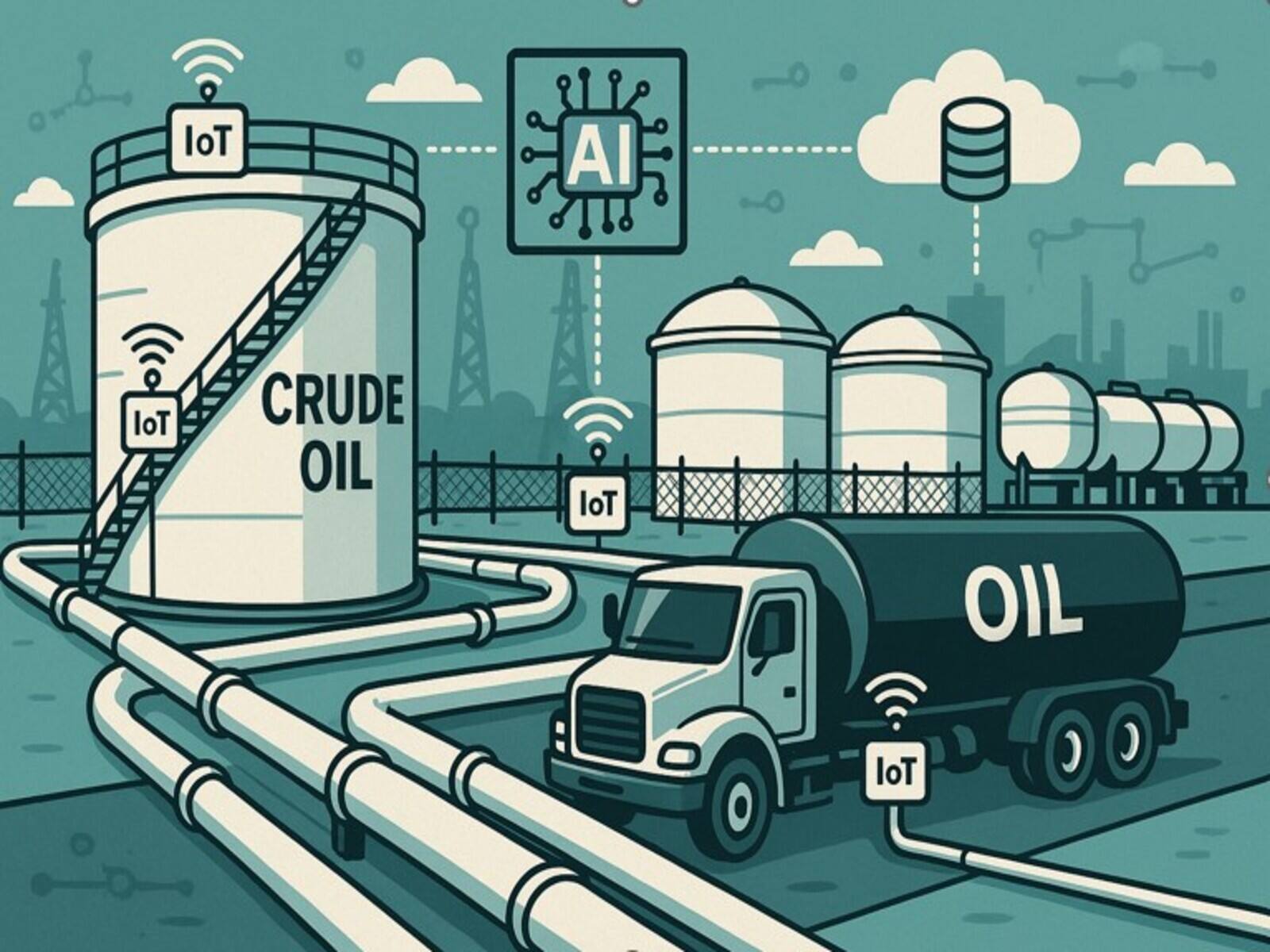

Use of IoT, ARTIFICIAL INTELLIGENCE, in Crude Oil Supply Pipelines and Distribution Lines

Use of IoT, ARTIFICIAL INTELLIGENCE, in Crude Oil Supply Pipelines and Distribution Lines

1. Overview

Crude oil pipelines, spanning thousands of kilometers, are critical infrastructure for transporting crude from production sites (wellheads, offshore rigs) to refineries and storage terminals. Traditionally monitored using SCADA systems and manual inspections, these pipelines are now being enhanced with IoT technologies to increase automation, real-time visibility, predictive maintenance, safety, and environmental compliance.

2. IoT System Architecture in Oil Pipelines

Layers:

| Layer | Description |

| Sensing Layer | Smart sensors deployed along pipelines (pressure, temperature, flow, vibration, corrosion, leak, gas, strain, etc.) |

| Network Layer | Communication via LoRaWAN, NB-IoT, cellular (3G/4G/5G), satellite, or fiber |

| Edge Computing Layer | Local data processing to reduce latency, enable fast decisions |

| Cloud Platform Layer | Centralized data storage, analytics, AI/ML-based prediction, visualization dashboards |

| Application Layer | Interfaces for monitoring, control, maintenance scheduling, alerts, and reporting |

3. Functional Applications

3.1 Real-Time Monitoring of Pipeline Health

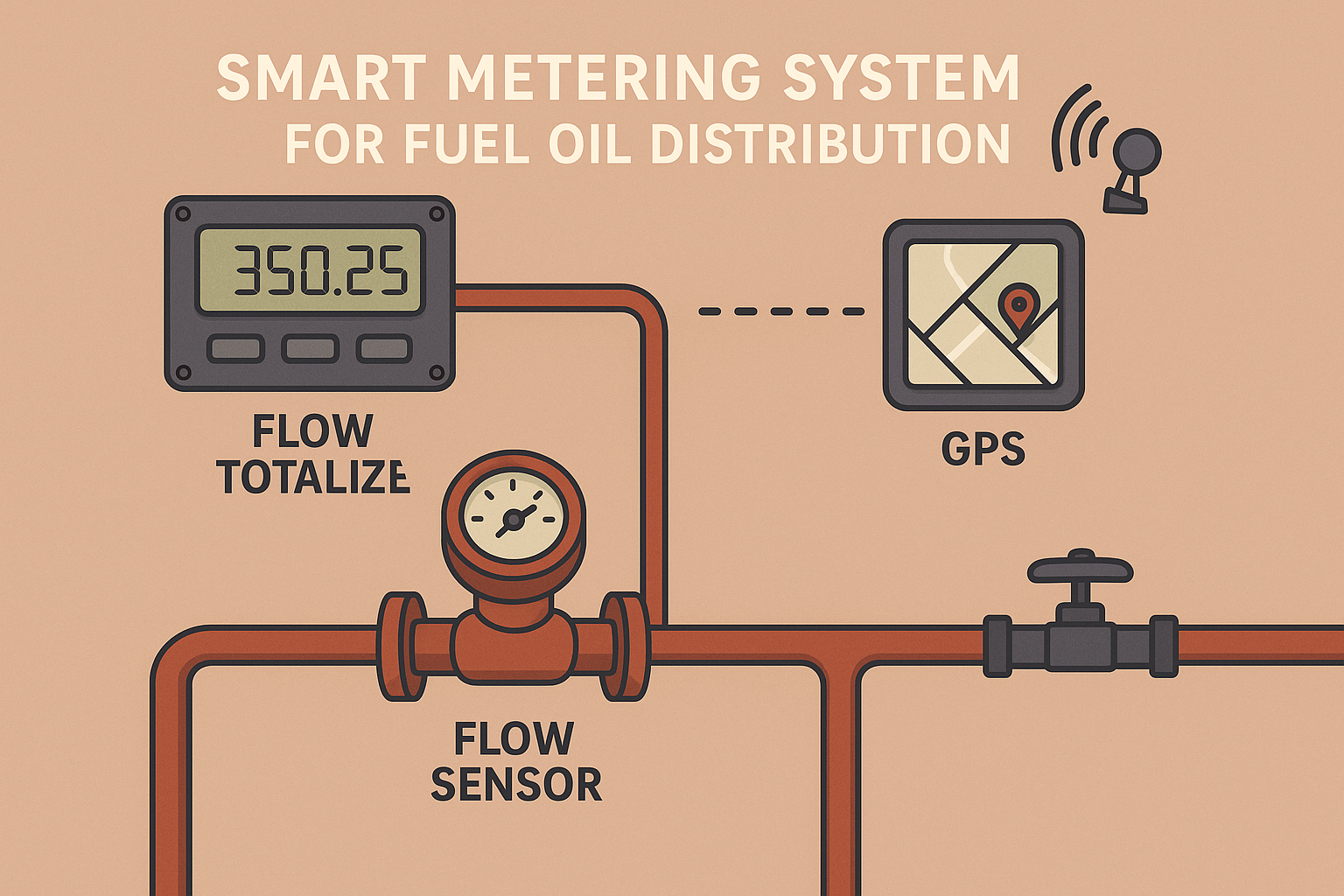

a. Flow and Pressure Monitoring

- Sensors placed at intervals measure the real-time flow rate and pressure.

- Sudden drops may indicate leaks, while pressure buildup could indicate blockages or valve malfunction.

b. Temperature Sensors

- Critical for tracking oil viscosity and pipeline heating requirements in cold climates.

- Helps optimize pump operations and avoid wax/hydrate formation.

c. Pump & Compressor Station Monitoring

- Embedded IoT devices monitor motor vibration, bearing temperature, RPM, and current draw.

- Anomalies are fed into predictive models to avoid failures.

3.2 Intelligent Leak Detection Systems (LDS)

IoT enhances traditional LDS by integrating multiple detection techniques:

- Pressure-wave analysis: Detects transient waves generated by leaks.

- Fiber-optic acoustic sensors: Detects changes in noise patterns and vibrations.

- Mass balance methods: Compares measured inflow and outflow.

- AI models analyze flow/pressure deviations and issue alerts within seconds.

Benefits:

- Reduces response time from hours to minutes.

- Geo-tagged leak location improves emergency response.

3.3 Corrosion and Structural Integrity Monitoring

- Electrochemical sensors and ultrasonic probes monitor wall thickness, pH, and corrosion rate inside pipelines.

- Strain gauges and accelerometers detect pipe bending, vibration, or settlement.

- Data trends are used in AI models to forecast failure points.

Applications:

- Enables condition-based maintenance (CBM).

- Prevents catastrophic failures due to corrosion under insulation (CUI) or stress cracking.

3.4 Intrusion and Tampering Detection

- Ground vibration sensors, thermal cameras, motion detectors, and magnetometers are deployed along the pipeline’s Right-of-Way (ROW).

- Drones or fixed IoT surveillance units with AI vision detect:

- Illegal tapping

- Unauthorized excavation

- Vehicle movement near pipelines

Alerts are instantly relayed to security teams.

3.5 Predictive Maintenance and Asset Lifecycle Management

Using data from sensors, IoT platforms:

- Train machine learning (ML) models to predict:

- Valve wear

- Pump seal failure

- Sensor drift

- Power system degradation

- Combine equipment logs, operating hours, and vibration patterns for reliability-centered maintenance (RCM).

Digital Twin:

A virtual replica of the pipeline and its assets that simulates:

- Future performance

- Failure scenarios

- Maintenance cost optimization

3.6 Energy Optimization

- IoT systems adjust pump speed, valve position, and compressor load based on:

- Real-time demand

- Pipeline elevation

- Crude characteristics (viscosity, temperature)

AI analytics suggest least energy-intensive routes or optimal pumping sequences, cutting power costs significantly.

3.7 Environmental Monitoring

- Gas sensors monitor methane, hydrogen sulfide (H₂S), and VOCs.

- Air and water quality sensors placed along the ROW detect:

- Spills

- Groundwater contamination

- Airborne hydrocarbon release

Alerts trigger automatic valve shut-off and dispatch of emergency teams.

3.8 Remote Control and Automation

- IoT-connected actuated valves and motorized pig launchers can be controlled remotely.

- SCADA systems receive data from IoT devices for supervisory control.

- Pipelines in remote regions can be fully automated with minimal manual intervention.

4. Integration with Advanced Technologies

Blockchain for Data Integrity

- Pipeline custody transfer data is timestamped and stored immutably.

- Enhances transparency in metering and billing.

Cloud and Edge Hybrid Architecture

- Real-time data is processed at edge gateways for critical events.

- Long-term trends and analytics are handled in cloud platforms (Azure, AWS IoT, Google Cloud IoT).

AI and Machine Learning

- Predicts corrosion hotspots, leak probabilities, energy usage patterns.

- Learns from historical data to reduce false alarms and optimize operations.

5. Example Use Case: IoT Pipeline Monitoring in Remote Desert

| Feature | IoT Implementation |

| Sensors | Pressure, temp, flow, corrosion, vibration, gas leak |

| Communication | LoRaWAN to gateway → Satellite uplink to cloud |

| Power | Solar-powered nodes with battery backups |

| Edge Device | Local processing of anomalies |

| Cloud Platform | SCADA dashboard, alerts, AI-driven forecasts |

| Security | Blockchain for sensor data integrity |

6. Benefits

| Area | Benefit |

| Safety | Early leak detection, hazard alerts, automated shutoffs |

| Efficiency | Optimized throughput, reduced energy use |

| O&M Costs | Less unplanned downtime, fewer manual inspections |

| Asset Life | Condition-based maintenance extends pipeline life |

| Compliance | Automated reporting to regulators (EPA, ISO, API) |

| Visibility | Real-time centralized monitoring from anywhere |

7. Challenges and Mitigation

| Challenge | Mitigation |

| Remote location power supply | Solar + battery nodes |

| Cybersecurity | Encrypted data, access control, anomaly detection |

| Legacy system integration | IoT-SCADA gateways, OPC-UA adapters |

| Data overload | Edge computing to preprocess and filter data |

| Sensor drift/failure | Auto-calibration, redundancy, diagnostics |

Conclusion

The deployment of IoT in crude oil pipelines is transforming the sector into a smarter, safer, and more efficient infrastructure system. With continuous monitoring, data-driven decision-making, and AI-assisted maintenance, pipeline operators can significantly enhance reliability, reduce environmental risks, and lower operational costs.