Mining Industries Water Treatment Plant on Hire, on Rental

FOR AUSTRALIAN CLIENTS ONLY

- Executive Summary

- Overview of the hire model for mining water treatment

- Key benefits and applications

- High-level economic and environmental case

- Introduction

- Importance of water management in mining

- Environmental regulations and compliance

- Common water-related challenges in mining operations

- Role of mobile/modular water treatment plants

- Water is a critical resource for the mining industry, underpinning every stage of mineral extraction and processing. From ore washing to dust suppression, slurry transport to tailings management, mining operations consume significant volumes of water while also producing complex wastewater streams laden with suspended solids, dissolved minerals, and other contaminants.

- In recent decades, heightened regulatory scrutiny and the mining industry’s commitment to sustainable practices have driven a fundamental shift in how water is managed at mine sites. Increasingly, mining companies must demonstrate responsible water stewardship to secure licenses to operate, maintain stakeholder trust, and safeguard surrounding ecosystems.

- One of the most pressing challenges miners face is dealing with variable water flows and unpredictable contamination profiles. Seasonal weather, changing ore bodies, and fluctuating production levels can all contribute to significant variability in both the quantity and quality of water requiring treatment.

- Traditionally, mining companies have invested in large, fixed water treatment plants. While effective in some contexts, these permanent installations come with high capital costs, long lead times, and limited flexibility to adapt to changing operational needs or short-term projects. Moreover, once a mine reaches the end of its life, the treatment plant often becomes redundant.

- In response, the industry is increasingly turning to water treatment plants on hire — a flexible, scalable, and cost-effective solution. A hire model allows mining operations to rapidly deploy modular, containerized, or skid-mounted treatment systems that can be tailored to specific site conditions and moved or redeployed as needed. This approach shifts the cost burden from capital

expenditure (CAPEX) to operational expenditure (OPEX) and enables companies to meet strict discharge or reuse standards without the commitment of building permanent infrastructure.

- Whether it’s treating acidic pit water in a decommissioned open cut, removing heavy metals from tailings seepage, or ensuring compliance with discharge regulations during seasonal high-flow events, water treatment plants on hire have become a vital tool in modern mining water management.

- This document provides a comprehensive overview of how the hire model works, the technologies involved, key benefits and considerations, and best practices for successful implementation in the mining sector. It is intended as a practical guide for mine operators, consultants, regulators, and equipment providers navigating the challenges and opportunities of flexible water treatment solutions.

- Mining Process Water Sources and Treatment Needs

- Types of wastewater in mining: process water, mine dewatering, tailings water, pit water, etc.

- Contaminants of concern (TSS, heavy metals, salinity, pH, organics)

- Typical flow rates and seasonal variations

Water is both a critical input and a significant output in mining operations. Understanding the various sources and characteristics of mine water is essential to designing effective treatment systems — whether permanent or hired on a modular, mobile basis.

3.1 Major Sources of Mining Wastewater

Mining activities generate multiple streams of wastewater, each with distinct flow rates, contaminant profiles, and treatment challenges. The main categories include:

a) Process Water

Used extensively in mineral processing for grinding, ore washing, flotation, and separation, process water can contain suspended solids, residual chemicals (flocculants, reagents, surfactants), dissolved metals, and elevated salinity levels.

b) Mine Dewatering Water

Groundwater inflow must often be pumped out to keep pits and underground workings dry. This dewatering water can contain dissolved metals (iron, manganese, arsenic), acidity (in sulfide ores), or total suspended solids (TSS) from geological strata.

c) Tailings Pond Water

Tailings facilities store residual slurry after ore processing. Decant or seepage from these ponds typically has high TSS, dissolved heavy metals, residual process chemicals, and elevated salinity. Managing tailings water is crucial to prevent seepage into surrounding aquifers.

d) Pit Water and Stormwater Runoff

Open pits collect rainwater mixed with dust, debris, and exposed minerals, which can produce acidic runoff and leach metals. Seasonal rainfall can dramatically increase pit water volumes, requiring rapid deployment of temporary treatment plants.

e) Acid Mine Drainage (AMD)

One of mining’s most persistent environmental legacies, AMD forms when sulfide minerals react with oxygen and water, generating sulfuric acid that dissolves metals. AMD often requires active or passive treatment to neutralize acidity and remove metals.

f) Camp and Domestic Wastewater

Mines with remote workforce camps generate domestic sewage that must be treated to meet local effluent standards. While less complex than process streams, this can be integrated with larger mobile treatment units.

3.2 Typical Contaminants and Water Quality Challenges

Mining wastewater is complex due to variable geology, mining methods, and climatic conditions. Common water quality parameters of concern include:

| Parameter | Typical Issue |

| Total Suspended Solids (TSS) | High sediment loads from ore washing, pit dewatering |

| pH | Low pH (acidic drainage) or high pH (lime dosing residues) |

| Heavy Metals | Arsenic, cadmium, lead, zinc, copper, iron, manganese |

| Salinity | High TDS in brines or from saline groundwater |

| Cyanide | Present in gold mining effluents |

| Sulfates | Common in sulfide ore operations |

| Organics | Flotation reagents, oils, hydrocarbons |

| Nutrients | From domestic wastewater (nitrogen, phosphorus) |

3.3 Seasonal and Operational Variability

Unlike municipal or industrial plants with stable inflows, mine water treatment must adapt to:

- Seasonal rainfall: Wet seasons can flood pits and tailings dams.

- Changing ore bodies: Different ores release different metals.

- Production fluctuations: Temporary closures, ramp-ups, or expansions affect flow rates.

- Temporary works: Short-term dewatering or site rehabilitation.

This unpredictability makes hire-based modular plants especially attractive. Operators can scale capacity up or down, add treatment stages, or relocate units as conditions change.

3.4 Key Treatment Objectives

Regardless of source, the overarching goals of a mining water treatment system are to:

- Protect the Environment: Meet or exceed discharge limits to surface or groundwater.

- Enable Water Reuse: Maximize recycling for dust suppression, ore processing, or site rehabilitation.

- Ensure Regulatory Compliance: Avoid fines, license breaches, or reputational damage.

- Safeguard Site Safety: Prevent uncontrolled discharge or flooding.

- Technologies Used in Mining Water Treatment

- Filtration, sedimentation, flotation

- Reverse osmosis, ultrafiltration, nanofiltration

- Ion exchange, chemical dosing, pH adjustment

- Evaporation, crystallization

- Zero Liquid Discharge (ZLD) systems

- A wide range of proven and emerging technologies can be deployed in modular hire plants for mining applications. The choice depends on contaminant type, discharge standards, site conditions, and mobility requirements.

· 4.1 Physical Treatment Methods

- a) Sedimentation and Clarification

Settling tanks, lamella clarifiers, or mobile clarifier units remove suspended solids and grit. Coagulation and flocculation chemicals are often dosed to enhance settling. - b) Filtration

Sand filters, multimedia filters, or disc filters polish clarified water by removing residual TSS. Mobile filtration skids are common in hire fleets. - c) Dissolved Air Flotation (DAF)

Effective for removing fine particles, oils, and grease. DAF systems inject microbubbles to float contaminants to the surface for skimming.

· 4.2 Chemical Treatment Methods

- a) pH Adjustment and Neutralization

Acid mine drainage requires lime or caustic dosing to raise pH and precipitate metals. Automated dosing skids with online pH control are standard. - b) Coagulation and Flocculation

Used to aggregate fine particles for sedimentation or flotation. Coagulant storage and dosing systems are integrated into modular plants. - c) Oxidation and Reduction

Chemical oxidation (e.g., with hydrogen peroxide, ozone) can break down cyanides or oxidize ferrous iron to ferric for precipitation.

· 4.3 Membrane-Based Processes

- a) Ultrafiltration (UF) and Microfiltration (MF)

These remove fine suspended solids and colloidal matter as a pretreatment to reverse osmosis or for producing high-quality reuse water. - b) Reverse Osmosis (RO)

Key for desalination of brackish water or high-TDS effluent. Mobile RO skids are widely used for pit dewatering or reuse. - c) Nanofiltration (NF)

Useful for selective ion removal, especially where partial desalination is required.

· 4.4 Ion Exchange and Adsorption

- Ion exchange resins can target specific dissolved metals like arsenic or ammonia. Adsorbent media (e.g., activated carbon, zeolite) help remove organics or trace contaminants.

· 4.5 Evaporation and Zero Liquid Discharge (ZLD)

- For sites aiming for minimal discharge, mechanical vapor recompression (MVR) evaporators, multi-effect evaporators (MEE), or thermal brine concentrators can reduce liquid waste volumes. These can be containerized for hire and deployed to remote sites.

· 4.6 Sludge Management

- Sludge from clarifiers, DAF, or chemical precipitation must be dewatered. Mobile belt presses, centrifuges, or filter presses handle this step. Dewatered cake is easier to transport or dispose of at licensed facilities.

· 4.7 Automation, Instrumentation, and Remote Monitoring

- Modern modular plants integrate smart PLCs, SCADA, IoT sensors, and cloud-based dashboards to enable remote performance monitoring and predictive maintenance. This is crucial for remote mining sites where local technical support is limited.

- The Concept of Plant on Hire (Rental Model)

- What is a water treatment plant on hire?

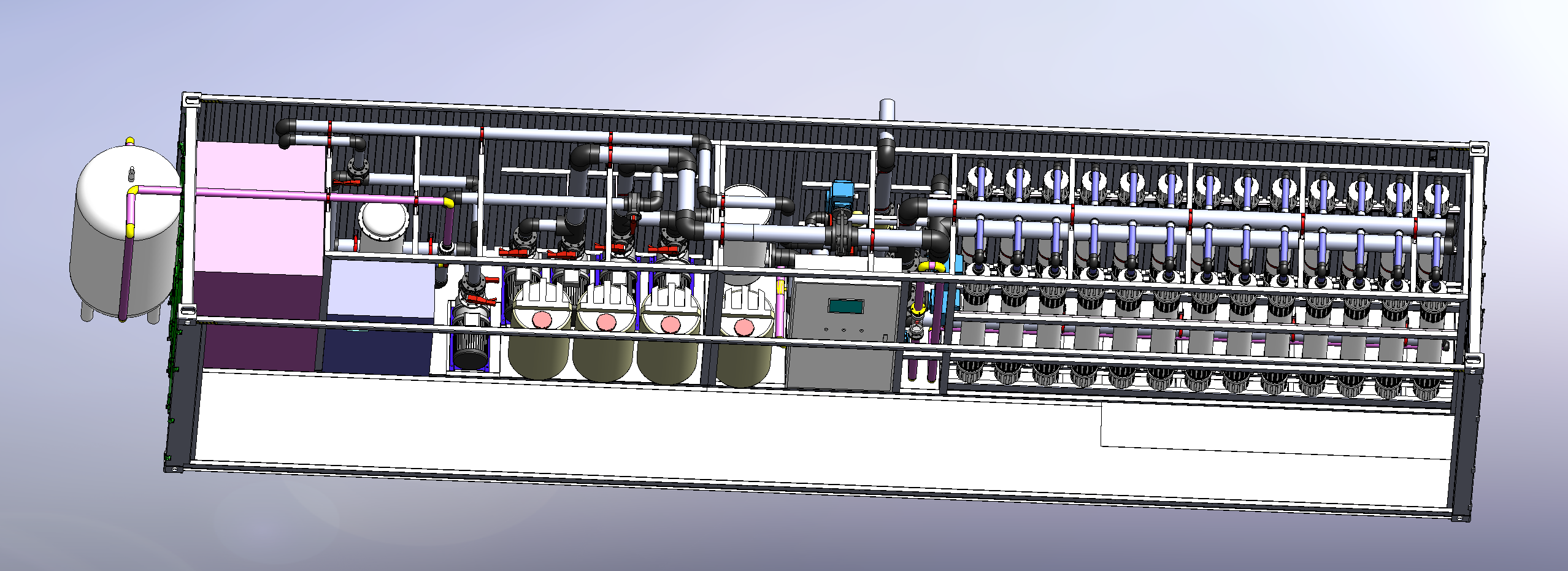

- Types: containerized, skid-mounted, trailer-mounted

- Duration: short-term, long-term, emergency response

- Service inclusions: design, installation, commissioning, O&M

The concept of a water treatment plant on hire — also referred to as rental, lease, or temporary deployment — has gained significant traction across the mining sector in recent years. It offers a practical solution to the sector’s unique challenges: variable water flows, remote locations, short project timelines, and evolving regulatory demands.

5.1 What is a Water Treatment Plant on Hire?

A plant on hire is a complete, pre-engineered, modular water treatment system that is owned and maintained by a specialist service provider but deployed to the client’s site for a defined period under a rental agreement.

Instead of committing to the capital outlay and construction timeline of a permanent installation, mining companies can lease fully functional treatment plants tailored to site-specific requirements. These systems are designed for rapid deployment and relocation.

5.2 Common Configurations

a) Containerized Units

Treatment modules housed in standard shipping containers (10ft, 20ft, 40ft). Ideal for remote sites — easily transported by truck or rail and rapidly commissioned.

b) Skid-Mounted Systems

Process equipment mounted on portable skids for easy lifting and placement on-site. Skids can be combined to form multi-stage treatment trains.

c) Trailer-Mounted Plants

Smaller mobile units mounted on trailers for extreme mobility. Suitable for rapid response to sudden dewatering or spill events.

d) Hybrid Setups

A combination of fixed-site infrastructure (e.g., large clarifier tanks) with modular plug-in treatment modules for polishing or additional capacity.

5.3 Service Scope

A reputable water treatment hire provider typically offers an integrated package including:

- Site Assessment: Process design and sizing based on raw water characteristics.

- Custom Engineering: Selection and configuration of modular units.

- Logistics: Delivery, installation, and commissioning on-site.

- Operation and Maintenance (O&M): Staff training, chemical supply, consumables, and remote monitoring.

- Demobilization: Dismantling and site restoration at the end of the contract.

5.4 Typical Hire Scenarios

Mining companies hire treatment plants for diverse needs, including:

- Rapid deployment for seasonal pit dewatering during high rainfall.

- Temporary treatment while waiting for a permanent facility to be built.

- Pilot testing new treatment technologies at pilot scale.

- Emergency response to accidental spills or unexpected contamination.

- Decommissioning and mine closure phases where legacy water must be treated.

- Advantages of Hiring vs. Building Permanent Plants

- Cost-effectiveness

- Flexibility and scalability

- Speed of deployment

- Risk mitigation and regulatory compliance

- CAPEX to OPEX shift

- For many mining operations, a hire model offers significant operational, financial, and environmental advantages compared to investing in fixed treatment infrastructure.

· 6.1 Flexibility and Scalability

- Mining projects are dynamic. Ore grades change, pits expand or close, and seasonal water balances fluctuate. A hire model lets operators adjust capacity quickly by adding or removing treatment modules.

· 6.2 Speed of Deployment

- Designing, permitting, and constructing a permanent plant can take 12–24 months. In contrast, modular plants can be delivered and commissioned in weeks — critical for responding to compliance deadlines, wet season floods, or unexpected inflows.

· 6.3 Lower Upfront Costs

- A permanent plant is a major capital expenditure (CAPEX). By hiring, the cost shifts to operational expenditure (OPEX), preserving capital for core mining activities.

· 6.4 Reduced Long-Term Risk

- If a mine’s lifespan is uncertain, investing in a fixed facility can leave stranded assets. A hire arrangement reduces long-term risk — when the plant is no longer needed, it is demobilized and redeployed elsewhere.

· 6.5 Access to Latest Technology

- Hire providers continuously invest in modern, efficient equipment to remain competitive. This means mining companies gain access to state-of-the-art treatment processes and automation without investing in upgrades themselves.

· 6.6 Compliance and Liability Protection

- Reputable hire providers offer performance guarantees, ensuring treated water meets discharge standards. This helps operators meet environmental obligations and avoid fines.

- Design and Specification Considerations

- Modular design for diverse sites

- Automation and remote monitoring (SCADA, IoT, AI)

- Footprint, mobility, logistics

- Safety and environmental standards

When planning a water treatment plant for hire, careful design is vital to ensure robust performance, mobility, and compliance with site constraints.

7.1 Modular and Plug-and-Play Design

Each process stage — clarification, filtration, membranes, chemical dosing — is built as a separate module. Modules connect using flexible pipework, quick couplings, and plug-in electrical systems for rapid installation.

7.2 Footprint and Site Layout

Mining sites often have limited space near pits or tailings dams. Hire plants are designed to fit small footprints, be placed on temporary hardstands, and withstand harsh site conditions.

7.3 Materials of Construction

Corrosive mine waters (e.g., acidic drainage) require robust materials. Skids, tanks, and pipework are typically fabricated from stainless steel, HDPE, or coated carbon steel.

7.4 Automation and Control

Modern hire plants feature:

- PLC-based control panels for autonomous operation.

- Remote monitoring via SCADA or cloud dashboards.

- Automated alarms for critical parameters (e.g., pH, flow, turbidity).

- Integration with mine SCADA or DCS if required.

7.5 Instrumentation

Key online instruments include:

- pH, ORP, and conductivity probes.

- Turbidity and TSS sensors.

- Flow meters and totalizers.

- Pressure and level transmitters.

- Chemical dosing flow controllers.

7.6 Logistics and Access

Hire plants must be transportable by road or rail. Modules are designed to fit standard container dimensions and comply with weight restrictions for cranes or forklifts on-site.

7.7 Environmental and Safety Compliance

Designs must align with site HSE standards:

- Bunded chemical storage areas.

- Emergency spill containment.

- Safe access walkways, handrails, and lifting points.

- Noise and emissions controls if using powered units.

7.8 Commissioning and Demobilization

Quick hook-up points and clear documentation enable rapid commissioning and safe decommissioning, minimizing site downtime.

- Typical Applications and Case Studies

- Coal mining wastewater treatment

- Metal mines: gold, copper, iron ore

- Tailings pond water treatment

- Pit dewatering

- Acid mine drainage (AMD) treatment

- Operating and Maintenance Requirements

- Staffing and training

- Chemical supply and storage

- Sludge handling and disposal

- Routine and emergency maintenance

- Regulatory Framework and Permitting

- Local and international water quality standards

- Environmental permits

- Discharge consent limits

- Stakeholder engagement

- Commercial and Contract Models

- Rental agreement structures

- Service-level agreements (SLAs)

- Cost estimation and pricing models

- Insurance and risk allocation

- Emerging Trends and Innovations

- Smart metering and AI for predictive maintenance

- Energy-efficient desalination

- Resource recovery (metals, minerals, water reuse)

- Integration with renewable energy

- Challenges and Limitations

- Site access and mobility

- Remote operations

- High variability in wastewater composition

- Supply chain constraints

- Best Practices for Hiring a Water Treatment Plant

- Vendor selection criteria

- Technical due diligence

- Pilot trials and performance guarantees

- Community and environmental considerations