. By installing an artificial intelligence system at the mining site, it becomes easier to monitor the water assets remotely for energy consumption. This will also help to save energy and money.

- Ensure Wastewater Treatment Processes Are Reusing as Much Water as Possible: It is important to reuse as much water as possible. Water efficiency cannot be achieved if water usage if not optimized for wastewater treatment process.

- Leverage Historical Data to Enable AI to Help Optimize Water and Wastewater Treatment Processes: Predicting is done based on what has happened in the past. In order to improve water and wastewater treatment processes at mining sites, industries need to provide past data related to that so AI can learn from it and make predictions.

- Ensure Wastewater Treatment Process Is Leveraging AI to Optimize Water for Reuse: Artificial intelligence allows operators to recirculate process water to minimize water intake, tailing storage, and effluent discharge volumes. Industries can save up to 30% on operational expenditures by enabling intelligent water and wastewater operations.

- Increase Water Reuse by Optimizing Membrane Downtime and Recovery: The seventh and final way the mining industry can improve is by increasing the reuse of water through optimization of membrane downtime and recovery. Artificial intelligence can help do this by enabling membrane recovery optimization, membrane cleaning scheduling, and filtration optimization.