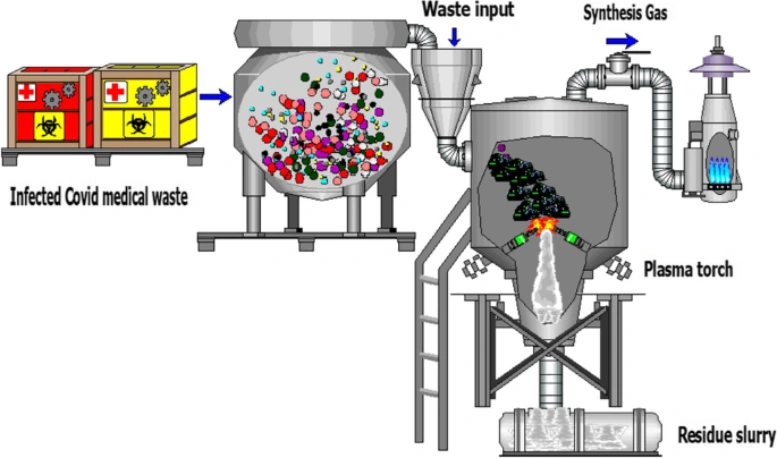

Plasma pyrolysis is a waste treatment technology that utilizes high-temperature plasma to convert organic materials into useful products while minimizing harmful emissions. It is an advanced form of pyrolysis, which is the thermal decomposition of organic compounds in the absence of oxygen. Plasma pyrolysis involves subjecting the waste materials to a plasma arc, an electrically conductive gas composed of ions, electrons, and neutral particles.

Steps Involves

The process of plasma pyrolysis typically involves the following steps:

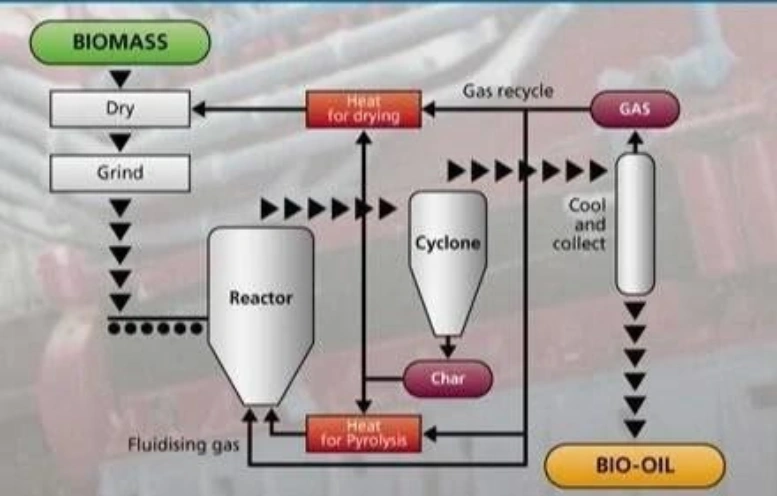

A. Waste Preprocessing:

The waste material, such as biomass, municipal solid waste, or hazardous waste, is first sorted and prepared for treatment. This may involve shredding or grinding the waste to increase its surface area and facilitate efficient processing.

B. Plasma Generation:

A plasma arc is created by subjecting a gas, such as argon or nitrogen, to high temperatures and electrical energy. This creates a highly energized and ionized gas stream known as plasma.

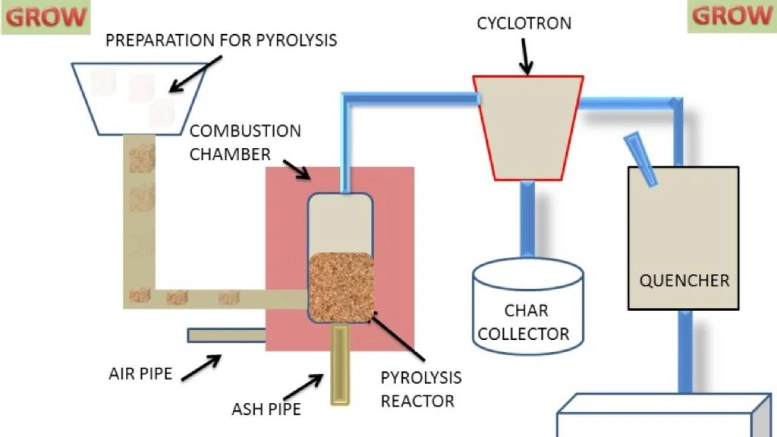

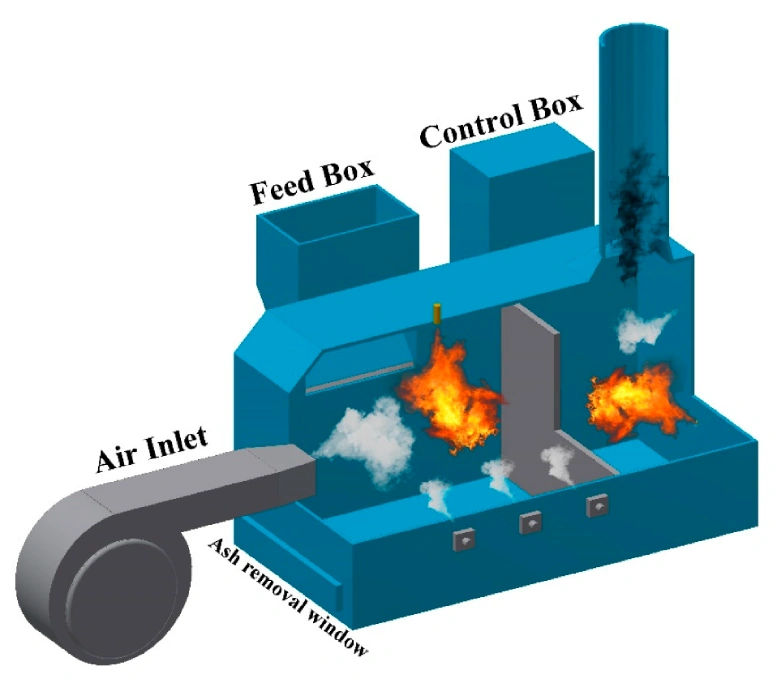

C. Plasma Reactor:

The waste material is introduced into the plasma reactor, where it comes into contact with the high-temperature plasma. The intense heat of the plasma causes the organic compounds in the waste to undergo thermal decomposition or pyrolysis.

D. Decomposition and Transformation:

As the waste material is exposed to the plasma, it is rapidly heated to very high temperatures, typically exceeding 3,000 degrees Celsius. This thermal energy breaks down the complex organic molecules into simpler compounds, including gases, liquids, and solid residues.

E. Product Recovery:

The resulting products of plasma pyrolysis include syngas (a mixture of hydrogen, carbon monoxide, and other gases), liquid fuels, such as bio-oils, and solid residues, such as char or ash. These products can be further processed or refined for various applications, including energy generation, chemical production, or as feedstocks for other industrial processes.

Advantages Over Traditional Incineration

Plasma pyrolysis offers several advantages over traditional incineration or landfilling methods. It can effectively handle a wide range of waste types, including hazardous and non-recyclable materials. The high temperatures of plasma pyrolysis can break down complex organic compounds, including persistent organic pollutants (POPs), into simpler and less harmful forms. Additionally, the process generates energy-rich products like syngas, which can be used to produce electricity or heat.

However, it's worth noting that plasma pyrolysis is a complex and technologically advanced process. It requires specialized equipment and control systems to maintain the high-temperature plasma and ensure efficient and safe operation. The capital and operational costs associated with plasma pyrolysis systems can be significant, and the technology is still being developed and optimized for commercial-scale applications.

Capabilities and Expertise

When considering a plasma pyrolysis system manufacturer, it's important to focus on their capabilities and expertise in waste-to-energy, waste-to-fuel, waste-to-gas, and waste incineration technologies. Here are the key points to consider:

1) Waste-to-Energy:

The manufacturer should have a track record of designing and manufacturing plasma pyrolysis systems that effectively convert waste materials into energy. This includes the ability to handle different types of waste, such as municipal solid waste, biomass, industrial waste, or hazardous waste, and efficiently extract energy from them using plasma technology.

2) Waste-to-Fuel:

A reputable manufacturer should have experience in developing plasma pyrolysis systems that can convert waste materials into useful fuels. This involves the production of liquid fuels, such as bio-oils, or the generation of syngas that can be further processed into fuels like hydrogen or synthetic natural gas (SNG). The ability to optimize the system for fuel production and ensure high-quality fuel outputs is crucial.

3) Waste-to-Gas:

The manufacturer should demonstrate expertise in transforming waste materials into valuable gases through plasma pyrolysis. This includes the production of syngas, which can be used for power generation, heating, or as a feedstock for various industrial processes. The system should be designed to efficiently convert waste into gases and recover the maximum possible value from the gas stream.

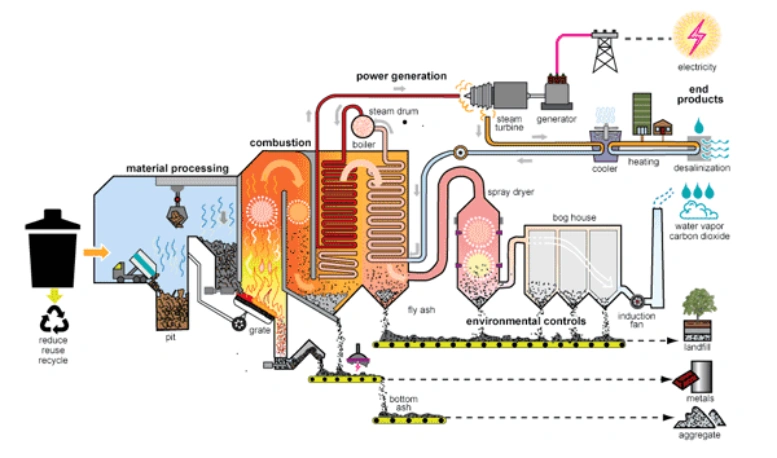

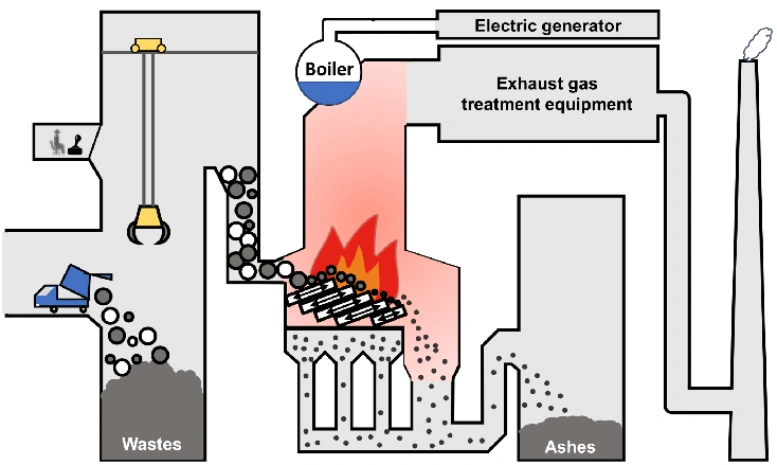

4) Waste Incineration:

While plasma pyrolysis is distinct from traditional waste incineration, some manufacturers may offer integrated systems that combine plasma pyrolysis with incineration capabilities. This enables the treatment of a wider range of waste streams and ensures efficient and environmentally sound disposal of waste materials.

Important Factors

Other important factors to consider when choosing a plasma pyrolysis system manufacturer include:

Technical Expertise:

The manufacturer should have a team of experts knowledgeable in plasma technology, waste treatment, and engineering to ensure the design, construction, and operation of the systems meet high standards.

Compliance and Environmental Performance:

The manufacturer should adhere to relevant environmental regulations and prioritize the reduction of emissions and the safe handling of waste materials. Consider their track record in achieving environmental compliance and the efficiency of their systems in minimizing emissions and pollutants.

Customization and Scalability:

Look for a manufacturer that can tailor the plasma pyrolysis systems to meet specific waste types and processing requirements. Additionally, consider their ability to scale up the systems for larger waste volumes if needed.

Support and Maintenance:

Evaluate the manufacturer's after-sales support, including technical assistance, maintenance services, and spare parts availability. A reliable manufacturer should offer ongoing support to ensure the optimal performance and longevity of the plasma pyrolysis systems.

Types of Waste

Plasma pyrolysis is a versatile waste treatment technology that can effectively handle various types of waste, including biomedical waste, petrochemical waste, chemical waste, pesticide waste, pharmaceutical waste, and a wide range of industrial wastes. Here are the details on how plasma pyrolysis can be useful for these waste categories:

1. Biomedical Waste:

Biomedical waste, such as medical instruments, syringes, gloves, and other healthcare-related materials, often contains hazardous substances and pathogens. Plasma pyrolysis can efficiently treat biomedical waste, ensuring safe disposal and minimizing the risk of contamination. The high temperatures of plasma pyrolysis can destroy pathogens and neutralize hazardous substances, converting the waste into less harmful byproducts.

2. Petrochemical Waste:

Petrochemical waste encompasses various residues generated during petroleum refining, oil and gas production, or chemical manufacturing processes. This waste often contains hydrocarbons, heavy metals, and other pollutants. Plasma pyrolysis offers an effective method to treat petrochemical waste by breaking down complex hydrocarbons into simpler compounds, recovering valuable materials, and minimizing environmental contamination.

3. Chemical Waste:

Chemical waste includes residues from laboratories, industrial processes, and chemical manufacturing. These wastes can be highly toxic, reactive, or corrosive. Plasma pyrolysis can handle chemical waste by subjecting it to high temperatures, causing the breakdown of complex chemical compounds into less harmful substances. It can also recover valuable chemicals or convert them into energy-rich gases or liquids.

4. Pesticide Waste:

Pesticide waste poses significant environmental and health risks due to its toxic nature. Plasma pyrolysis can effectively treat pesticide waste by thermally decomposing the hazardous compounds into simpler forms. The process can neutralize or destroy the active ingredients in pesticides, reducing their toxicity and minimizing the environmental impact.

5. Pharmaceutical Waste:

Pharmaceutical waste, including expired drugs, unused medications, and pharmaceutical production residues, requires specialized treatment to prevent their release into the environment. Plasma pyrolysis can provide a suitable solution by converting pharmaceutical waste into energy-rich products like syngas or recovering valuable chemicals for proper disposal or reuse.

6. Industrial Wastes:

Plasma pyrolysis is capable of treating a wide range of industrial wastes, including manufacturing residues, electronic waste, plastic waste, and more. By subjecting these wastes to high-temperature plasma, it can break down complex organic compounds, convert plastics into syngas or liquid fuels, and recover valuable materials for recycling or further processing.

Advantages

Plasma pyrolysis offers several advantages for these waste categories. It can efficiently and safely handle hazardous and complex waste streams, minimize harmful emissions, and recover valuable resources. The technology's ability to operate at high temperatures allows for the effective destruction, decomposition, or transformation of various waste materials, ensuring a more sustainable approach to waste management.

Applications of plasma pyrolysis system

Certainly, plasma pyrolysis is a useful technology for generating useful gases, combustible oils, and waste-to-energy plants. Here's a further explanation of these applications:

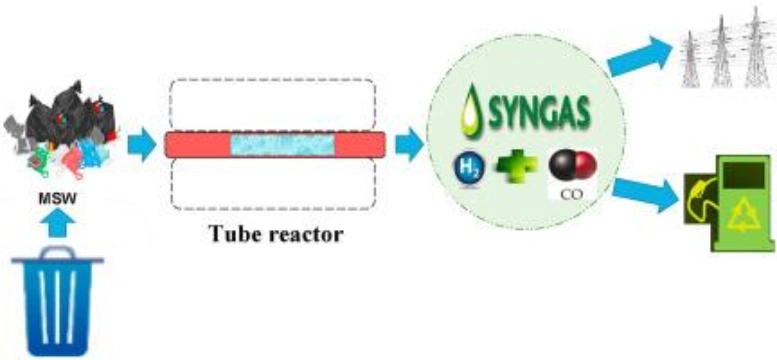

1. Useful Gases:

Plasma pyrolysis can efficiently convert various types of waste into useful gases. The high temperatures and intense heat of the plasma can break down organic compounds present in the waste, resulting in the production of syngas (synthesis gas). Syngas primarily consists of hydrogen (H2) and carbon monoxide (CO), along with other trace gases. Syngas is a valuable resource that can be used for several purposes, such as:

- Power Generation:

Syngas can be used as a fuel in gas turbines or internal combustion engines to produce electricity.

- Heating:

Syngas can be burned to generate heat for industrial processes or district heating systems.

- Chemical Production:

Syngas serves as a feedstock for the production of various chemicals, such as methanol, ammonia, and synthetic fuels.

2. Combustible Oils:

Plasma pyrolysis can also produce combustible oils or bio-oils from certain types of waste, such as biomass or organic waste. The intense heat of the plasma causes the organic compounds in the waste to break down and form a liquid product. This bio-oil contains a range of hydrocarbons that can be used as a fuel source. It can be further refined and processed to remove impurities and enhance its fuel properties, making it suitable for applications such as:

- Energy Generation:

Combustible oils can be burned directly in boilers or converted into heat or electricity through combustion or gasification processes. - Industrial Applications:

Combustible oils can be utilized as a substitute for fossil fuels in various industrial processes, including heating, steam generation, or as a feedstock for chemical production.

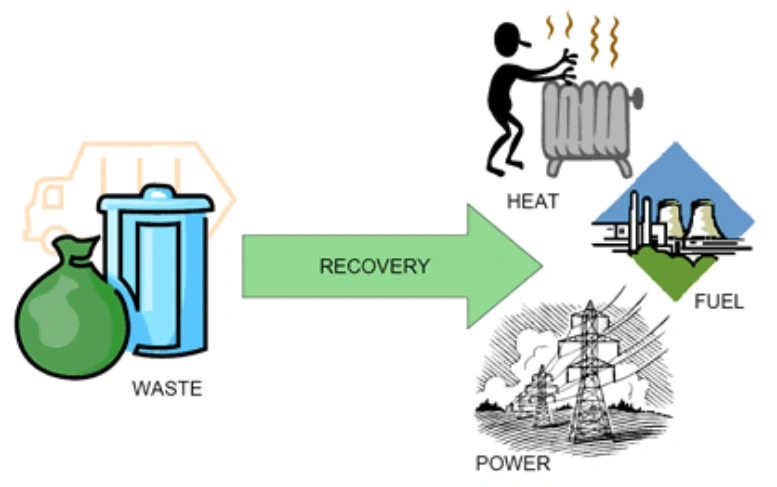

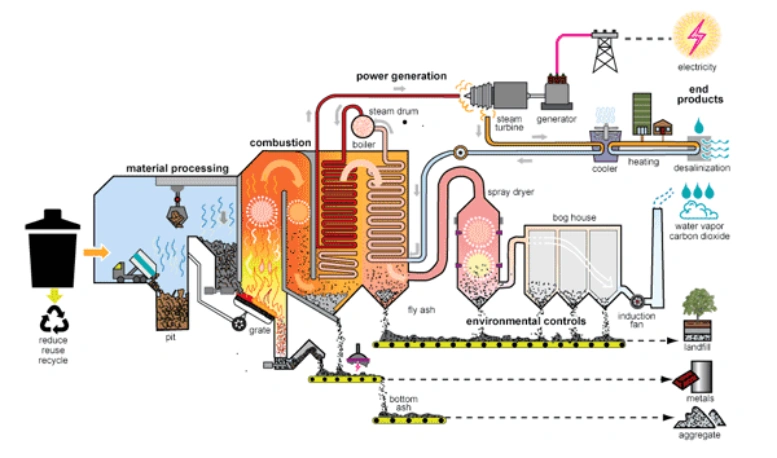

3. Waste-to-Energy Plants:

Plasma pyrolysis serves as a foundation for waste-to-energy plants. These plants are designed to efficiently convert waste materials into usable energy, reducing the dependency on fossil fuels and diverting waste from landfills. Plasma pyrolysis is an integral part of waste-to-energy systems, as it enables the thermal decomposition of waste, generating syngas, combustible oils, or other energy-rich byproducts.

Waste-to-energy plants employing plasma pyrolysis can offer several benefits, including:

- Energy Recovery:

The conversion of waste into useful energy resources helps meet the growing energy demands and reduces reliance on fossil fuels.

- Waste Reduction:

By treating and converting waste into energy, waste-to-energy plants contribute to reducing landfill volumes and associated environmental issues.

- Environmental Impact:

Plasma pyrolysis can help minimize harmful emissions, such as greenhouse gases and pollutants, through efficient combustion or gasification of waste materials.

Besides generating useful gases, combustible oils, and waste-to-energy plants, plasma pyrolysis can have additional applications, including the recovery of valuable metals from electronic waste, the treatment of contaminated soil or sludge, and the destruction of hazardous or persistent organic pollutants (POPs) in industrial waste streams. The versatility of plasma pyrolysis makes it a promising technology for sustainable waste management and resource recovery.