Advanced Water Separation from Oil Using Induced Gas Flotation (IGF) Integrated with IoT and Artificial Intelligence (AI)

Advanced Water Separation from Oil Using Induced Gas Flotation (IGF) Integrated with IoT and Artificial Intelligence (AI)

1. Introduction

Crude oil exploration and production inevitably involve the simultaneous extraction of water, oil, and gas. The presence of water, especially in the form of produced water, poses significant operational, economic, and environmental challenges. It is essential to separate this water efficiently to maintain production quality, reduce corrosion risks, protect equipment, and meet environmental compliance.

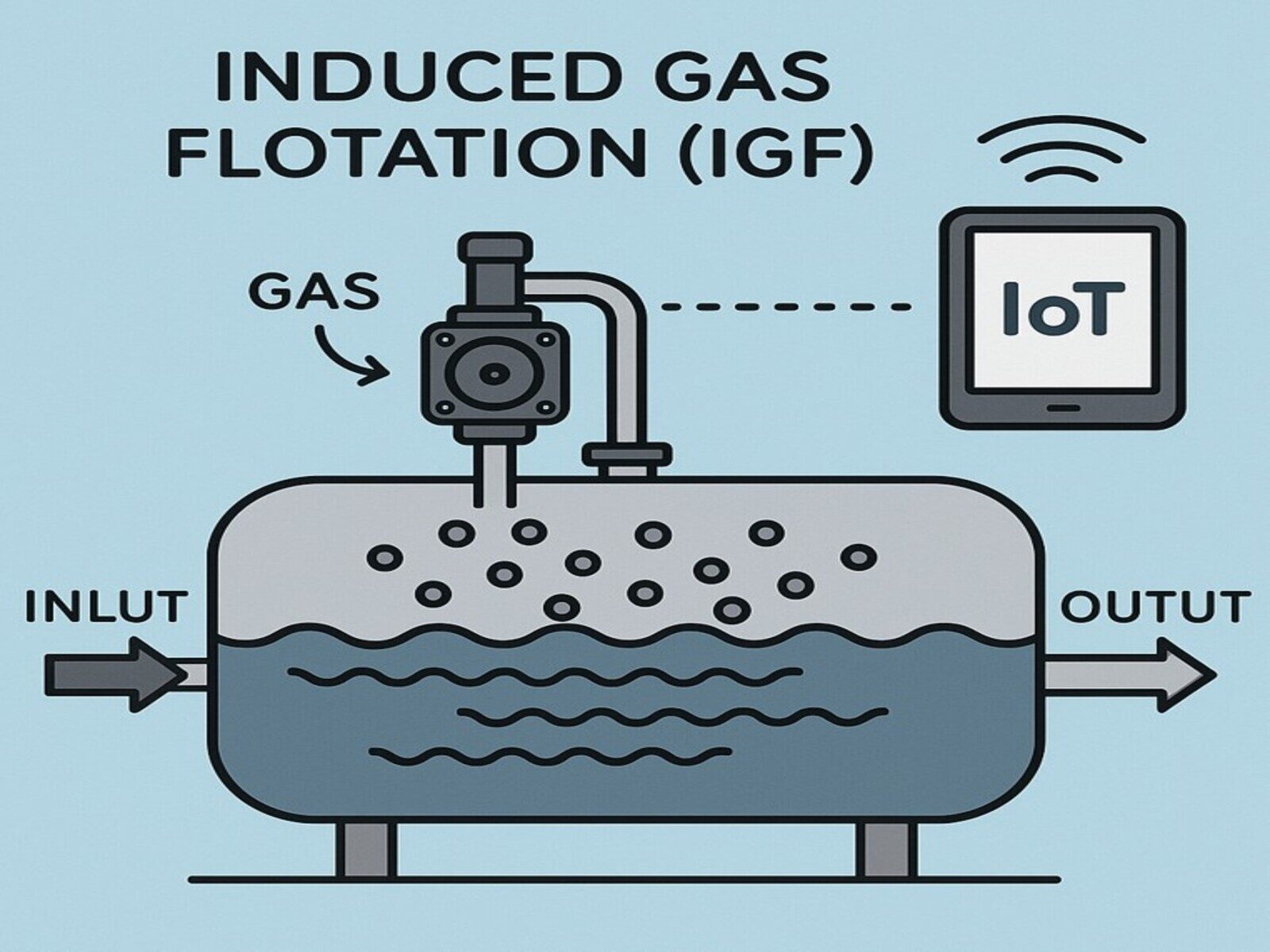

Induced Gas Flotation (IGF) is one of the most widely adopted technologies for removing free and dispersed oil from produced water. With the integration of the Internet of Things (IoT) and Artificial Intelligence (AI), the efficiency, control, and adaptability of IGF units can be greatly enhanced, enabling intelligent and autonomous water management systems in both manned and unmanned oilfield operations.

2. Overview of Induced Gas Flotation (IGF)

- Induced Gas Flotation (IGF) is a mechanical water treatment process that enhances the separation of oil and suspended solids from produced water. The core principle involves the injection of fine gas bubbles into the water stream. These bubbles attach to oil droplets and solid particles, increasing their buoyancy, causing them to rise to the surface, where they can be skimmed off.

- Key Components of IGF Units:

- Flotation Cells or Chambers: Large vessels where the flotation process occurs.

- Gas Injection System: Usually air or natural gas is dispersed using eductors or diffusers.

- Skimming Mechanism: Removes accumulated oil and solids from the surface.

- Recycle Pumps: Circulate a portion of the treated water to maintain turbulence and bubble formation.

- Control Valves and Flow Meters: Regulate flows within the system.

Limitations of Conventional IGF:

- Manual controls that lack responsiveness to real-time changes.

- Variable feed water composition affects performance.

- Requires skilled operator intervention.

- No predictive maintenance or failure forecasting.

3. Role of IoT in Enhancing IGF Performance

The integration of IoT enables real-time monitoring and control of every parameter involved in IGF operation.

Smart Sensors Deployed:

- Oil-in-Water (OIW) Analyzers: Monitor oil concentration before and after treatment.

- Flow and Pressure Sensors: Track inflow, recycle, and discharge streams.

- Bubble Size Sensors: Ensure optimal gas dispersion.

- Level Sensors: Detect oil, water, and sludge levels in flotation tanks.

- Conductivity & Salinity Sensors: Detect water quality changes.

- Temperature Sensors: Ensure optimal conditions for flotation.

IoT Infrastructure:

- Edge Devices: Aggregate sensor data and conduct preliminary analysis.

- Gateways and Communication Modules: Transmit data to central systems via Wi-Fi, LoRa, 4G/5G, or satellite.

- Cloud Platforms: Host analytical dashboards, remote-control systems, and historical data.

Benefits of IoT Integration:

- Real-time visibility into process parameters.

- Early detection of anomalies or performance decline.

- Automated reporting and alert systems.

- Enhanced safety through remote monitoring.

4. Role of Artificial Intelligence in Optimizing IGF Operation

Artificial Intelligence brings predictive and autonomous decision-making capabilities to IGF systems. By analyzing historical data, real-time sensor inputs, and operational rules, AI can optimize process variables for enhanced performance.

AI Applications in IGF:

- Predictive Analytics:

- Anticipate water quality changes and pre-emptively adjust gas flow or chemical dosing.

- Detect patterns that signal equipment wear, fouling, or process inefficiencies.

- Real-Time Process Optimization:

- Adjust gas injection rate and bubble size to match inflow composition.

- Optimize chemical injection based on real-time OIW levels.

- Manage skimming cycles based on sludge accumulation.

- Closed-Loop Control:

- Automate control valves, pumps, and gas flow based on sensor feedback.

- Achieve consistent effluent quality even during process disturbances.

- Energy and Chemical Use Optimization:

- Reduce energy consumption by adjusting pump speeds.

- Minimize chemical waste by targeting exact dosages.

Example: If OIW concentration at the IGF outlet starts increasing, AI algorithms can automatically:

- Increase air/gas injection rate.

- Adjust coagulant dosage.

- Extend retention time by slowing outlet flow.

- Trigger alerts if intervention thresholds are breached.

5. Integrated Architecture: IGF + IoT + AI

System Flow:

- Raw produced water enters the IGF system.

- IoT sensors monitor key parameters in real-time.

- Data is transmitted to an edge device and forwarded to AI platform.

- AI analyzes trends, predicts performance, and sends control signals.

- Actuators adjust the system: pumps, valves, gas dispersers, and skimmers.

- A dashboard displays current status, performance KPIs, and maintenance alerts.

Architecture Diagram (Text Representation):

Raw Water → [IGF Unit] ← [IoT Sensors] → [Edge Gateway] → [AI Engine] → [Pump/Valve/Skim Control] → [Effluent Output]

6. Field Applications and Case Scenarios

| Scenario | IoT + AI Impact |

| Offshore Production Platforms | Enables remote operation and monitoring of IGF systems where manual intervention is minimal. |

| Unmanned Well Pads | Supports autonomous IGF operation with predictive maintenance and fault detection. |

| High Water-Cut Fields | Enhances separation efficiency and reduces chemical costs in fields producing large water volumes. |

| Environmentally Sensitive Areas | Ensures water discharge remains within legal OIW limits (<30 ppm). |

7. Key Advantages of IGF with IoT and AI

- Improved Separation Efficiency: Maintains consistent OIW levels in treated water.

- Operational Autonomy: Ideal for unmanned or remote installations.

- Predictive Maintenance: Avoids unexpected downtime and improves equipment lifespan.

- Resource Optimization: Reduces use of gas, chemicals, and energy.

- Regulatory Compliance: Ensures treated water meets environmental discharge standards.

- Data-Driven Insights: Supports long-term planning and decision-making through data analytics.

8. Future Outlook

- Digital Twins: Create virtual models of IGF units to simulate behavior under different conditions.

- Edge AI: Bring low-latency decision-making directly to field devices.

- Blockchain Integration: Secure, traceable logging of water quality and system performance for regulatory audit.

- Sustainable Design: Use AI to reduce the environmental impact of water treatment processes.

9. Conclusion

The convergence of Induced Gas Flotation (IGF), IoT, and Artificial Intelligence represents a transformative approach to water management in oil exploration. By making IGF systems intelligent, adaptive, and autonomous, oilfield operators can achieve greater operational efficiency, environmental compliance, and cost savings. This is especially critical in the context of modern energy production, where digital transformation is a prerequisite for sustainability and profitability.

The future of water-oil separation is not just mechanical—it is digital, connected, and intelligent.