Multi-Effect Distillation with Thermal Vapour Compression for Seawater Desalination

Multi-Effect Distillation with Thermal Vapour Compression for Seawater Desalination

Table of Contents

- Introduction

- Overview of Desalination Technologies

- Principles of Multi-Effect Distillation (MED)

- Thermal Vapour Compression (TVC) Technology

- Integration of MED with TVC

- Design and Operational Aspects of MED-TVC Systems

- Thermodynamic Analysis and Energy Efficiency

- Advantages of MED-TVC over Other Desalination Methods

- Limitations and Challenges of MED-TVC Systems

- Materials of Construction

- Instrumentation and Control in MED-TVC Plants

- Environmental Impact and Sustainability

- Case Studies of MED-TVC Installations Worldwide

- Economic Evaluation and Cost Analysis

- Future Prospects and Technological Developments

- Conclusion

- References

1. Introduction

Seawater desalination through Multi-Effect Distillation with Thermal Vapour Compression (MED-TVC) is a process designed to produce fresh water from saline feedwater sources such as seawater. The increasing demand for potable water in arid regions, coupled with the depletion of freshwater resources, has led to the widespread adoption of MED-TVC desalination plants in countries with abundant thermal energy, like those in the Middle East. MED-TVC integrates both thermal and mechanical energy recovery techniques to increase overall energy efficiency and minimize operational costs, making it a favored solution where energy subsidies exist.

2. Overview of Desalination Technologies

Several desalination processes are used worldwide, each with specific merits and limitations:

- Reverse Osmosis (RO): Utilizes semi-permeable membranes and high-pressure pumps.

- Multi-Stage Flash (MSF): Relies on successive flashing of water at reduced pressures.

- Multi-Effect Distillation (MED): Employs multiple evaporation-condensation stages.

- Electrodialysis (ED): Applies electrical potential to remove ions from water.

- Hybrid systems: Combinations like MED-RO or MSF-RO for enhanced efficiency.

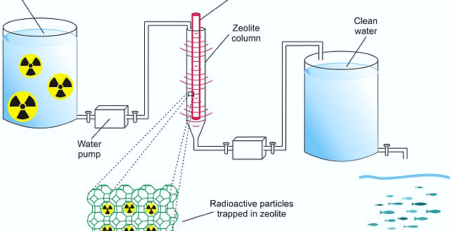

3. Applications of AI in Sewer Treatment

The MED process is based on the evaporation of seawater in a series of effects (stages), each operating at a lower pressure than the previous one. Steam heats the first effect; the evaporated vapor from this effect becomes the heating medium for the next, and so on, allowing efficient reuse of thermal energy. The temperature difference drives the evaporation, and the process is enhanced by maintaining a non-equilibrium allowance and optimizing heat transfer across tube bundles.

4. Thermal Vapour Compression (TVC) Technology

TVC improves MED efficiency by recompressing vapor from the later effects using high-pressure motive steam in a steam ejector. This compressed vapor is reintroduced to the system as a heating medium, reducing the requirement for fresh steam. TVC designs are optimized for ejector geometry, motive steam pressure, and mixing efficiency to minimize energy input.

5. Integration of MED with TVC

MED-TVC systems exploit the synergy between multiple-effect heat recovery and vapor compression. The motive steam ejects and entrains vapor, recompressing it for use in the first or subsequent effects, thus significantly reducing specific steam consumption. Process diagrams reveal reduced energy and freshwater production costs compared to standalone MED or MSF systems.

6. Design and Operational Aspects of MED-TVC Systems

- Pre-treatment: Seawater filtration and chemical dosing to prevent scaling.

- Evaporator/Condenser Design: Large heat transfer surfaces and optimal tube arrangements.

- Heat Exchangers: High efficiency for energy recovery.

- Brine Management: Strategies to control brine concentration and disposal.

- Scaling Control: Anti-scalants and periodic cleaning to ensure heat transfer integrity.

7. Thermodynamic Analysis and Energy Efficiency

Energy efficiency in MED-TVC is evaluated by:

- First and Second Law Analyses: To assess exergy losses and system irreversibilities.

- Gain Output Ratio (GOR): A measure of the kilograms of distillate produced per kilogram of steam input, typically ranging between 8–15 for MED-TVC systems.

- Energy Consumption: Specific energy consumption (SEC) values are significantly lower than MSF, with potential integration of waste heat sources for further gains.

8. Advantages of MED-TVC over Other Desalination Methods

- Operates at lower temperatures (60–70°C), reducing scaling risk.

- Superior thermal efficiency due to vapor reuse.

- Lower energy consumption compared to MSF.

- Ability to modulate production rates easily.

- Less sensitive to feedwater salinity than RO.

9. Limitations and Challenges of MED-TVC Systems

- High initial capital expenditure.

- Maintenance-intensive due to scaling and corrosion risks.

- Requires stable steam sources, such as from cogeneration plants.

- Brine disposal remains an environmental concern, demanding careful management.

10. Materials of Construction

Material selection is critical due to corrosive seawater and thermal cycling:

- Duplex and Super Duplex Stainless Steels: High corrosion resistance.

- Titanium Alloys: For high-salinity resistance.

- Polymeric Materials: Used in certain auxiliary components to reduce cost.

11. Instrumentation and Control in MED-TVC Plants

Control systems optimize operation:

- Sensors: Temperature, pressure, flow rate for process monitoring.

- Steam Ejector Monitoring: For performance validation.

- Distributed Control Systems (DCS): Integrated process automation.

- Predictive Maintenance: AI and IoT-based systems for anomaly detection.

12. Environmental Impact and Sustainability

- Carbon Footprint: Lowered via waste heat use or renewable energy integration.

- Brine Disposal: Proper dilution and discharge strategies to minimize marine ecosystem impact.

- Resource Recovery: Potential extraction of valuable salts from brine.

13. Case Studies of MED-TVC Installations Worldwide

- Middle East: Largest installed capacities in UAE, Saudi Arabia.

- North Africa: Egypt adopting MED-TVC in coastal areas.

- Europe: Pilot projects in Spain and Italy.

- Asia: Growing interest in India and China due to water stress.

14. Economic Evaluation and Cost Analysis

- CAPEX: High, but offset by lower OPEX.

- OPEX: Reduced through energy recovery.

- Levelized Cost of Water (LCW): Competitive in energy-abundant regions.

- Cost Comparison: Favorable versus MSF, more expensive than RO unless waste heat is used.

15. Future Prospects and Technological Developments

- Advanced Materials: To improve corrosion resistance.

- Hybrid Systems: MED-TVC coupled with RO for higher efficiency.

- Solar Integration: Solar thermal energy to drive MED-TVC.

- Digitalization: AI-driven predictive maintenance and process optimization.

16. Conclusion

MED-TVC desalination remains one of the most sustainable and reliable technologies for seawater desalination, especially suited to energy-rich arid regions. Ongoing research into material science, hybridization, and renewable integration is expected to enhance system efficiency, reduce costs, and mitigate environmental impacts, securing its future relevance in global water security.

17. References

[To be populated with detailed academic, industrial, and standards references in the final document.]